Maintenance, 11 inspection and maintenance – Glow-worm Clearly Solar Cylinders User Manual

Page 25

0020115479_03 - 10/12 - Glow-worm

- 23 -

MAINTENANCE

MaINTeNaNCe

11 Inspection and maintenance

Glow-worm solar systems are designed to give a long trouble free

life.

In order to ensure this, an annual inspection of the solar circuit

should be carried out by a competent person approved at the time

by the Health and Safety executive . This would be carried out at

the same time as the boiler and cylinder inspection and comprise

mostly of visual checks.

Inspection access to the cylinder is available through the

immersion heater boss.

Where secondary return circuits are used then an additional

expansion vessel may be required.

The essential maintenance work on the solar system and

corresponding maintenance intervals are specified in the

following table.

After servicing, the servicing engineer must complete the relevant

Service Interval Record section of the Benchmark Checklist

located on the inside back pages of this document.

When replacing parts, only use original replacement

parts from Glow-worm.

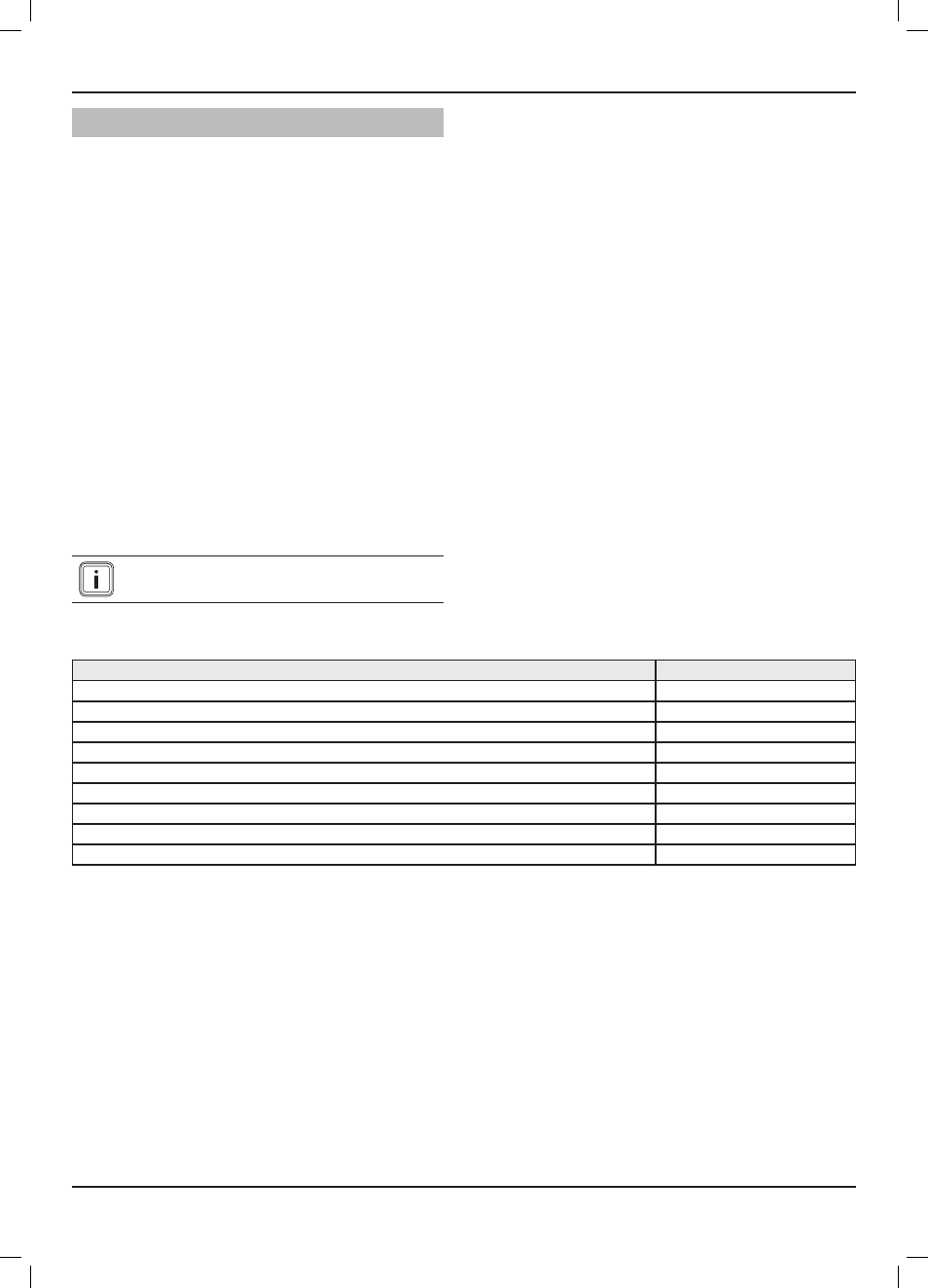

11.1 Maintenance checklist

Nature of maintenance work

Maintenance interval

Cylinder

Check all connections to ensure no leaks

Annually

Check the temperature and pressure relief valve

Annually

Checking the expansion relief valve

Annually

Check the charge pressure of the hot water expansion vessel, re-pressurise as necessary

Annually

Check water flow rates are correct (Check and clean filters as necessary)

Annually

Ensure set temperatures are correct

Annually

Check the hot water thermostat mixer function

Annually

Fill in the service section of the benchmark cylinder commissioning checklist

Annually

11.2 Draining the cylinder

• Close the cold water feed line.

• Secure a hose to the drain valve.

• Place the free end of the hose in a suitable discharge position.

The opening should be around 1 m beneath the cylinder.

• Open the highest hot water draw-off point to reduce the

pressure and bleed the water pipes, thus draining them

completely.

• Open the cylinder drain valve and leave open until no more

water escapes and the cylinder is completely empty.

• Once the water has drained out, close the hot water draw-off

point and the drain valve.

• Remove the hose from the drain valve.