G.trouble shooting chairr, G. trouble shooting chart – Poulan 2100 User Manual

Page 21

Attention! The text in this document has been recognized automatically. To view the original document, you can use the "Original mode".

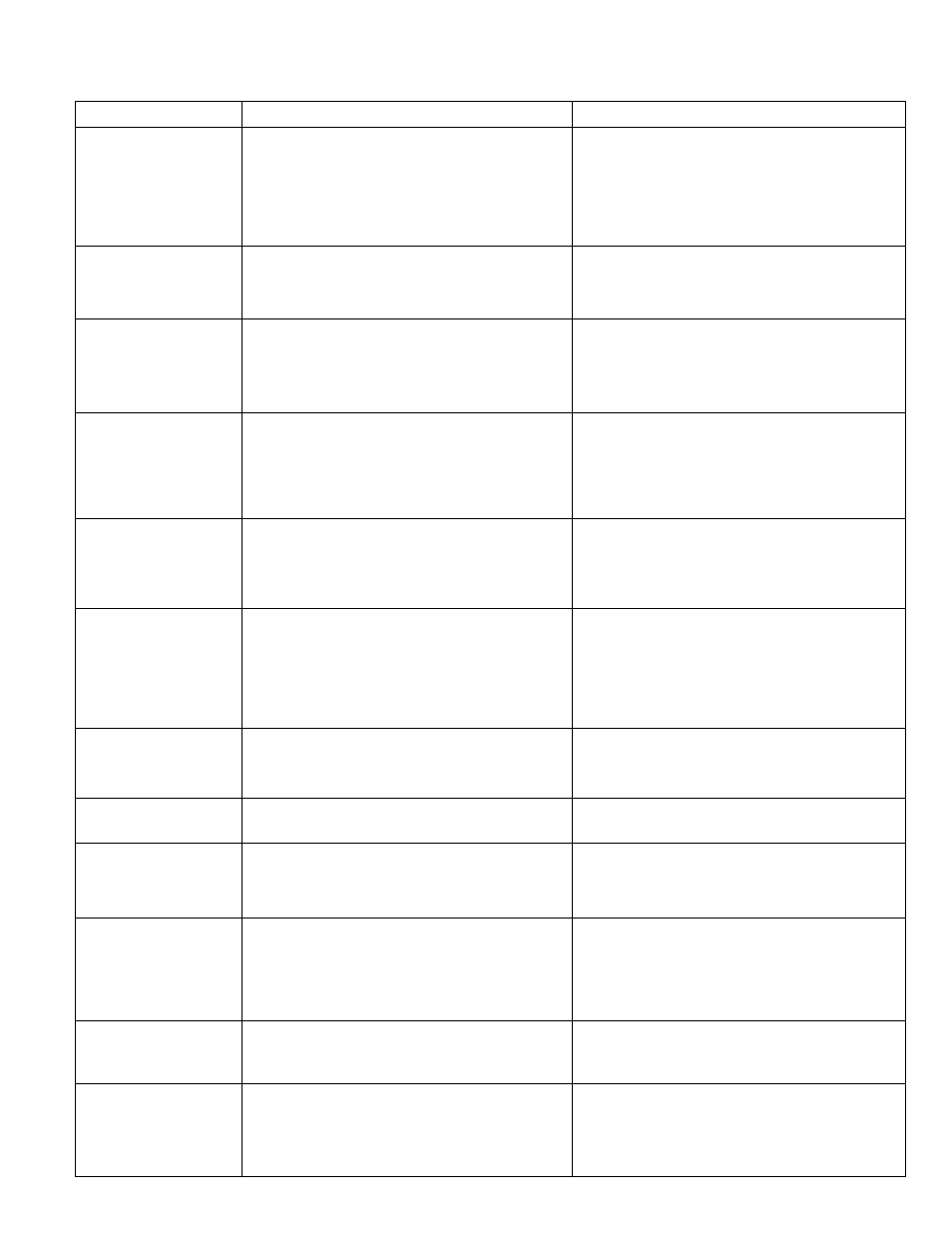

G.TROUBLE SHOOTING CHAirr

SYMPTOM

CAUSE

REMEDY

Engine will not

start or will run

only for a few

seconds after

starting.

1. Fuel empty.

2. Enjipno nooded.

3. Spark plug not firing.

4. Fuel not reaching carburetor.

i>, (carburetor requires adjustment.

