Step 5 — connect condensate drain line – Carrier 40QA024-060 User Manual

Page 8

8

f. Refer to the outdoor unit Installation, Start-Up and

Service Instructions for additional information.

g. Install a factory-supplied filter drier near the out-

door unit. On heat pump systems, a bi-flow filter

drier must be used.

3. Insulate and caulk wall openings to reduce air infiltra-

tion and refrigerant pipe vibrations on structure.

4. Evacuate piping, if necessary. If either refrigerant pip-

ing or the indoor coil is exposed to atmospheric condi-

tions, it must be evacuated to 1000 microns to

eliminate contamination and moisture in the system.

Step 5 — Connect Condensate Drain Line —

Observe all local sanitary codes when installing condensate

drains. Refer to Fig. 3 and 14 for drain pipe connection from

indoor unit.

1. Use hard polyvinyl chloride (PVC) pipe material with

nominal ID of

3

/

4

in. to connect at drain line. Use pipe

insulation

1

/

4

-in. thick, such as Armaflex insulation, on

exposed piping inside the conditioned space.

2. To ensure regular flow of condensate water, the drain

pipe should be pitched toward an open drain or sump

at a downward slope of at least

1

/

4

-in. per ft.

3. Attach plate with screws under piping hole.

4. Attach drain pipe with nylon wire tie passing through

hole (Fig. 15).

NOTE: Do not fasten nylon wire ties tight enough to

deform the insulation, as this affects its performance.

5. Insulate condensate drain line(s) that are located in or

above an occupied area with a condensate-proof mate-

rial such as polyurethane or neoprene.

6. Install an external trap at the end of the condensate

line.

NOTE: Should the installation require one, a conden-

sate pump may be ordered as a field-installed

accessory.

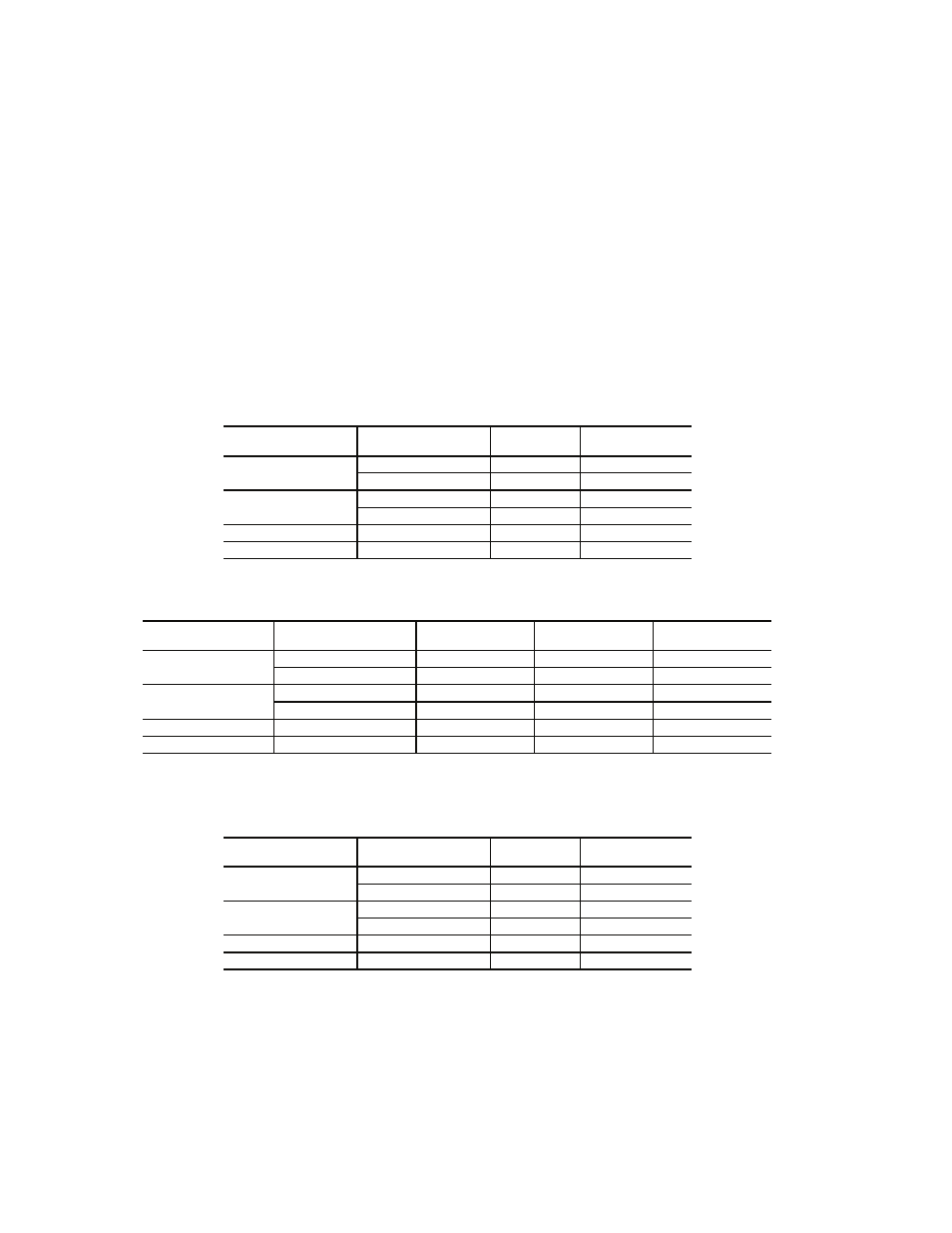

Table 4A — Piston and Charge Combinations — Cooling Only Systems

Table 4B — Piston and Charge Combinations — Heat Pump Systems

*Size 060 indoor heat pump systems use a TXV (thermostatic expansion valve), part no. EA36YD250.

Table 4C — Piston and Charge Combinations — Heat and Cool Systems

*Size 060 indoor heat pump systems use a TXV (thermostatic expansion valve), part no. EA36YD250.

COOLING

INDOOR UNIT SIZE

OUTDOOR UNIT

38HDR

PISTON

SIZE

CHARGE (lb)

024

018

57

7.0

024

57

7.75

036

030

65

10.1

036

70

8.9

048

048

80

12.2

060

060

90

12.5

HEAT PUMP

INDOOR UNIT SIZE

OUTDOOR UNIT

38QRR

PISTON SIZE

INDOOR

PISTON SIZE

OUTDOOR

CHARGE (lb)

024

018

49

40

7.5

024

55

43

7.8

036

030

65

55

12

036

70

63

13

048

048

82

73

12.2

060

060

—*

80

12.8

HEAT PUMP

INDOOR UNIT SIZE

OUTDOOR UNIT

38HDR

PISTON

SIZE

CHARGE (lb)

024

018

57

7.0

024

57

7.75

036

030

65

10.1

036

70

8.9

048

048

80

12.2

060

060

—*

12.5