A. guide bar and chain, A guide bar and chain, General maintenance – Poulan 2100 User Manual

Page 16

Attention! The text in this document has been recognized automatically. To view the original document, you can use the "Original mode".

GENERAL MAINTENANCE

A good maintenance program of regular inspection

and care wiU increase the service life and help to main

tain the safety and performance of your saw

• Check saw for loose bolts, screws, nuts, and

fittings regularly Loose fastened can cause an

unsafe condition as well as damage to your saw

• Make all adjustments or repairs (except car

buretor adjustments) with:

— spark plug wire disconnected.

— engine cool as opposed to a saw that has just

been run.

A

WARNING

Have all chain saw service performed by a quali-

Red service dealer other than the items listed in

the maintenan<^ section of this manuaL

A. GUIDE BAR AND CHAIN

Increase the service life of your Guide Bar and

Chain Ъу:

~ Usiagthe sawproperly and as recommended in this

mani^.

— Maintaining correct chain tension, page 8,

— Proper lubrication, page 10.

— Regular maintenance as described in this section.

1. CHAIN MAINTENANCE

• Sharpen the chain when:

— wood chips are small and powdery.

Wood chips made by the saw chain should be

about the size of the teeth of the chain.

— saw has to be forced through the cut.

— saw cuts to one side.

I CAUTION: ! Always wear gloves when handling the

chain. The chain can be sharp enough to cut you

even though it is too dull to cut wood.

a. SHARPENING INSTRUCTIONS

Items required:

Gloves

Flat File

5/32” Diameter File

Depth Gauge

6” Fde Holder

1.

) Stop the engine and disconnect the

spark plug.

2.

) Adjust the chain for proper tension. Page 8.

3.

) Work at the midpoint of the bar, moving the

chain forward by band as each cutter is filed.

4.

) Sharpen Cutters.

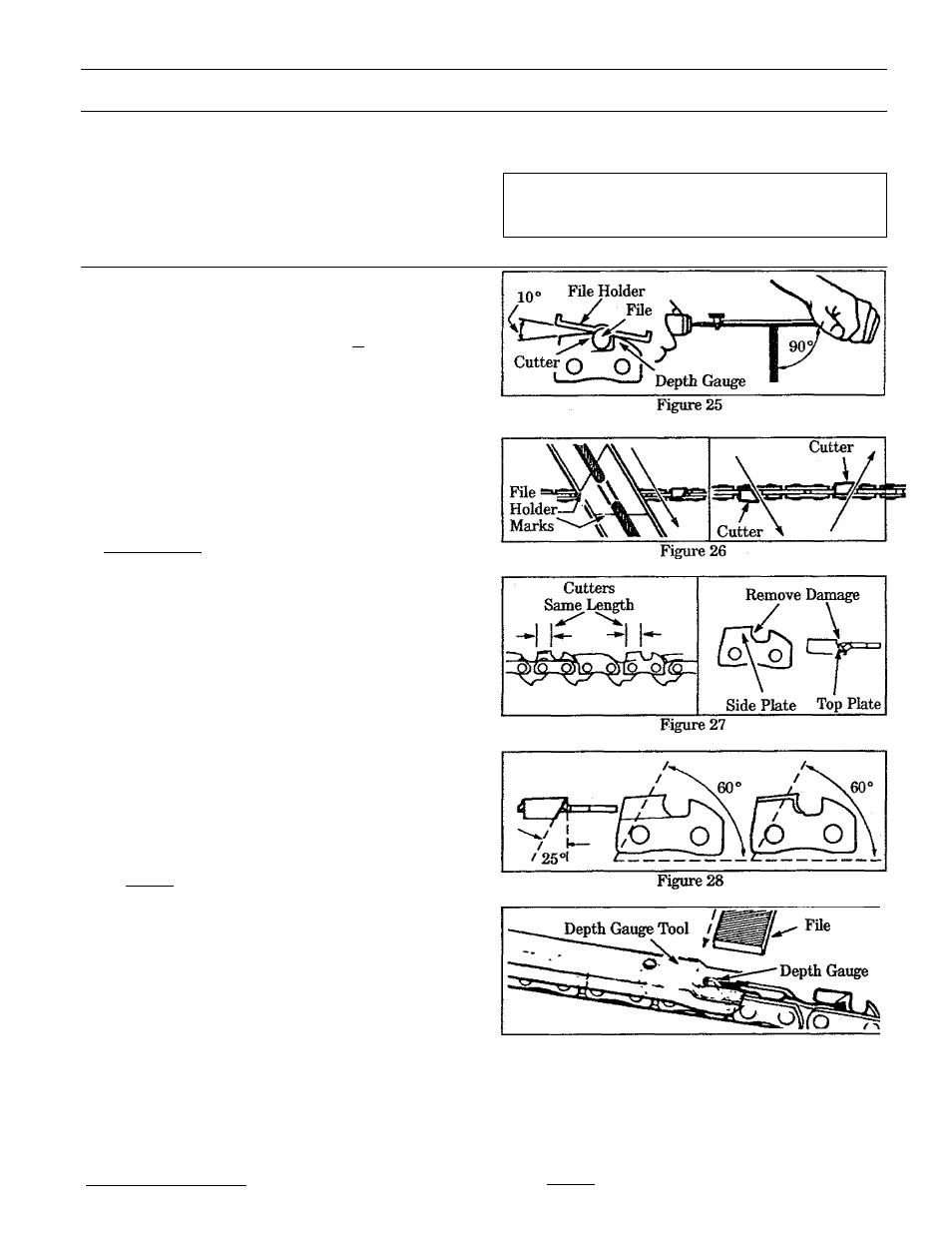

a. ) Position the file holder level at a 10®

angle on the top plate of the cutter and

depth

Figure 25 .

b. ) Ahgn the 25° file holder marks with the

bar and parallel to the center of the chain.

Figures 26 & 28 .

NOTE: If your file holder has a 30° mark, disre

gard this mark and file at a 25° angle.

c. ) File from inside toward outside of cutter,

straight across on forward stroke in one

direction only. Use 2 or 3 strokes per cut

ting edge. Figure 27.

d.

) Keep all cutters the same length. Fig

ure 27.

e. ) File enough to remove any damage to the

cutting edges (side plate and top plate) of

the cutter. Figure 27 ,

£) File chain to meet specifications shown in

Figure 28,

A

WARNING

”

Maintain the proper hook angle according to the

manufacturers speciRcation for the chain you

are using. Too much hook an^e will increase the

chance of kickback which can result in serious

ццшу. Figures 28 & 30 .__________________________

Figure 29

5.) Correct Depth Gauges

a.) Place depth gauge tool over each cutter

depth gauge. Figure 29 .

h.) Fife depth gauge with a flat file until it is

A

gauge with a flat file. Figures 29 & 30.

NOTE: The veiy top of the depth gai^ should be

flat with the front half rounded off with a flat file.

-

16

-