Sequence of operation—heating, Sequence of operation—cooling, Ímüwu – Bryant 394B User Manual

Page 6

Attention! The text in this document has been recognized automatically. To view the original document, you can use the "Original mode".

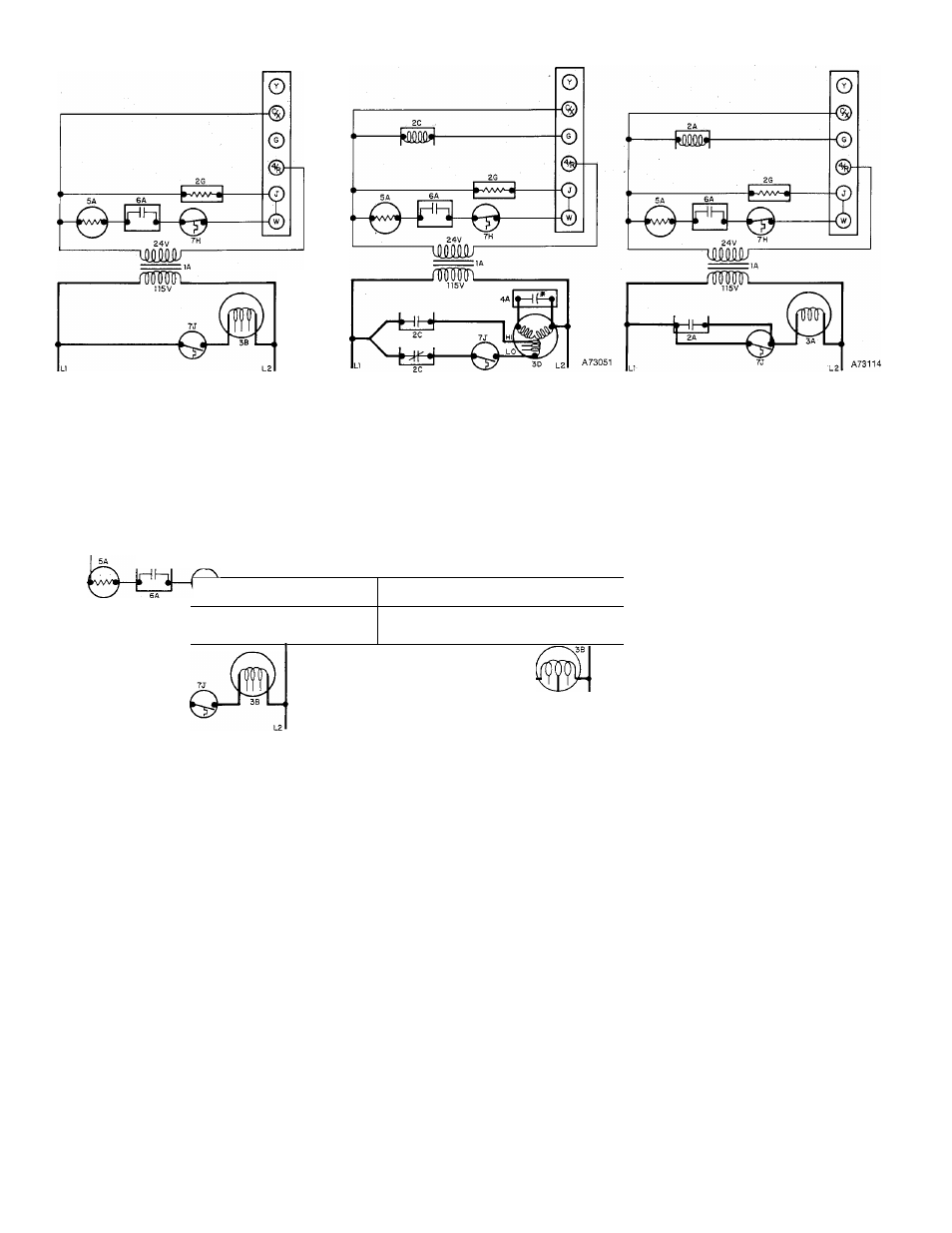

LINE-TO-LINE WIRING DIAGRAMS

Figure 9 - Units with 1/10-, 1/6-, or 1/5-KP Direct-

Drive Motor (no cooling fan relay)

Figure 10 - Units with 1/6-, 1/3-, 1/2-, or 3/4-HP

Direct-Drive Motor (cooling fan relay).

No Capacitor on 1/6- and 1/3-HP

Motors.

—Mna4----------------------

JE.

JiL

Figure 11 - Units with 3/4-HP Belt-Drive Motor

(cooling fan relay)

LEGEND

1 A-Transformer

2A-Cooling Fan Relay

2C-Cooling Fan Relay

2G-Fleatlng Fan Relay

3A-Fan Motor SP PH

3B-Fan Motor SP

3D-Fan Motor PSC

j

WM

H 5 V

R

2 4 V

___ a

4A-Capacitor (None on 1/6-

& 1/3-HP Motors)

l A

____

________________________

íMüWu

_________

5A-Gas Valve

6A-Pllot (None on LP)

/

A73053

■fciti-

fepi—©■

7J-Fan Control SPST N.O.

If any of the original wire, as supplied, must be

replaced, use same type or equivalent wire.

Figure 12 - 50,000-Btuh Unit with B or D controls

(no cooling fan relay)

Figure 13 - 50,000-Btuh Unit with B or D Controls

(cooling fan relay)

SEQUENCE OF OPERATION—HEATING

The pilot (6A) must be lit, closing its contacts, before

the gas valve (5A) will open. If, for some reason, the

gas valve does not open when thermostat calls for

heat, heat assist coil (2G) causes heating relay (7J) to

close its contacts, energizing blower motor (3A, 3B, or

3D).

When the thermostat calls for heat, the control circuit

is closed between terminals (4 and W). Power from

transformer (lA) energizes automatic gas valve coil

(5A) and heat assist coil (2G) simultaneously. After a

short time delay, automatic gas valve (5A) opens, per

mitting gas to flow to the burners where it is ignited

by the gas pilot. After another delay, the heating relay

switches its contacts (7J), energizing blower motor

(3A, 3B, or 3D) on heating speed.

When the thermostat is satisfied, the circuit between

terminals (4 and W) is broken, deenergizing

automatic gas valve coil (5A) and heat assist coil

(2G). After a few seconds, automatic gas valve (5A)

closes, stopping’the flow of gas to the burners. After a

longer delay, heating relay (7J) opens its contacts to

stop blower motor (3A, 3B, or 3D).

If the furnace overheats for any reason, limit control

(7H) will switch, breaking the circuit to automatic gas

valve coil (5A). After a short delay, the gas valve

closes, shutting off the flow of gas to the burners.

The furnace will continue to cycle until the fault is

corrected.

SEQUENCE OF OPERATION—COOLING

When the thermostat calls for cooling, power from

transformer (lA) energizes cooling relay coil (2C),

closing its contacts, and energizing blower motor (3A,

3B, or 3D) on its cooling speed. It continues to operate

until the thermostat is satisfied.

When the thermostat is satisfied, the circuit to ter

minal (G) is broken, deenergizing cooling relay coil

(2C) which, in turn, opens its contacts, stopping

blower motor (3A, 3B, or 3D).

—6—