Parking brake adjustment, Speed control adjustment, Making adjustments – Bolens TRANSMATIC LAWN TRACTOR 660 User Manual

Page 18

Attention! The text in this document has been recognized automatically. To view the original document, you can use the "Original mode".

Remove the hairpin ciip which secures the

disengagement rod to the stabilizer shaft assembly.

See Figure 16.

Figure 16

*

Pull the rod toward the rear of the tractor (to take up

slack), then thread the rod inward or outward

(usually only one or two turns) until the rod lines up

as precisely as possible with the hole in the

stabilizer shaft.

NOTE:

Threading

the

disengagement

rad

outward

(toward the rear of the tractor} provides for more belt

tension.

Threading

the

disengagement

rod

inward

pro vides for less beit tension.

*

Reinsert the rod and re-secure it to the stabilizer

shaft with the cotter pin removed earlier.

Check the adjustment by placing the deck engagement/

lift lever in the BLADES STOP position. The deck

should move up and forward, allowing the beit to

become loose.

*

Reassemble the shift cover panel.

*

Start the tractor’s engine and test the deck

engagemenViift lever to be certain the blades fully

disengage when in the BLADES STOP.

*

Repeat the adjustment procedure if necessary.

Parking Brake Adjustment

A

WARNING: Never attempt to adjust the

brakes while the engine is running. Always

disengage PTO, move shift lever into neutral

position, stop engine and remove key to

prevent unintended starting.

if the tractor does not come to a complete stop when

the clutch-brake pedal is completely depressed, or if

the tractor’s rear wheels can roll with the parking brake

applied, the brake is in need of adjustment. The brake

disc can be found on the right side of the transmission

in the rear of the tractor. Adjust if necessary as follows;

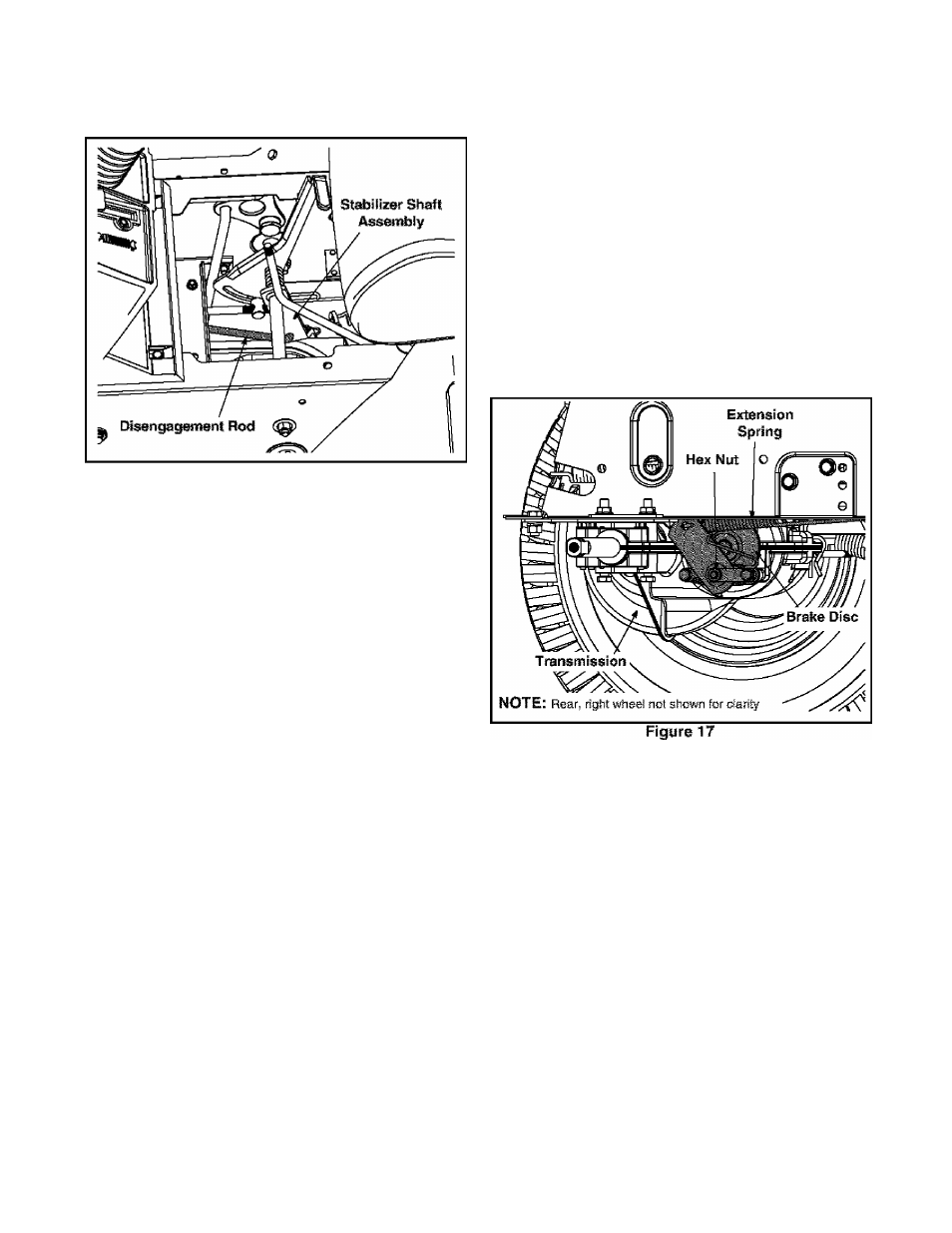

* Looking at the transmission from the right side of

the tractor, locate the extension spring and brake

disc. See Figure 17.

*

Loosen, but do NOT remove, the hex nut found on

the right side of the brake assembly. See Figure 17.

*

Using a feeler gauge, set the gap between the

brake disc and the brake puck at .011".

*

Re-tighten the hex nut loosened earlier.

Speed Control Adjustment

NOTE:

When

operating

the

unit

initiafty

or

after

replacing

the

belts,

there

wiil

be

little

difference

between the highest two speeds until after the belts

have gone through a break-in period and have seated

themselves into the pulleys.

if the full range of speeds cannot be obtained on your

unit, adjust the speed control as follows.

*

Unthread the shift knob and remove the two flange

screws which secure the shift cover panel in place.

Refer to Figure 15.

18