Trouble shooting guide – Bolens 300 Series User Manual

Page 19

Attention! The text in this document has been recognized automatically. To view the original document, you can use the "Original mode".

TROUBLE SHOOTING GUIDE

TROUBLE

LOOK FOR

REMEDY

Engine will not

crank

Battery installed incor

rectly

The battery must be installed with the negative terminal, identified at the terminal post by (Neg, N

or -), grounded. The positive terminal (Pos, P or +) attaches to the large cable from the solenoid.

The small red wire from the fuse holder or circuit breaker is also attached to the positive terminal.

Blown fuse or circuit

breaker

Replace fuse with

IVz

amp. fuse V4 x 1V4" Ig. Circuit breaker will reset itself when it cools off. Fuses

or circuit breakers seldom open or fail without a reason. The problem must be corrected. Check for

loose connections in the fuse holder. Replace fuse holder if necessary. A dead short may be in the

cranking or charging circuit where the insulation may have rubbed through and exposed the bare

wire. Replace the wire or repair with electrician’s tape if the wire strands have not been damaged.

Note: Look for a wire pinched between body panels, burned by the exhaust pipe or muffler or rubbed

against a moving part.

Battery is dead or weak

Use a hydrometer to check the condition of the battery. The Specific Gravity (s.g.) should be 1.265

at 80°F. (1.215 s.g. minimum needed for cranking engine). The reason for the battery failing must

be determined. (1) Defective battery. Battery will not accept or hold a full charge. (2) Short circuit.

Check for grounded wire. (3) Charging system not working.

