Maintenance, 16 servicing – Glow-worm Clearly Heat Pump 5 kW User Manual

Page 27

0020111744_00 - 09/10 - Glow-worm

- 25 -

MAINTENANCE

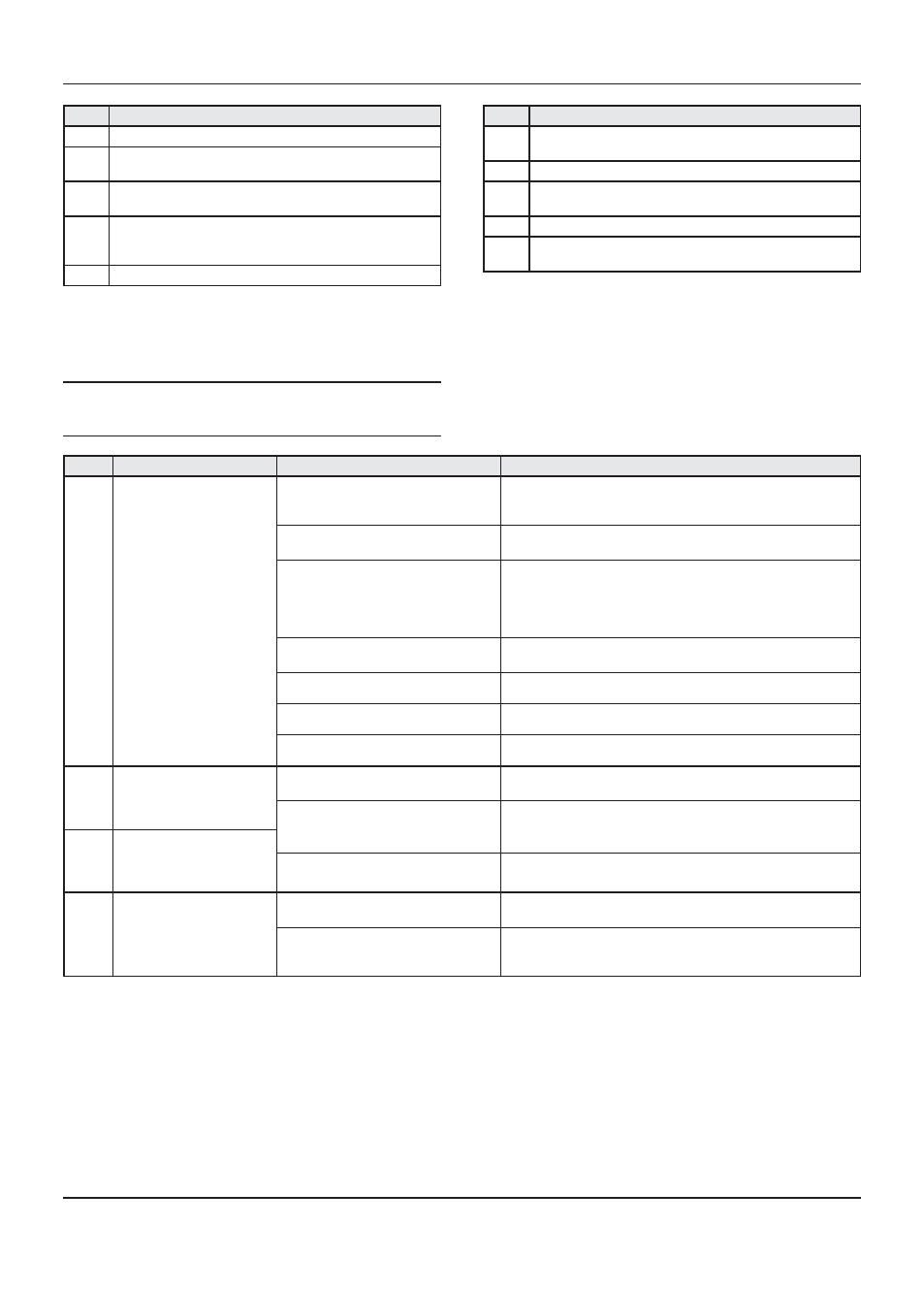

Status Description

34

Degassing of pump (20s OFF).