6. Ignition Switch Off.

7. None of the above.

1. Fill tank with correct fuel mixture

2. See ‘'Starting Instructions.”

3. Install new^ug/check ignition system.

4. Clean fuel inter; inspect fuel line.

5. See “Carburetor Adjustments.”

6. Move switch to the ^START” position,

7. Contact your Service Dealer.

Engine will not

stop running.

1. The switch wire is not connected.

2. Not the above.

1, Move choke lever to full choke until en-

Me to stops running; then, remove fan

housing and connect the switch wire.

2, Contact your Authorized Service Dealer.

En^e will not

idle properly.

1. Idle speed set too fast or too slow.

2. Low speed mixture requires adjustment.

3. Cranl^hafl seals worn.

4. Compression low.

5. None of the above.

1. See “Carburetor Adjustments,”

2. See “Carburetor Adjustments,”

3. Contact your Authorized Service Dealer,

4. Contact your Authorized Service Dealer.

5- Contact your Authorized Service Dealer

Engine will not

accelerate,lacks

power, or dies

under a load.

1. Air filter dirty.

2. ^ark plug fouled.

3. Cfarburetor requires adjustment.

4. Exhaust ports or mufiler outlets plugged,

5. Compression low.

6. None of the above.

1. Clean or replace air filter,

2. Clean or replace spark plug and re-gap.

3. See “Carburetor Adjustments.”

4. Contact your Authorized Service Dealer.

5. Contact your Authorized Service Dealer.

6- Contact your Authorized Service Dealer.

Engine

smokes

excessively.

1. Air filter dirty.

2. Fuel mixture incorrect.

3. High speed mixture requires adjustment.

4. Choke partially on.

5. Crankcase leak.

1. Clean or replace air filter.

2. Refuel with correct fuel mixture,

3. See “Carburetor Adjustments.”

4. Push Choke knob in,

5. Contact your Authorized Service Dealer.

Engine runs hot.

1. Fuel mixture incorrect,

2. High speed mixture set too low (Lean).

3. Spark plug incorrect.

4. Exhaust ports or mufiler outlets plugged.

6. Carbon build-up on muffler outlet screen.

6. Fan housing/CThnder fins dirty.

7, None of the above.

1. See “Fueling Your Unit.”

2. See “Carburetor Adjustments.”

3. Replace with correct plug.

4. Contact your Authorized Service Dealer.

5. Clean spark arrestor screen.

6. Clean

7. Contact your Authorized Service Dealer,

Oil inadequate for

bar and chain

lubrication.

1. Oil tank empty

2. Improperly adjusted oiler (if so equipped).

3. Oil pump or oil filter clog^d.

4. Guide oil hole blocked-

1. Fill oil tank.

2. Adjust Oder.

3. Contact your Authorized Service Dealer,

4. Remove bar and clean.

Chain moves at

Idle Speed.

1. Idle speed requires adjustment.

2. Gluten requires repair.

1. See “Carburetor Adjustments,”

2, Contact your Authorized Service Dealer.

Chain does not move

when engine is

accelerated.

1. Chain tension too tight.

2. Carburetor requires a

4. Clutch slipping.

1. See “Chain Tension,”

2. See “Carburetor Adjustments.”

3. Repair or replace.

4. Contact your Authorized Service Dealer.

Chain datters

or cuts roughly.

1. Chain tension incorrect.

2. Cutters damaged.

3. Chain worn.

4. Cutters duH, improperly sharpened, or

depth gauges too high.

5. Sprocket worn.

1. See “Chain Tension.”

2. Contact your Authorized Service Dealer,

3. Resharpen or replace chain.

4. See the chain sharpening instructions.

5. Contact your Authorized Service Dealer.

Chain stops wdtbin

the cut.

1. Chain cutter tops not filed flat.

2. Guide bar burred or bent; rails uneven.

3. Clutch slipping.

1. See the chain sharpening instructions.

2. Repair or replace guide bar.

3. Contact your Authorized Service Dealer.

Chain cuts at an

angle.

1, Cutters damaged on one side.

2. Chain dull on one side.

8. Guide bar bent or worn.

1. Resharpen until all cutters have equal

angles and lengths.

2. Resharpen until all cutters have equal

angles and lengths.

3. Replace guide bar.

-

21

-