Installation, Maintenance, 15 trouble-shooting – Glow-worm Clearly Heat Pump 5 kW User Manual

Page 22

0020111744_00 - 09/10 - Glow-worm

- 20 -

INSTALLATION

MAINTENANCE

i

Any work carried out on the refrigerant circuit must

be conducted by qualifi ed engineers.

The faults described in this chapter require the services

of a qualifi ed professional and, if necessary, a Glow-worm

Groupservice engineer.

15 Trouble-shooting

15.1 Fault

diagnosis

The following checks should be performed before proceeding

onto specifi c diagnostics:

- Make sure that the electricity supply has not been interrupted

and that the appliance is connected correctly.

- Ensure that the isolating valves are open.

- Check that all external controls are connected correctly.

15.2 Fault

codes

i

The faults described in this chapter should be

carried out by a qualifi ed engineer or a Glow-worm

Groupservice engineer.

In this section, you will fi nd the fault codes that may appear and

the corrective actions you can take to return the appliance to

service.

In the case of a fault, the fault code number is displayed on the

control unit.

• Carry out any necessary repairs.

• Restart the heat pump using the ON / OFF button.

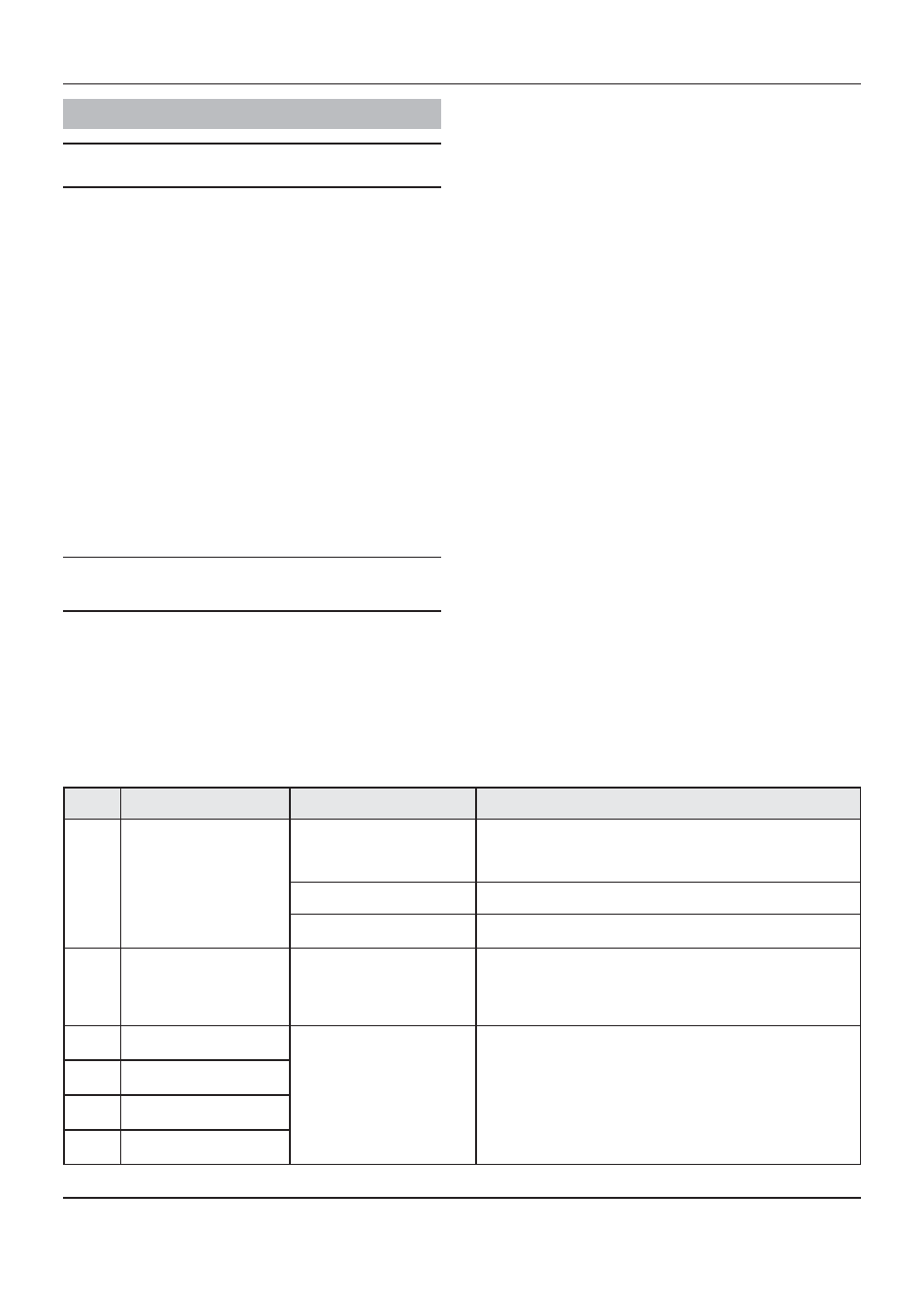

Fault

codes

Description

Cause

Solution

23

The temperature difference

between the output and the

return of the brine circuit is too

high (> 15K).

Non-blocking failure

Misreading of the circuit

temperature.

Check the plate to plate exchanger return and outgoing temperature

sensor connections. Check that the position and the operation of the

sensor are correct.

Add thermal grease.Check the sensor’s resistance.

The electronic circuit board is not

operating.

Replace the circuit board.

Faulty indication of water fl ow.

Check that there is no water fl ow by closing a valve in the brine circuit.

Force the pump and check the fl ow.

37

The fan speed is too low.

(<300 rpm)

Blocking failure if produced

more than 3 times in the last

10 starts.

The fan speed is too low.

Check the fan connections.

Check the fuses in the main PCB.

Change the electrical panel.

Check the space in front of the fan grill.

Replace the fan motor.

514

Compressor suction

temperature sensor failure.

The sensor is defective or is not

correctly connected to the main

PCB.

Check the sensor’s connections.

Check that the position and the operation of the sensor are correct.

Check the sensor’s resistance.

517

Compressor discharge

temperature sensor failure.

519

Brine circuit return temperature

sensor failure.

520

Brine circuit output

temperature sensor failure.