Maintenance, 3 fault diagnosis – Glow-worm Clearly Solar Cylinders User Manual

Page 26

0020115479_03 - 10/12 - Glow-worm

- 24 -

MAINTENANCE

11.3 fault diagnosis

The following checks should be performed before proceeding

onto specific diagnostics:

11.3.1

The faults described in this chapter should be carried

out by an engineer qualified to work on unvented

systems.

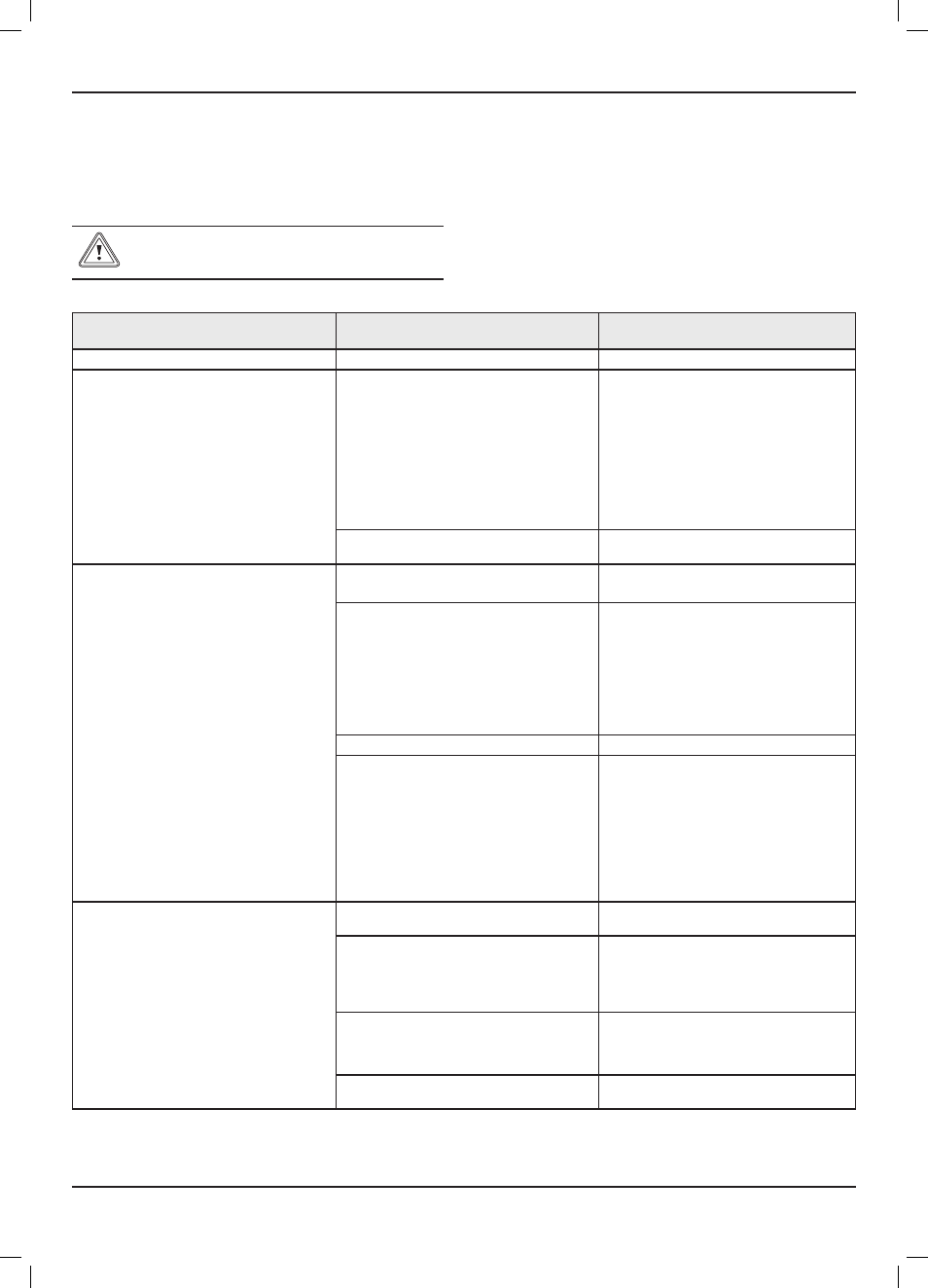

Malfunction

Cause

solution

Cylinder

The cylinder cools down at night.

After the solar pump is switched off, the

supply and return lines have different

temperatures.

The collector temperature is

higher than the air temperature at night.

1. The anti-siphon valve is blocked.

1. Check the position of the blue handle.

2. Check the anti-siphon valve for tightness

(jammed cuttings, particles of dirt in the

sealing face).

3. Do not connect the solar heat exchanger

directly; instead, first pull the supply lines

downwards and then upwards to the collector

(the siphon supports the antisiphon

valve) or mount a 2-way valve

which is switched at the same time as the

solar pump.

2. One-pipe circulation in the case of short

tube networks with low pressure loss.

Install an anti-siphon valve (as close as possible

to the cylinder).

Reheating is not working. The Gas-fired

boiler runs for a short time,

goes off and then back on again. This is

repeated until the cylinder is at its target

temperature.

1. Air in the reheating heat exchanger

Bleed the reheating heat exchanger.

1. The cold and hot water connections

on the cylinder have been mixed up.

Turn off the cold water supply, then let water

flow out via the hot water connection. Only a few

litres of water flow out if the connection is laid

correctly. The hot water withdrawal pipe intake

is then in the air space and further draining

is not possible. If it is possible to empty the

entire cylinder via the hot water connection, the

connections have been laid incorrectly.

Change the connections!

2. Hot water thermostat mixer set too low.

Increase the setting.

3. Solar heating insufficient; gas-fired boiler does

not reheat.

External control device is faulty.

Air in the reheating heat exchanger.

Cylinder sensor is faulty.

Check whether the gas-fired boiler is working.

Check whether the external control device is

working.

Check that the 2-way valve is in the DHW

position. Replace the 2-way valve.

Bleed the reheating heat exchanger.

Check the safety thermostat and suppress the

fault.

Replace the cylinder thermostat.

Water flows out of the expansion relief

valve (only when heating up).

Dirt on the valve seat of the expansion

relief valve.

Check the seat of the expansion relief valve and

suppress the fault.

Pressure limiting valve is faulty.

If water only escapes during heating, switch

off the gas-fired boiler and electric immersion

heater and check whether the pressure behind

the pressure limiting valve is lower than 3.0 bar.

If so, replace the pressure limiting valve.

Expansion vessel is faulty.

Check the pressure in the expansion vessel.

If the pressure is insufficient, reestablish the

pressure and check whether the expansion

vessel maintains it.

Expansion relief valve is faulty.

If the pressure is normal, replace the expansion

relief valve.