Maintenance, 17 trouble-shooting – Glow-worm Clearly Heat Pumps 14kW User Manual

Page 37

0020117819_01 - 05/11 - Glow-worm

- 35 -

MAINTENANCE

i

Any work carried out on the refrigerant circuit must be

conducted by qualifi ed engineers.

The faults described in this chapter require the services

of a qualifi ed professional and, if necessary, a Glow-worm

Groupservice engineer.

17 Trouble-shooting

17.1 Fault

diagnosis

The following checks should be performed before proceeding

onto specifi c diagnostics:

•

Make sure that the electricity supply has not been interrupted

and that the appliance is connected correctly.

•

Ensure that the isolating valves are open.

•

Check that all external controls are connected correctly.

17.2 Fault

codes

i

The faults described in this chapter should be

carried out by a qualifi ed engineer or a Glow-worm

Groupservice engineer.

17.2.1

Fault codes accessible from the install menu

When the symbol “a” blinks at the bottom left of the control box,

the appliance has a fault. You should access parameters 22 (last

fault code) and 23 (history of last 4 faults) on the installer menu.

•

Simultaneously press the (

) and (

) buttons for 3

seconds, the parameter number is displayed and its value

blinks.

•

Press the buttons (

) until parameter 22 or 23 is displayed.

•

Press the (M) button to access the parameter, the value of the

parameter blinks.

•

Press the (

) buttons to modify the value.

•

Press the (M) button to confi rm the parameter setting.

•

Press the (OK) button to exit the menu and confi rm the settings.

•

Refer to the “Hydraulic and refrigerant schematic” chapter to

identify the sensor positions.