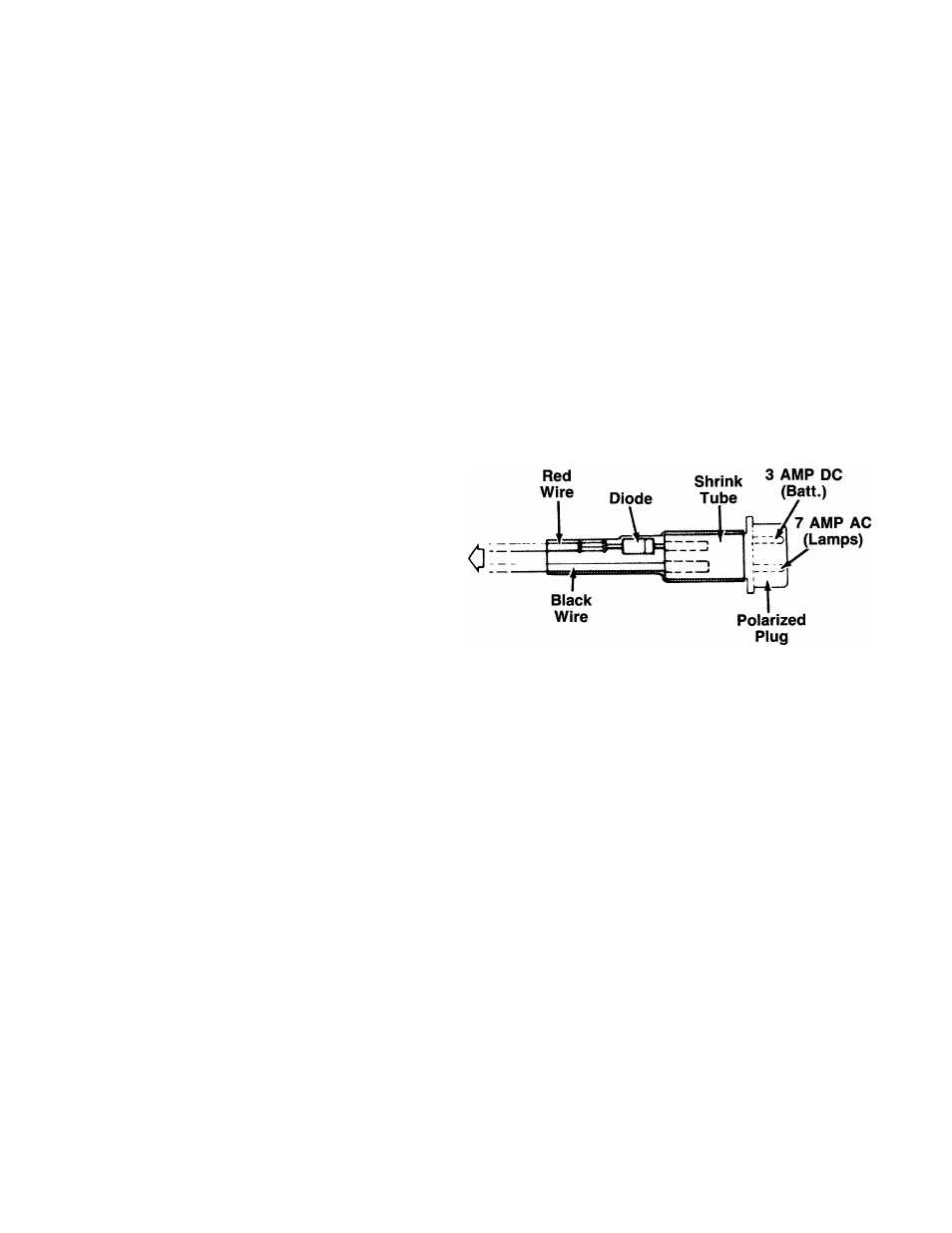

The charging system is an alternator located under the flywheel. It is unregulated and rated 3 amp.

at 3600 r.p.m. A diode (rectifier) is located in the output lead just before the wire harness plug on

the engine side.

To Alternator

The diode changes A.C. to D.C. to charge the battery. A bad diode can either fail to charge the bat

tery or discharge the battery if the alternator is shorted as well as the diode. To test: (1) Disconnect

charger lead from the battery (small red wire). (2) Connect 12 V small test lamp between the 3 amp.

D.C. charge lead and the positive terminal of the battery. (3) With the engine off, the lamp should

not light. If it does, the diode and possibly the alternator should be replaced. (4) Start the engine.

The lamp should light. If it does not, the alternator (stator) or lead wire is bad and should be replaced.

Mechanical failure

(Wires and switches)

The interlock system includes two mechanical activated switches which are wired in series in the

circuit used to energize the starter solenoid. While testing the interlock system, you will make the

mower temporarily unsafe by permitting the engine to be started with the blade and clutch engaged.

WARNING: While testing, disengage the clutch, shut off the blade control, set the parking brake and

place the gear shift lever in neutral. Attach a wire (minimum 18 gauge) to the positive terminal of the

battery and touch the other end to the small terminal on the solenoid. If the engine does not crank: (1)

There is a loose connection or poor ground. (2) The solenoid may be bad. The solenoid can be checked

by using a heavy wire (#8 gauge minimum) and jumping between the two large terminals. If the engine

cranks, the solenoid is bad. (3) If the engine does not crank when you jump the solenoid, have the

starter motor tested by an authorized engine dealer. If the engine does crank, the problem is with

one of the safety switches, ignition switch or the wire between the fuse holder (or circuit breaker) and

the small terminal on the solenoid. Note: Look for a poor connection at the switches or a defective

switch. Replace if necessary.

Engine cranks

but will not start

Throttle or choke not in

starting position

Check owner’s guide for correct position for throttle control and choke for starting.

No spark to spark plug

Spark plug lead disconnected. Connect lead. Hold spark plug lead away from engine block about

1/8". Crank engine. There should be a spark. If not, have engine repaired at authorized engine ser

vice dealer.

Faulty spark plug. To test, remove spark plug. Attach spark plug lead to spark plug. Ground the spark

plug body against the engine block. Crank the engine. The spark plug should fire at the electrode.

Replace if it does not.

19

“