Delta Electronics SIQ126R User Manual

Smt power inductor, Siq126r type, Electrical characteristics

o

25 C, 100KHz, 0.1V

SMT Power Inductor

SIQ126R Type

34

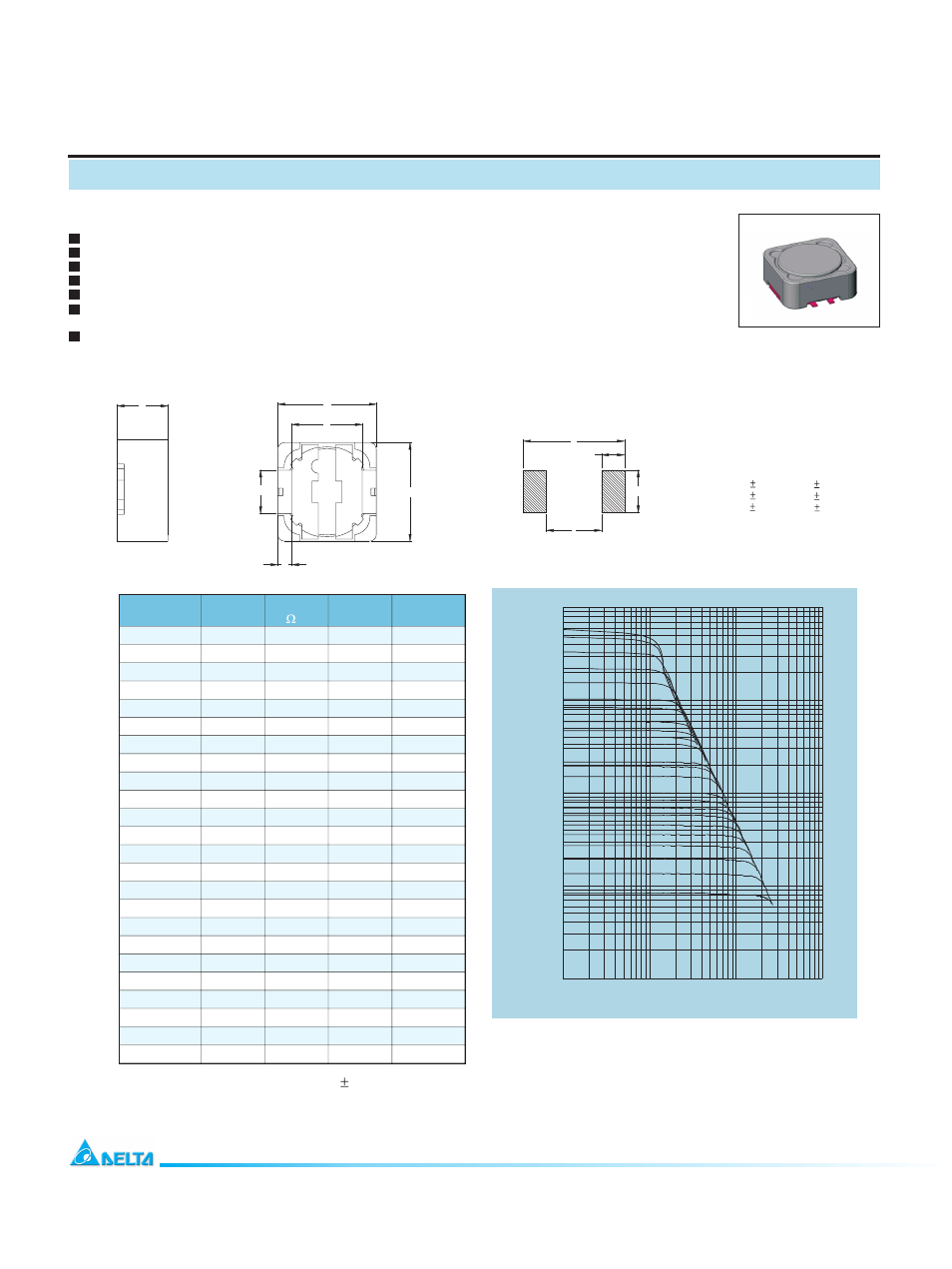

Electrical Characteristics:

DELTA ELECTRONICS, INC.