35

Failure of current to the motor’s electronic expansion valve

(blocking failure).

36

The 4-way cycle inversion valve is in the cooling position for

5 seconds.

37

Failure of compressor output temperature: does not surpass

2K upon start-up of compressor (blocking failure after 3

attempts).

38

Fan failure, speed too low (blocking failure after 3 attempts).

i

The status’ described in the table below must

be dealt with by a qualifi ed professional and, if

necessary, by the after-sales service.

Status Description

Cause

Solution

24

Poor fl ow in the brine circuit

following the pre-scan of

brine circuit pump

(D < 500 l/h).

The brine circuit fl ow is too low.

Force the pump and check the fl ow.

Adjust the water fl ow by changing the speed of the pump or

opening the hydraulic module control valve.

The brine circuit fl ow is too high or there

is a faulty indication of fl ow.

Check that there is no water fl ow by closing a valve in the brine

circuit. Force the pump and check the fl ow.

The water pump is defective.

Is the water pump hot? Measure the coil resistance. Replace the

pump motor.

Check the 230 V power supply to the pump.

Change the electrical panel.

Check the reading of the water fl ow when stopping the pump.

There is a lack of water.

Check the brine circuit. If the valve leaks, replace the valve, add

water and degas the circuit.

Anti-silt fi lter missing or clogged in the

brine water circuit’s backfl ow.

Install an anti-silt fi lter.

Clean the anti-silt fi lter.

The circuit was not properly bled

Activate the bleeding function and top up the glycol water if

necessary.

The expansion vessel is defective.

Check the pressure of the expansion vessel.

Reinfl ate the expansion vessel. Replace the expansion vessel.

26

Brine circuit return

temperature too high (>42°C

in heating and >34°C in

cooling).

La température du circuit pompe à

chaleur est trop élevée.

Vérifi ez le circuit pompe à chaleur et le circuit chaudière.

Il y a une mauvaise lecture de la

température.

Vérifi ez les connexions du capteur. Vérifi ez que la position et le

fonctionnement du capteur sont corrects.

Vérifi ez la résistance du capteur.

39

Waiting following pre-scan

of return temperature (<42°C

in heating and <34°C in

cooling).

Il y a une mauvaise indication du débit

d'eau.

Vérifi ez qu'il n'y a pas de débit d'eau en fermant une vanne sur le

circuit pompe à chaleur. Forcez la pompe et vérifi ez le débit.

32

Air temperature incompatible

with the start-up of heat

pump (between -7 and 25°C

in heating, and between 18

and 48°C in cooling).

The air temperature is too low or too

high.

Check the outside temperature.

Move the heat pump.

Incorrect temperature reading.

Check the sensor’s connections. Check that the position and the

operation of the sensor are correct.

Check the sensor’s resistance.

Status Description

39

Wait after pre-sweep of a return temperature (refer to the

following table for details of this status).

40

Flow rate fault (blocking fault after 3 attempts).

41

Compressor outlet temperature fault (> 105°C) (10min

temporary block).

42

De-icing request while reheating water tank.

43

In cooling mode, return temperature too high (> 47°C) (10

min temporary block)

16 Servicing

To ensure the continued effi cient and safe operation of the

appliance it is recommended that it is checked and serviced as

necessary at regular intervals. The frequency of servicing will

depend upon the particular installation conditions and usage.

• Servicing/maintenance should be carried out by a competent

person approved at the time by the Health and Safety

Executive in accordance with the rules in force in the

countries of destination.

• To obtain service, please call your installer or Glow-worm’s

own service organisation.

• After servicing, complete the relevant Service Interval

Record section of the Benchmark Checklist located on the

inside back pages of this document.