Installation, 11 hydraulic connection, 12 discharge of condensate – Glow-worm Clearly Heat Pumps 14kW User Manual

Page 24: 13 electrical connection

0020117819_01 - 05/11 - Glow-worm

- 22 -

11 Hydraulic connection

•

Take care to clean the pipes before assembly removing any

debris or burrs. Grease and oils may need to be removed they

are not possible to remove by cleansing and fl ushing. Foreign

bodies in the system may enter the appliance and interrupt its

operation.

•

Do not use any solvent products, due to the risk of damaging

the circuit.

•

Only use original seals supplied with the appliance.

b

Make sure that mechanical connections are not

overtightened.

b

Insulate the pipes (between the heat pump and the

installation including those underground) with an UV-

and high-temperature-resistant insulation.

1m min.

1

2

3

7

4

4

5

6

8

key

1 Heat

pump

fl ow circuit ¼ turn shut-off valve in the direction of the

building (not included) (*)

2 Return circuit ¼ turn shut-off valve in the direction of the heat pump

(not included) (*)

3 Return circuit hose in the direction of the heat pump (not supplied)

4 Cap

5 Return connection (Ø1 ") to the heat pump

6 Flow heat pump connection (Ø1 ") to the building

7 Flow heat pump circuit hose in the direction of the building (not

supplied))

8 Insulation (not supplied)

(*) To be installed as close as possible to the heat pump

•

Remove the protection caps (4) located on the connections.

•

Comply with the values given in the table below when making

the hydraulic connections of the heat pump circuit.

Max linear distance (without elbows or

additional pressure drops)

Tubes to be installed

≤ 20 m

¾" or Ø internal = 20 mm

≤ 30 m

1" or Ø internal = 26 mm

•

Connect a hose and a shut-off valve to the return connection to

the heat pump.

•

Connect a hose and a shut-off valve to the fl ow heat pump

connection in the direction of the building.

•

Install the fi lter on the heat pump return pipe. Install it

between 2 shut-off valves in order to be able to remove if from

the circuit and clean it periodically.

•

Insulate all exposed pipework.

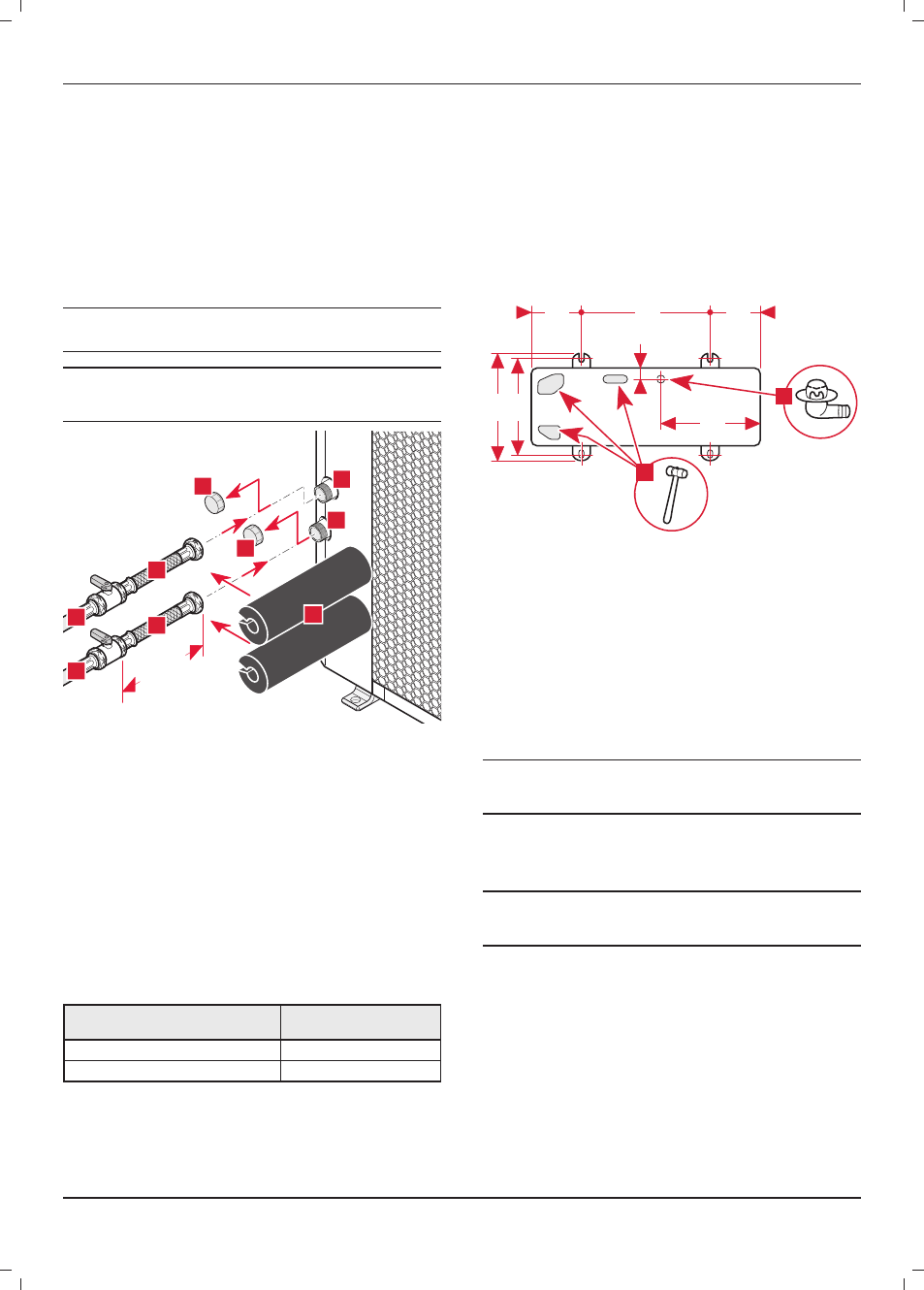

12 Discharge of condensate

When the appliance is operational, it will produce condensation

that needs to be drained off .

1

2

600

150

150

430

400

363

37

Key

1 Evacuation bend for condensates

2 Holes pre-cut in the base of the heat pump

•

Install the bend (1) delivered with the appliance and connect it

to an evacuation pipe with an internal diameter of 16 mm (not

supplied).

•

Make sure that the condensates evacuation pipe does not

freeze.

The discharge capacity of the condensate increases if the pre-cut

holes (2) present in the base are open. Open the pre-cut holes

using a hammer.

i

If you choose to open the pre-cut holes (2) present in

the base, take the necessary precautions to recover

the condensates and stop them freezing.

13 Electrical connection

e

Incorrect installation can cause electric shock or

appliance damage. The electrical connection of the

appliance must be made only by a qualifi ed engineer.

The appliance must be connected directly to an accessible, fi xed,

switched, electrical outlet.

The manufacturer declines any responsibility for damages to

persons or others caused by the incorrect installation of the

appliance earthing. This includes failure to comply with current

standards.

Electrical components have been tested to meet the equivalent

requirements of BSEN 7671 and the BEAB regulations.

The cables connecting the installation's electrical panel and the

heat pump must be:

- Suitable for a fi xed installation.

INSTALLATION