Step 4 — connect refrigerant piping – Carrier 40QA024-060 User Manual

Page 7

7

TO INSTALL THERMOSTAT:

If there is at least

3

/

8

in. of space between the back of indoor

unit and wall:

1. Route thermostat wires (field-supplied) through slot in

right side or rear panel of indoor unit (Fig. 3).

2. Route wires over refrigerant and drain piping as shown

in Fig. 12.

Step 4 — Connect Refrigerant Piping —

Fan coil

units may be connected to outdoor units using field-supplied

refrigerant grade piping. Refer to Tables 3A and 3B for the cor-

rect size piping. The length of refrigerant pipe depends on the

unit placement and building structure; run pipes as directly as

possible. For piping requirements over 50 ft of total run, or

more than 25 ft of lift, consult the Residential Long Line Appli-

cation Guide.

To connect piping:

1. Install insulation. It is extremely important that all

refrigerant lines and the metering device be insulated

on heat pumps and multi-splits. On cooling only units,

the liquid line may be left uninsulated. Use any accept-

able heat resistant closed-cell foam insulation (mini-

mum

3

/

8

-in. wall thickness). When insulating piping,

cap ends and slide insulation over the piping. Insula-

tion can also be cut and placed over piping.

2. Run liquid and gas refrigerant piping.

a. Run pipes as directly as possible, and avoid any

unnecessary turns and bends.

b. Suspend refrigerant pipes so that the insulation is

not damaged and vibrations are not transmitted to

the structure.

c. Leave slack in the refrigerant pipe between the

structure and the unit to absorb vibrations.

d. A piston is shipped in the factory-installed meter-

ing device body (Fig. 13) with the indoor unit. Use

Tables 4A-4C to verify that you have the required

piston size for the system being installed.

e. For special applications such as long lines or raised

elevations, consult the Residential Long Line

Application Guide for specific system require-

ments. The arrow on the metering device body

must face away from the indoor coil.

IMPORTANT: Do not route wires under the piping, or

wires could impede air filter removal.

DO NOT BURY MORE THAN 36 IN. OF REFRIGER-

ANT PIPE IN THE GROUND. If any section of pipe is

buried, there must be a 6-in. vertical rise to the valve con-

nections on the outdoor unit. If more than the recommended

length is buried, refrigerant may migrate to the cooler, bur-

ied section during extended periods of unit shutdown, caus-

ing refrigerant slugging and possible compressor damage at

start-up.

IMPORTANT: The metering device is factory-

installed and only needs to be replaced for long line

applications or if the system combination requires it.

See Tables 4A-4C. See Fig. 13.

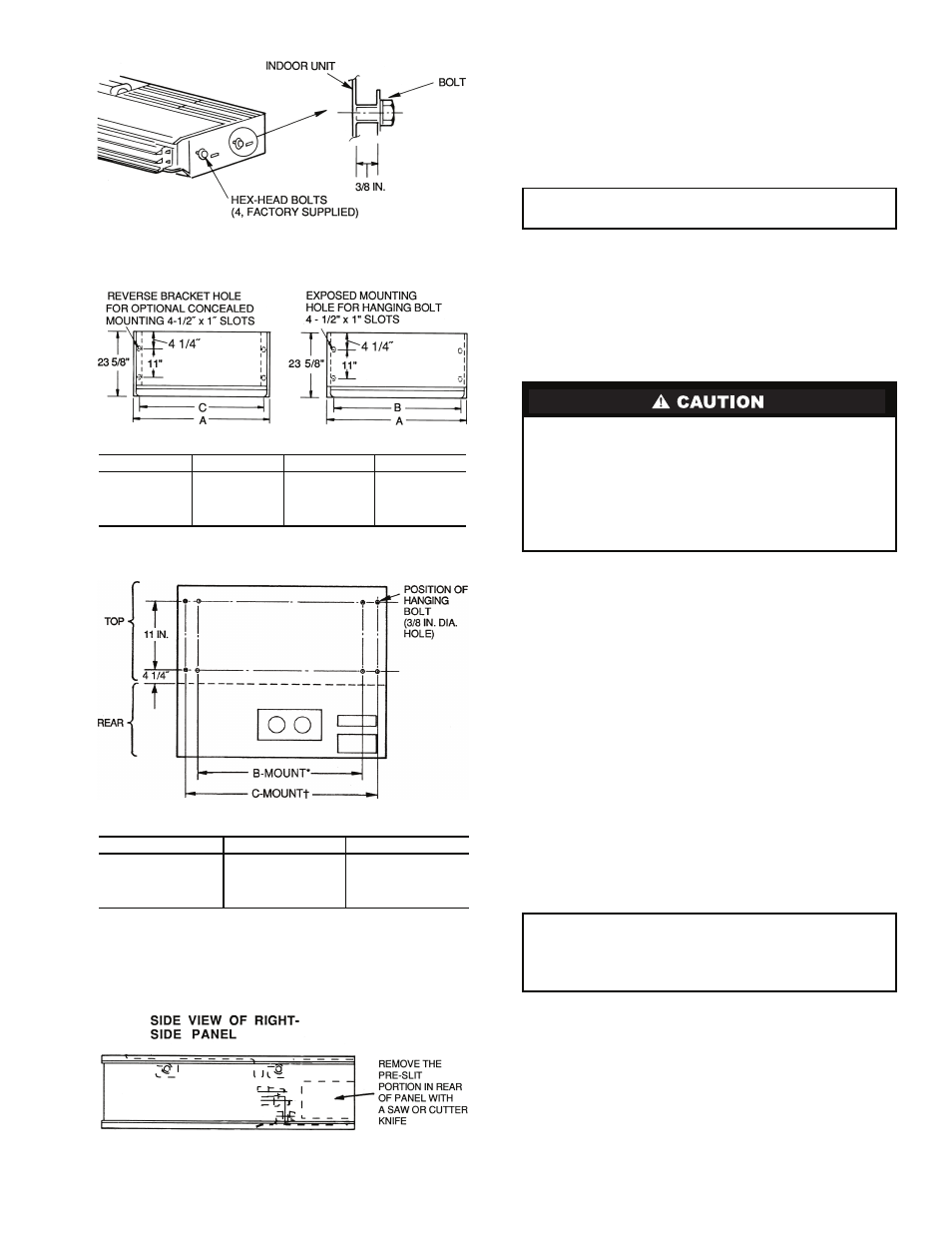

Fig. 6 — Installing Hex-Head Mounting Bolts

in Fan Coil Unit

DIMENSIONS (in.)

Fig. 7 — Fan Coil Unit Hanging Dimensions

UNIT SIZE

A

B

C

024

50

15

/

16

46

49

5

/

8

036

58

13

/

16

53

7

/

8

57

1

/

2

048

71

9

/

16

66

5

/

8

70

1

/

4

060

92

87

90

5

/

8

DIMENSIONS (in.)

*Exposed mounting holes.

†Reverse bracket holes (concealed mounting).

Fig. 8 — Mounting Included with

Fan Coil Unit

UNIT SIZE

B

C

024

46

49

5

/

8

036

53

7

/

8

57

1

/

2

048

66

5

/

8

70

1

/

4

060

87

90

5

/

8

Fig. 9 — Removing Rear Knockout in Side Panel

if Right-Side Piping Connection is Used