0 maintenance – ENMET MX-52 User Manual

Page 35

MX52 C

ONTROL

ENMET Corporation

31

6.0 Maintenance

6.0 Maintenance

6.0 Maintenance

6.0 Maintenance

W

ARNING

:

The handling operations and adjustments described in this section must be performed by authorized

personnel, as they affect detection safety.

6.1 Periodic / Preventive Maintenance

6.1.1 On the

MX52 C

ONTROL

The

MX52 C

ONTROL

requires a small amount of maintenance. However, it is recommended that the test functions

available on the

MX52 C

ONTROL

unit be used to regularly test the essential functions of the control.

Check the functions of the control as follows:

Use the TEST switch to check the correct operation of all the LEDs and the buzzer.

Use the “SIMULATION” menu to check the correct operation of the display panel, the triggering of alarms

(LED and relays), the auxiliary devices and the 4-20 mA current output.

Cause a fault to occur (such as a line fault by disconnecting a detector wire) to check the correct operation of

the fault indications.

6.1.2 On the Sensor/Transmitters

Sensor/transmitters must be calibrated periodically according to instructions furnished with those units.

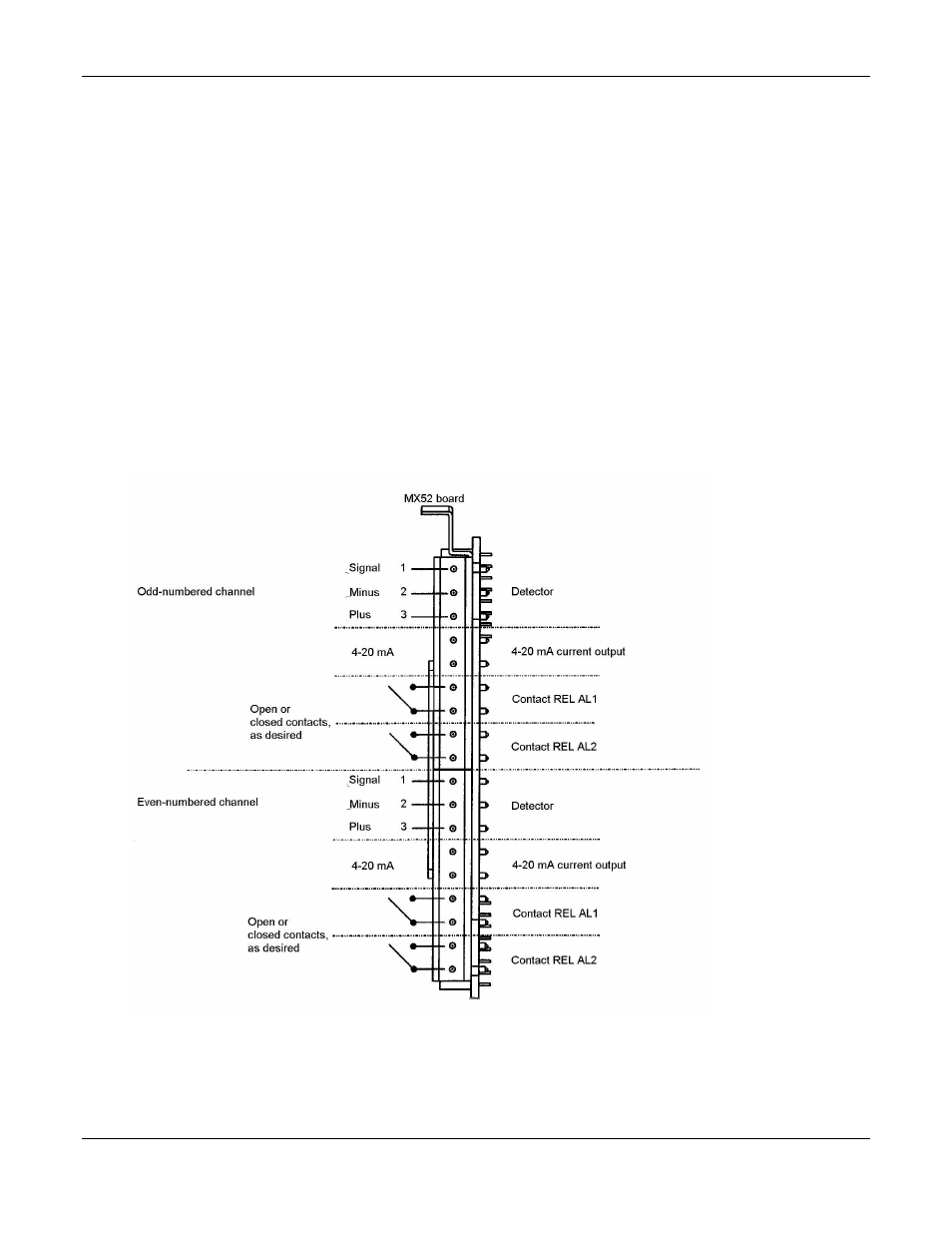

Figure 12: Channel Board, Outputs on Rear Connector

+

+

+

+

–

–

–

–

+

+

+

+

–

–

–

–