Lubrication, Steering gears, Steering shaft – Bolens 300 Series User Manual

Page 15: Transaxle, Wheels, Pivot points, Maintenance, Trouble shooting, Engine, Cutting blade

Attention! The text in this document has been recognized automatically. To view the original document, you can use the "Original mode".

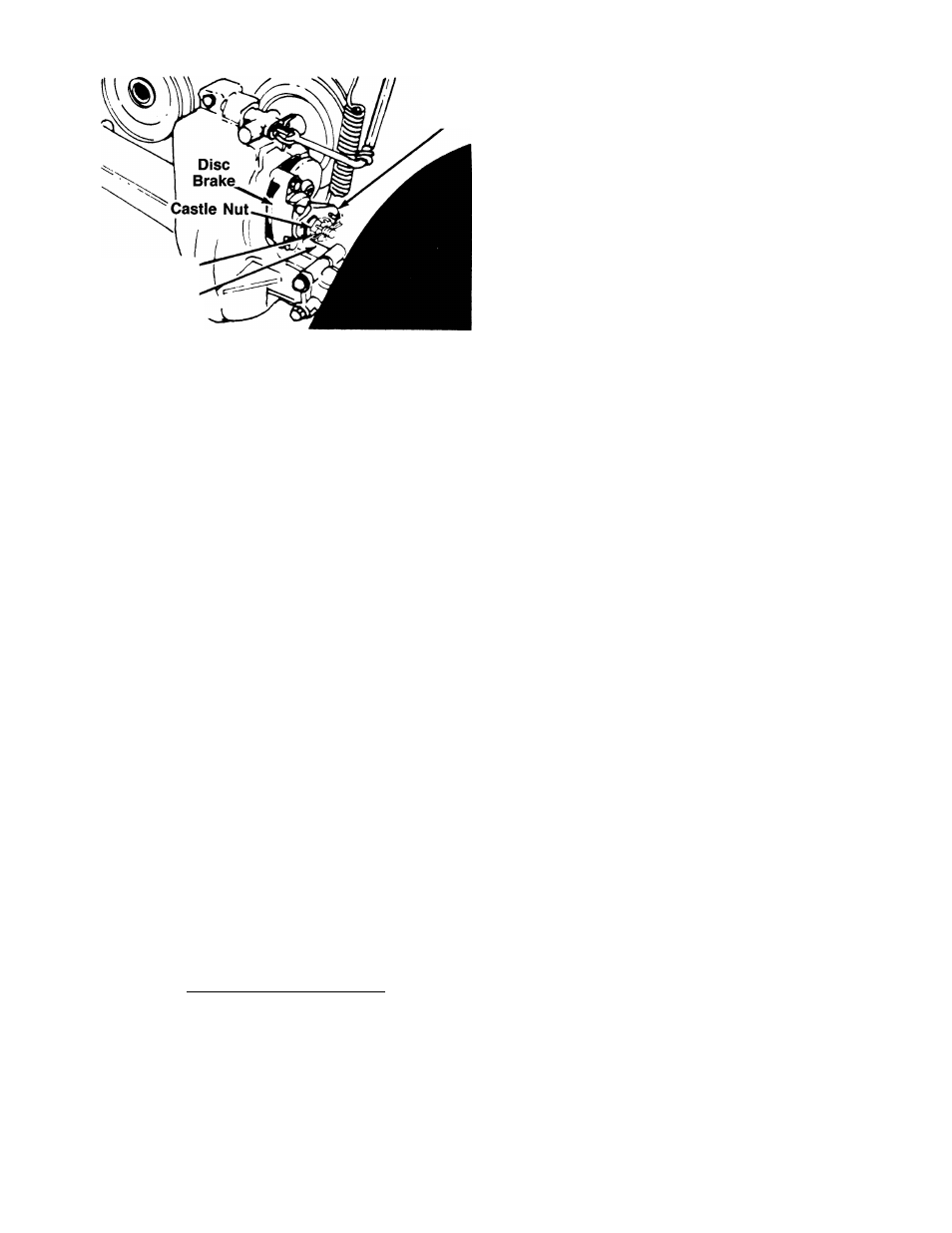

Brake

Lever

Cotter Pin

Axle^

Housing

FIGURE 19.

LUBRICATION

▲

WARNING:

Always

stop

engine

and

disconnect spark plug wire before clean

ing, lubricating or doing any kind of work

on lawn tractor.

STEERING GEARS

Lubricate teeth of steering gears with automotive multi

purpose grease after every 25 hours of operation or

once a season.

STEERING SHAFT

Lubricate steering shaft at least once a season with light

oil.

TRANSAXLE

The transaxle is lubricated and sealed at the factory

and does not require checking. If disassembled for any

reason, lubricate with 10 oz. of grease, part number

737-0148.

WHEELS

The front wheels are provided with grease fittings. The

rear wheels must be removed from the axle for lubrica

tion. Lubricate both front and rear wheels at least once

a season with automotive multi-purpose grease.

PIVOT POINTS

Lubricate all pivot points with light oil at least once a

season.

A

MAINTENANCE

WARNING: Disconnect the spark plug wire

and ground against the engine before per

forming any repairs or maintenance.

TROUBLE SHOOTING

Refer to page 19 of this manual for trouble shooting

information.

ENGINE

Refer to the separate engine manuai for engine

maintenance instructions.

Maintain

engine oii as instructed in the separate

engine manual packed with your unit. Read and follow

instructions carefully.

Service

air cleaner every 10 hours under normal con

ditions. Clean every few hours under extremely dusty

conditions. Poor engine performance and flooding

usually indicates that the air cleaner should be

serviced. To service the air cleaner, refer to the

separate engine manual packed with your unit.

The

spark plug should be cleaned and the gap reset

once a season. Spark plug replacement is recom

mended at the start of each mowing season; check

engine manual for correct plug type and gap

specifications.

CUTTING BLADE

A. Removal for Sharpening or Repiacement

A

WARNING: Be sure to disconnect and

ground the spark piug wire and remove ig

nition key before working on the cutting

biade to prevent accidentai engine start

ing. Protect hands by using heavy gioves

or a rag to grasp the cutting biades.

1. Remove the large bolt and lock washer which holds

the blade and adapter to the blade spindle.

2. Remove the blade and adapter from the spindle.

3. If the blade or blade adapter needs replacing,

remove the two small bolts, lock washers and nuts

which hold the blade to the adapter.

B. Sharpening

Remove the cutting blade by following the directions

of the preceding section.

When sharpening the blade, follow the original angle

of grind as a guide. It is

extremely important that each

cutting edge receives an equal amount of grinding to

prevent an unbalanced blade. An unbalanced blade will

cause excessive vibration when rotating at high speeds,

may cause damage to the mower and could break,

causing personal injury.

The blade can be tested for balance by balancing it on

a round shaft screwdriver. Remove metal from the

heavy side until it balances evenly.

NOTE: It is recommended that the blade always be

removed from the adapter for the best test of balance.

C.

Reassembly

Before reassembling the blade and the blade adapter

to the unit, lubricate the spindle and the inner surface

15