Carburetor adjustment, D. carburetor adjustment -19, Maintenance and repair instructions – Ryobi 310BVr User Manual

Page 18

Attention! The text in this document has been recognized automatically. To view the original document, you can use the "Original mode".

MAINTENANCE AND REPAIR INSTRUCTIONS

8. Place heat shield/muffler on a flat, stable surface with

the heat shield facing down. Reinstall the spark

arrestor by pressing it into the recessed hole in the

muffler. Make sure it fits tightly against the muffler

and is not raised up, bent, or wrinkled once in place.

9. Pick up the unit. If necessary, align muffler bolt holes

with the bolt holes in heat shieid. Insert muffler

mounting boits into holes of heat shield and through

the muffler.

10. Place heat shield/muffler on a flat, stable surface with

the heat shield facing down. Place exhaust gasket

over bolts sticking through the muffier and on top of

the spark arrestor (Fig. 33).

11. Hold heat shield/muffler with finger over the exhaust

gasket to keep it in place. Turn over and align boits

with boit holes in the engine. Push bolts into the

engine hoies and reiease gasket once bolts are

started. Do not tighten bolts completely.

12. Reinstall four (4) screws to attach top heat shield to

bottom heat shield.

13. Tighten muffler mounting bolts.

14. Reassemble the housing unit. Reaiign the two

housing units and screw holes. Make sure all wires

and other parts are completeiy within the housing

units and are not crimped, pinched, or sticking out.

Reinstall the 10 screws.

CARBURETOR ADJUSTMENT

NOTE: Careless adjustments can seriously damage

your unit. An authorized service dealer should

make carburetor adjustments.

Check Fuel Mixture

Old and/or improperly mixed fuel is usually the reason

for the unit not running properly. Drain and refill the tank

with fresh, properly mixed fuei prior to making any

adjustments. Refer to Oil and Fuel Information, Pg. 12.

Clean Air Filter

The condition of the air filter is important to the

operation of the unit. A dirty air filter will restrict air flow

and change the air/fuel mixture. This is often mistaken

for an out of adjustment carburetor. Check the condition

of the air filter before adjusting the idle speed adjuster.

Refer to Air Fiiter Maintenance Pg. 15.

Adjusting the Carburetor

If after checking the fuel mixture and cieaning the air

fiiter the engine stiii will not idle, adjust the idle speed as

follows.

1. Make the initial settings with the engine stopped.

These initial settings should allow you to start and

warm up the unit before making the final adjustments.

A

WARNING:

This unit wiii need to be running

during idle speed adjustment. Wear

protective clothing and observe all safety

instructions to prevent serious personal injury.

Do not set unit on any surface except a clean,

hard area while starting or performing any

adjustments. Debris such as gravel, sand,

dust, grass, etc. could be picked up by the air

intake and thrown out by the discharge

opening, damaging unit, property, or causing

serious injury to bystanders or operator.

initial Idle Speed Setting

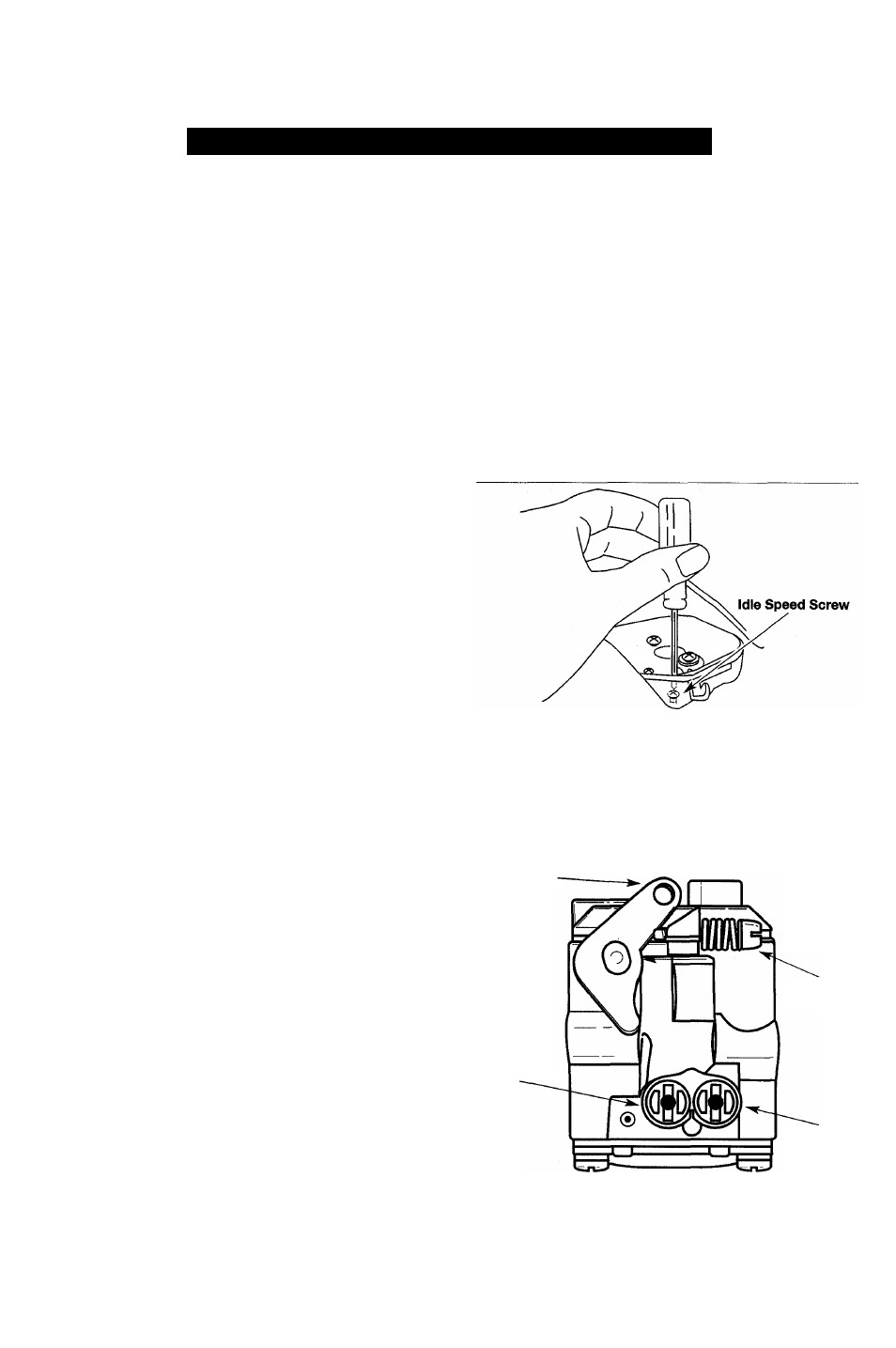

2. Remove the air filter cover and insert a screwdriver

through the opening in the air filter base (Fig. 35).

-------------------------------------------- Fig. 35-------------------------------------------

3. Back the idle speed screw (Fig. 36) out

(counterclockwise) until it does not contact the

carburetor throttle lever. Then turn the screw in

(clockwise) until it just begins to move the throttle

lever; then continue turning for 2 more full turns.

Throttle

Lever

Idle Speed

Screw

Idle Speed

Mixture

Needle

High Speed

Mixture

Needle

Fig. 36

18