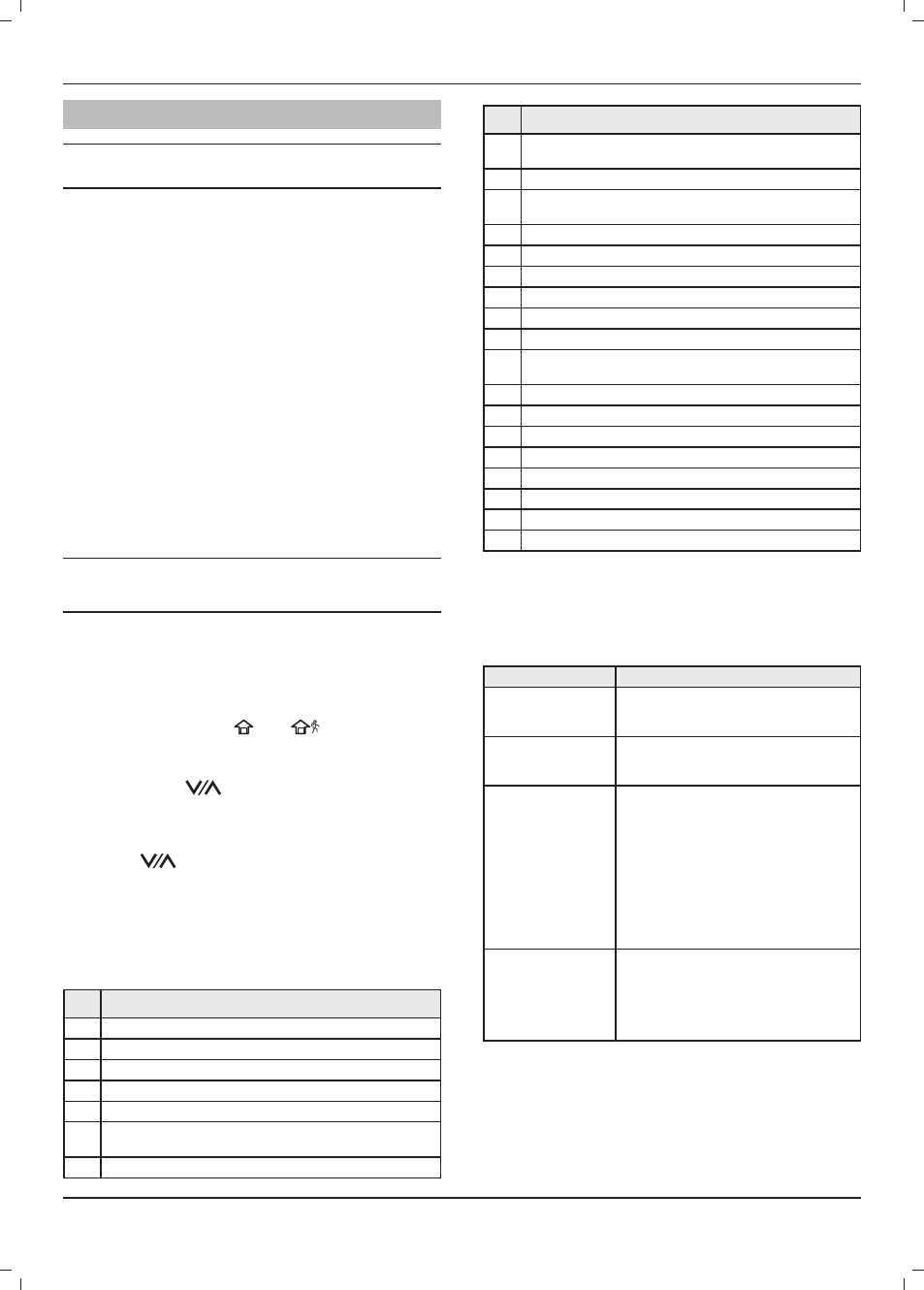

Code Description

3

Heat pump return temperature sensor fault (n°15)

4

Pre-regulator temperature sensor fault (n°18)

5

Remote outside air temperature sensor fault

6

Loss of communication with the command unit

7

Control box ambient air temperature sensor fault

8

Power matching fault between the electronic control circuit board

and the appliance

9

Water fl ow rate (n°10) or circulator pump (n°11) sensor fault

Code Description

10 Outside air temperature greater than the maximum in heating

(parameter 119)

11 Air temperature higher than the maximum value for heating

12 Outside air temperature greater than the maximum in cooling

(parameter 123)

14 Loss of compressor signal

15 Heat pump outlet temperature sensor fault (n°14)

17 Outside air temperature sensor fault (n°2)

18 Protection against short-circuits in G-Tr variator

20 Error in controlling the position of the compressor rotor

21 Error in current variator sensor

22 Fin exchanger (n°4) or compressor intake (n°6) temperature

sensor fault

23 Compressor outlet temperature sensor fault (n°23)

24 Outside fan fault

26 Other outside faults

27 Compressor blocked

28 Compressor outlet temperature error

29 Compressor breakdown

30 Low pressure switch

31 Over-pressure valve

17.2.2 Specifi c faults shown on the control box main

screen

The faults listed below are identifi ed directly on the control box

main screen.

Fault

Description

Control box ambient

temperature sensor

fault

In the case of an anomaly in the temperature

sensor measurement, the temperature

display is replaced by “--“.

Control box ambient

humidity sensor fault

In the case of an anomaly in the humidity

sensor measurement, the ambient humidity

display is replaced by “--“.

Control box EEPROM

fault

If the control box non-volatile memory

(EEPROM) is defective, the code “E4” is

displayed in the control box temperature

display area. If the power is cut after this

fault is displayed, the installer and after-

sales parameters will be restored to their

default values and the installation-specifi c

parameters will be erased. This fault can

result in poor operation of the installation. In

the case of an “E4” fault, replace the control

box.

Communications fault

If communication between the control box

and the heat pump control circuit board

is disturbed, error “E3” is displayed in

the ambient temperature display area. In

this case, check the communication cable

between the control box and the heat pump.

MAINTENANCE