Neutral adjustment (wheel drive), Cutting deck engagement adjustment – Bolens 300 Series User Manual

Page 13

Attention! The text in this document has been recognized automatically. To view the original document, you can use the "Original mode".

'N.

b.

5-speed units: Place speed control lever in first

position.

13. Place ferrule into speed control lever slot, and

secure with flat washer and hairpin clip. Release

the clutch-brake pedal.

Speed

.Control Hairpin Clip

n

Lever and Flat Washer

‘ '

:/

Neutral

Slot

-, V' '

Slot Clutch-Brake

Pedal

Ferrule

Variable

Speed Speed

Bracket Control

Link

Hairpin Clip

and Flat Washer

FIGURE 14.

Next, adjust the speed control link as follows to obtain

the correct neutral adjustment.

1. Push the clutch-brake pedal backward by hand as

far as it will go using light pressure. Hold it in this

position as you make the following adjustment.

2. Thread the speed control link into or out of the fer

rule until the eyelet on the opposite end of the link

slips onto the stud on the bottom side of the

variable speed bracket.

3. Secure the speed control link to the variable speed

bracket with flat washer and hairpin clip.

NEUTRAL ADJUSTMENT (Wheel Drive)

1. Place the transmission in neutral. (The unit will

move freely when pushed forward and backward

with the parking brake released.)

2. Loosen the bolt which secures the shift lever

assembly to the shift lever adjusting link. See figure

15.

3. Place the shift lever in the netural slot. See figure

15.

4. Tighten the bolt to 13 foot pounds.

Shift

Lever

Loosen

Hex Bolt

FIGURE 15.

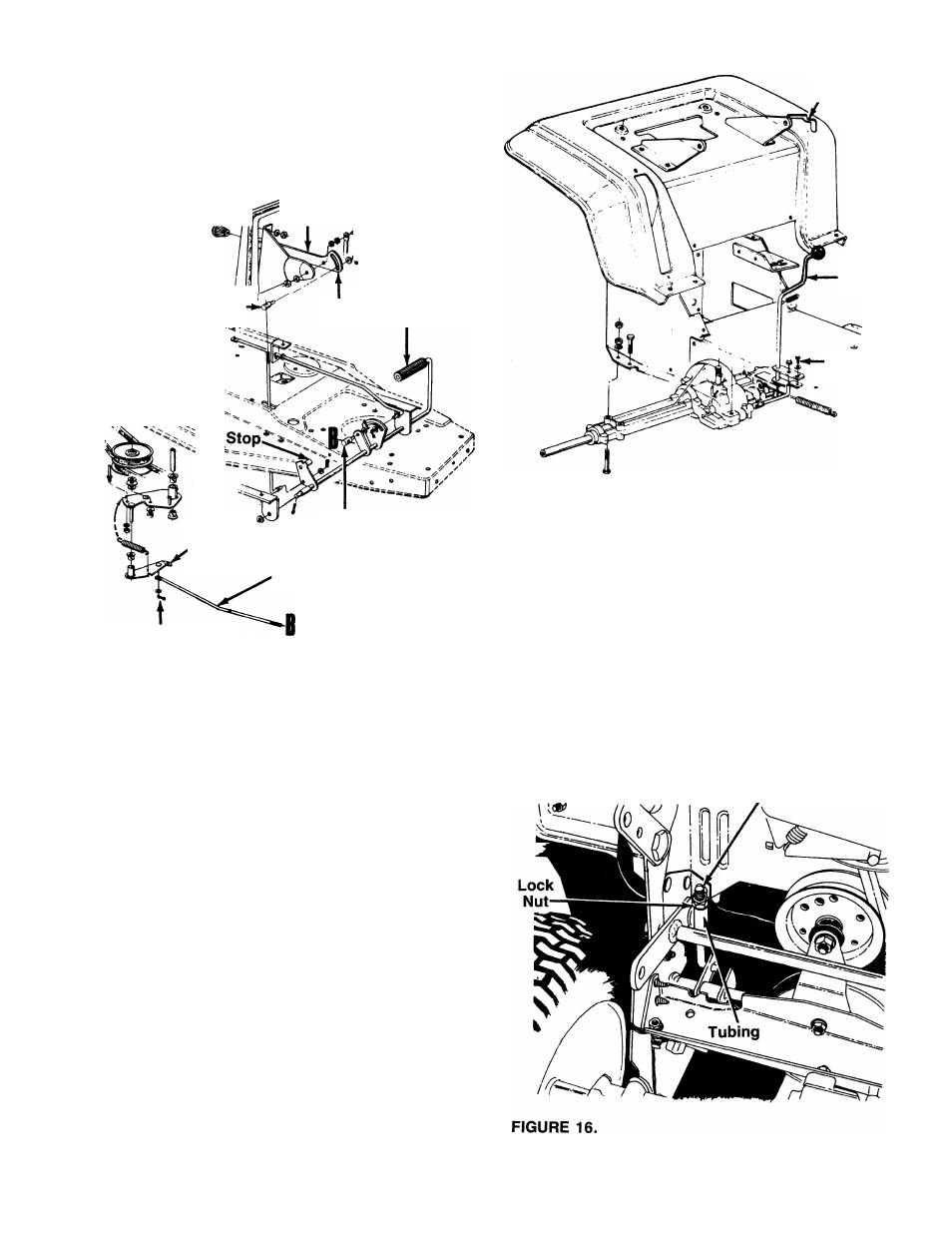

CUTTING DECK ENGAGEMENT ADJUSTMENT

The cutting deck engagement may be adjusted to make

certain deck is disengaged when lift and disengage

ment lever is in the disengaged position, or to obtain

more drive in the cutting positions. Correct adjustment

as follows.

Place the lift and disengagement lever in the highest

cutting position (first notch down from disengaged posi

tion). The approximate adjustment is to have the lock

nut on the threaded rod (above the rear of the deck)

touching the end of the tubing. See figure 16.

Threaded

Rod

13