E-Tech Series EGT EGF User Manual

Page 15

Page 15 / 80

ED, EG Rev. 2 - Operating Instructions

GB

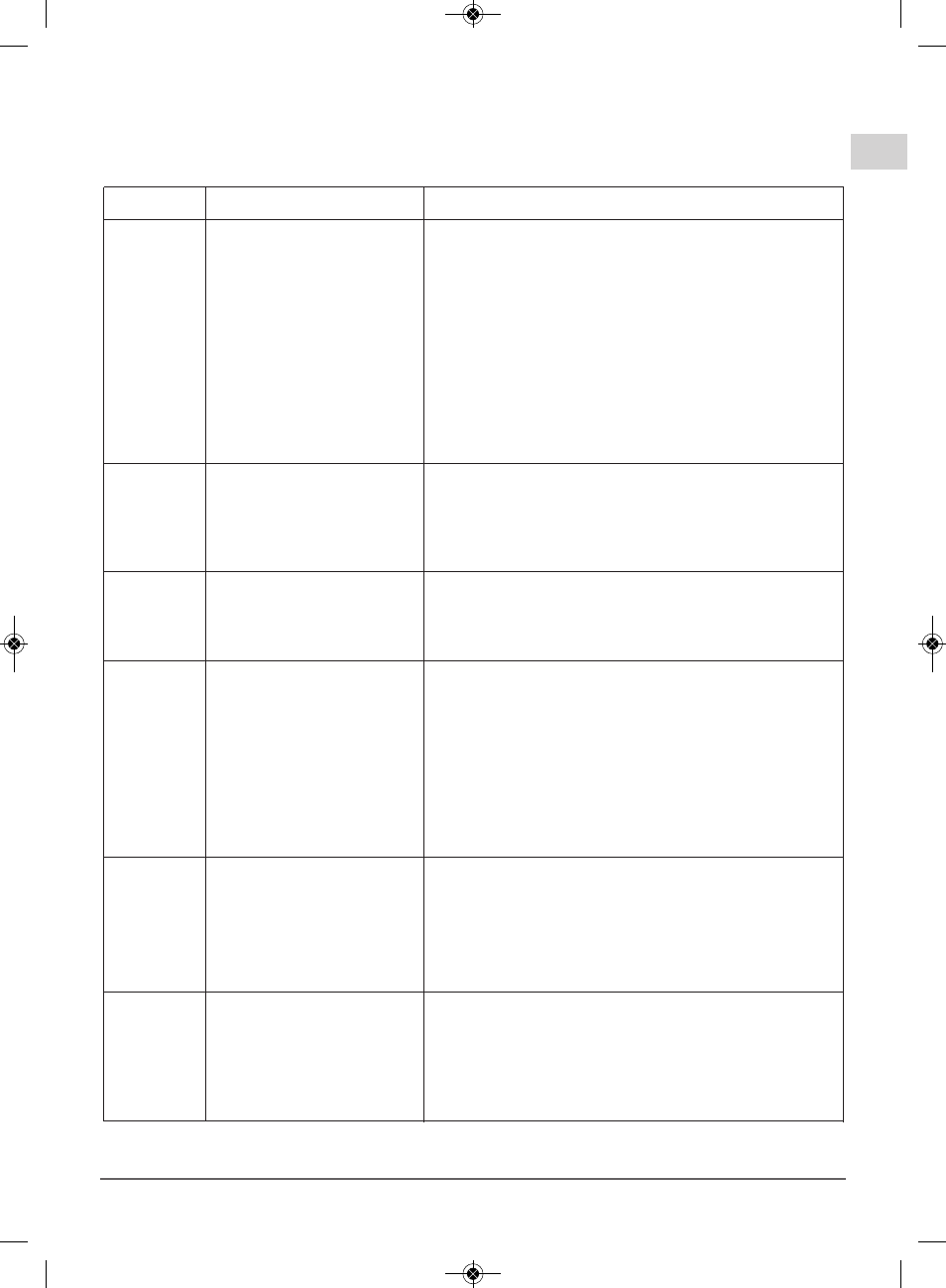

PROBLEM

1) The engine

does not

start

2) Pump

blocked

3)The pump

functions

but no water

comes out

4) Insufficient

flow

5) Noise and

vibrations

from the

pump

6) Leakage

from the

mechanical

seal

PROBABLE CAUSES

1a) Unsuitable power supply

1b) Incorrect

electrical

connections

1c) Engine overload protective

device cuts in.

1d) Blown or defective fuses

1e) Shaft blocked

1f) If the above causes have

already been checked, the

engine may be malfunctioning

2a) Presence of solid bodies in

the pump rotor

2b) Bearings blocked

3a) Presence of air inside the

pump or suction tube

3b) Suction filter blocked

4a) Pipes and accessories with

diameter too small causing

excessive loss of head

4b) Presence of deposits or solid

bodies in the internal passages

of the rotor suction filter

4c) Rotor deteriorated

4d) Worn rotor and pump case

4e) Excessive viscosity of the liquid

pumped (if other than water)

4f) Incorrect direction of rotation

5a) Rotating part unbalanced

5b) Worn bearings

5c) Pump and pipes not firmly

attached

5d) Flow too strong for the

diameter of the delivery pipe

5e) Unbalanced power supply

6a) The mechanical seal has

functioned when dry or has

stuck

6b) Mechanical seal scored by

presence of abrasive parts in

the liquid pumped

11. Troubleshooting

WARNING: Turn off the power supply before performing any operations.

Do not allow the pump or motor to run when dry even for a short period

Strictly follow the user instructions and if necessary contact an authorised service centre

POSSIBLE REMEDIES

1a) Check that the mains frequency and voltage correspond to the

electrical characteristics shown on the indicator plate

1b) Connect the power supply cable to the terminal board correctly.

Check that the thermal overload protection is set correctly (see

data on the engine indicator plate) and make sure that the

fuseboard upline of the engine has been properly connected

1c) Check the power supply and make sure that the pump shaft is

turning freely. Check that the thermal overload protection has

been set correctly (see engine indicator plate)

1d) Replace the fuses, check the electric power supply and points

a) and c)

1e) Remove the cause of blockage as indicated in the “Blocked pump”

instruction booklet

1f) Repair or replace the engine by applying to an authorised

service centre

2a) If possible, dismantle the pump casing and remove any solid

foreign bodies inside the rotor, if necessary contact an

authorised service centre

2b) If the bearings are damaged replace them or if necessary

contact an authorised service centre

3a) Release the air from the pump using the pump plugs and/or

using the delivery control valve .Repeat the filling operations

until all air has been expelled

3b) Clean the filter, if necessary, replace it . See point 2b) also.

4a) Use pipes and accessories suitable for the specific application

4b) Clean the rotor and install a suction filter to prevent other

foreign bodies from entering

4c) Replace the rotor, if necessary, contact an authorised service

centre

4d) Replace the rotor and the pump casing

4e) The pump is unsuitable

4f) Invert the electrical connections on the terminal board or control

panel

5a) Check that no solid bodies are obstructing the rotor

5b) Replace the bearings

5c) Anchor the delivery and suction piping as needed

5d) Use bigger diameters or reduce the pump flow

5e) Check that the mains voltage is right

In cases 6a), 6b), replace the seal, if necessary contact an

authorised service centre

6a) Make sure that the pump casing is full of liquid and that all the air

has been expelled.

6b) Use a seal suited to the characteristics of the liquid being pumped.

Changes reserved.

IST ED_ED_04_2015:MXS 11_03con gall 14/04/15 17:45 Pagina 15