(TAOYUAN PLANT CPBG)

252, SAN YING ROAD, KUEISAN INDUSTRIAL ZONE, TAOYUAN SHIEN, 333, TAIWAN, R.O.C.

TEL: 886-3-3591968; FAX: 886-3-3591991

http://www.deltaww.com

Irms

(Adc)

3

Isat

(Adc) Max.

2

L

(uH)

1

PART NO.

DCR

(m ) Max.

SIQ126R - 0R8

0.8

5.0

22.00

22.00

SIQ126R - 1R3

1.3

6.0

18.00

18.00

SIQ126R - 2R0

2.0

7.0

15.00

15.00

SIQ126R - 2R7

2.7

8.0

13.00

13.00

SIQ126R - 3R5

3.5

9.0

11.00

11.00

SIQ126R - 4R5

4.5

11.0

10.00

10.00

SIQ126R - 5R7

5.7

13.0

9.00

9.00

SIQ126R - 6R8

6.8

16.0

8.00

8.00

SIQ126R - 8R2

8.2

17.0

7.50

7.50

SIQ126R - 100

10.0

21.0

6.50

6.50

SIQ126R - 150

15.0

30.0

5.60

5.60

SIQ126R - 180

18.0

36.0

5.00

5.00

SIQ126R - 220

22.0

41.0

4.50

4.50

SIQ126R - 330

33.0

54.0

3.60

3.60

SIQ126R - 390

39.0

66.0

3.30

3.30

SIQ126R - 470

47.0

80.0

3.20

3.20

SIQ126R - 560

56.0

100.0

2.80

2.80

SIQ126R - 820

82.0

140.0

2.40

2.40

SIQ126R - 101

100.0

180.0

2.00

2.00

SIQ126R - 151

150.0

250.0

1.60

1.60

SIQ126R - 221

220.0

340.0

1.40

1.40

SIQ126R - 331

330.0

500.0

1.15

1.15

SIQ126R - 471

470.0

750.0

0.95

0.95

SIQ126R - 561

560.0

880.0

0.88

0.88

1. Tolerance of inductance : 0.8~560uH 20

%.

2. Irated is the DC current which cause the inductance drop less than 30% of its nominal inductance without current

o

and the surface temperature of the part increase less than 45 C.

o

o

3. Operating temperature: -20 C to 105 C (including self-temperature rise).

RoHS compliant.

Low profile (7.0mm max. height ), high current(22A, 0.8uH) SMD type.

Magnetically shielded, suitable for high density mounting.

High energy storage and low DCR.

Provided with embossed carrier tape packing.

Ideal for power source circuits, DC-DC converter, DC-AC inverters

inductor applications.

In addition to the standard versions shown here,

customized inductors are available to meet your exact requirements.

Features

Mechanical Dimension:

UNIT : mm/inch

A = 12.5 / 0.492 MAX.

B = 7.0 / 0.276 MAX.

D = 7.6 0.3 / 0.299 0.012

E = 5.0 0.2 / 0.197 0.008

C = 12.5 / 0.492 MAX.

F = 2.2 0.2 / 0.087 0.008

G = 5.4 / 0.213

H = 2.9 / 0.114

I = 7.0 / 0.276

J = 12.8 / 0.504

RECOMMENDED PAD PATTERNS

B

C

H

G

I

D

F

E

A

J

0R8

1R3

2R0

2R7

3R5

4R5

5R7

6R8

8R2

100

150

180

220

330

390

470

560

820

101

151

221

331

471

561

0

1

10

100

1000

0

1

10

100

DC BAIS(A)

IN

D

U

C

T

A

N

C

E

(u

H

)