B. spark arrestor, B. spaik arrestor – Poulan 2100 User Manual

Page 17

Attention! The text in this document has been recognized automatically. To view the original document, you can use the "Original mode".

í

A WARNING

TheDe;

et* dept^

will increase tlie chance of hickback which can

result in serious iidnry*

h. CHAIN REPLACEMENT

1,

) Use only the Low-Kickback replace

ment chain specified for your saw in

the “Specifications” section.

2, ) Replace the chain when cutters or

links break.

3.

) See a qualified service dealer to re

place or sharpen your chain.

4.

) iUways have a worn sprocket replaced

by a qualified service dealer when in

stalling a new chain to avoid excessive

wear to the chain.

2. GUIDE BAR MAINTENANCE

•

Conditions which can require guide bar

maintenance:

— saw cuts to one side.

— saw has to be forced through a cut.

— inadequate supply of oil to bar and

chain.

•

Checkthe condition of the guide bar each

time the chain is shar^ned. A worn guide

bar will damage the chain and make cutting

more difficult.

• Replace the guide bar when:

— the inside groove of guide bar rails is worn,

— the guide bar is bent or cracked. See Fig

ure 32,

• Use only the replacement Reduced-Kick

back Guide Bar specified for your saw in

the “Specification** section.

a. Remove the guide bar to service.

b. Clean the oil holes at least once after every

five hours of operation.

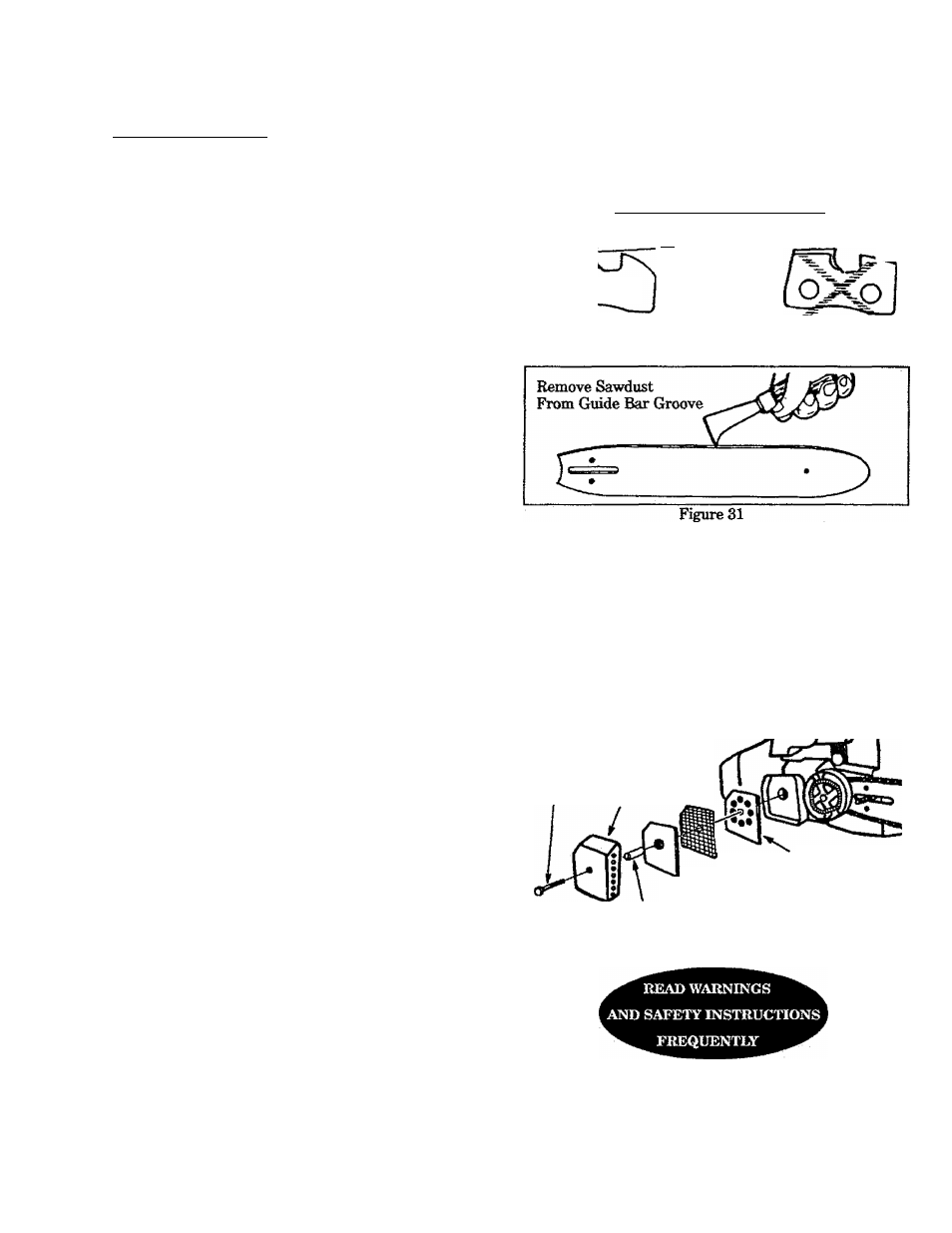

c. Remove sawdust from the pfuide bar groove

periodicallywithaputtyknifeorawire.

Fig

ure 31.

d. Remove burrs by filing the side edges of the

guide bar grooves square with a flat file. Fig-

ure32.

e. Restore square ed^s to an uneven rail top be

filing with a flat file. Figure 32 .__________

Hook^ngie

.025*

^ \

Too Much

Squared

Hook Ande^'"^ Off Comer

o o

Bounded

Comer

Right Way

Wrong Way

Figure 30

Correct

Guide Bar

Groove

Worn Grooves

File Edges

Square

Figure 32

B. SPARK ARRESTOR

•

Carbon deposits build up on the spark arres

tor as the sawis used and must be removed to avoid

creating a fire hazard or causing engine damage.

• Replace the spark arrestor if breaks occur.

• Keep the spark arrestor clean at all. times.

Clean:

—as required.

—at least once for each 25-30

hours of operation.

Items required: wire brush, 3/8” wrench

1. Disconnect the spark plug wire.

2. Remove the muffler cover screw. Remove the

muffler cover. Figure 33 .

3. Remove the spark arrestor screen. Figure 33 .

4. Clean the screen with a wire brush or replace if

breaks are found.

5. Reassemble parts.

Muffler

Cover

Muffler

Screw Coyer

N

Spacer Baffle Plate

Baffle Plate

Spark Arrestor Screen

Figure 33

-

17

-