To transport log splitter, Maintenance, Reservoir fluid – MTD 242-610-000 User Manual

Page 8: Strainer tube assembly, Beam and splitting wedge, Hose clamps, Engine

Attention! The text in this document has been recognized automatically. To view the original document, you can use the "Original mode".

FIGURE 10.

A

WARNING: If the fluid becomes exces

sively hot at any time during operation,

stop the unit and aiiow the fiuid 1o cooi

down. Maximum performance wili not be

obtained from your log splitter if th e fiuid

is too hot. Use extreme caution as con

tacting hot fiuid could result in serious

personai injury.

TO TRANSPORT LOG SPLITTER

Attach the hitch to a towing vehicle, making certain to

latch securely. Attach the safety chains to the towing

vehicle.

MAINTENANCE

A

WARNING: Always stop the engine and

disconnect the spark plug wire before

performing any maintenance or idjust-

ments.

RESERVOIR FLUID

Check the hydraulic fluid level in the log splitter reser

voir tank before each use. Refer to “Before Starting”

under Operation Section.

Change the hydraulic fluid in the reservoir evsry 100

hours of operation. Remove the six hex bolts, lock

washers and hex nuts which hold the end plat 3 to the

beam. See figure 11. Remove the plate, and drain the

fluid into a suitable container. Refill using only Dexron

II automatic transmission fluid, as instructed in the

“Initial Preparation” section of this manual, 3age 6.

Also, make certain to clean the strainer tube assembly.

NOTE: Drain the fluid and flush the reservoir tank and

hoses with kerosene whenever any repair work is per

formed on the tank, hydraulic pump or valve.

Contaminants in the fluid will damage the hydraulic

components. (Should be performed by an authorized

service dealer.)

A

WARNING: Use extreme caution when

working with kerosene, as it is an

extremeiy fiammable fluid.

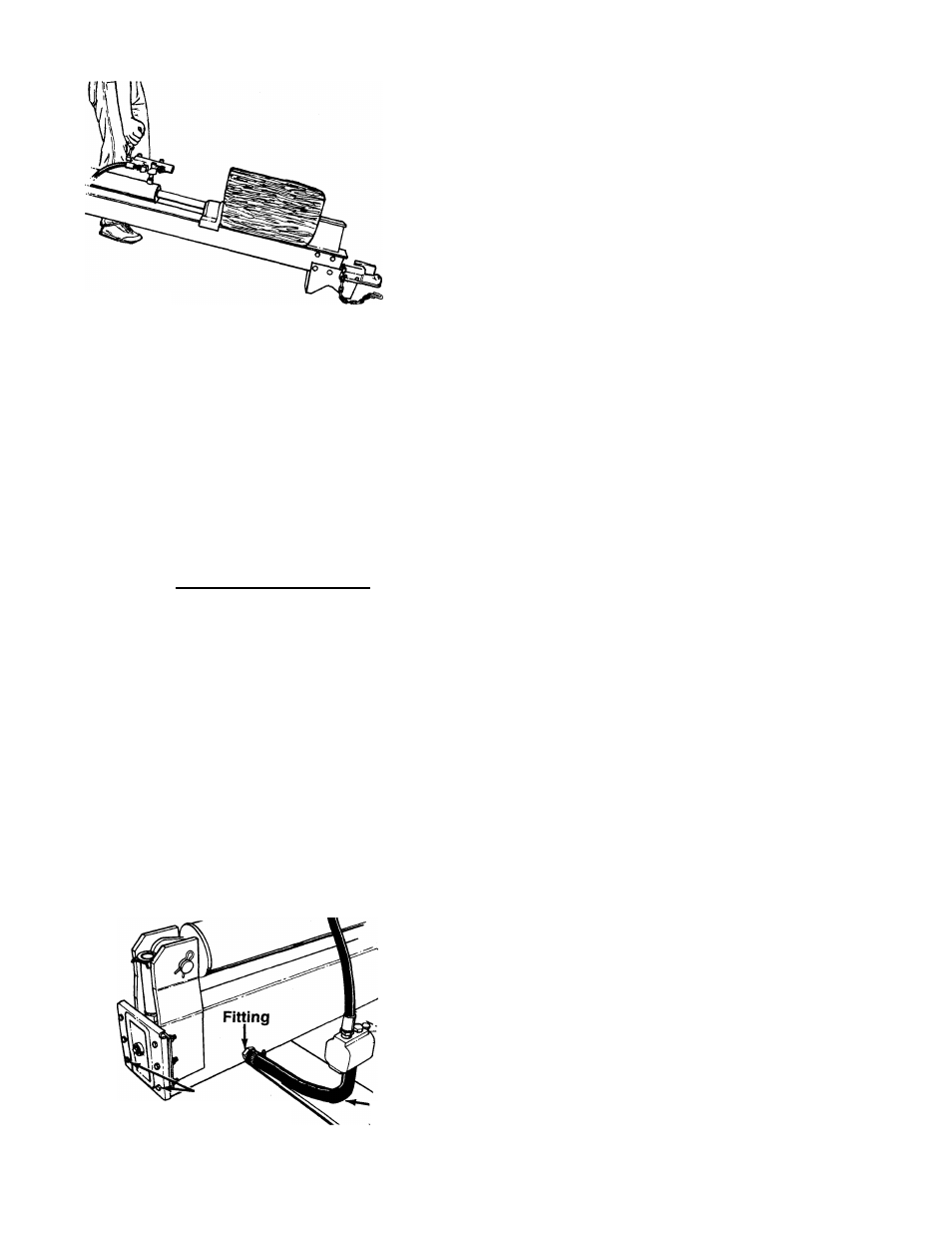

FIGURE 11.

'Hex Bolts

Lock Washers

Hex Nuts

Suet on

Hosie

STRAINER TUBE ASSEMBLY

1. Loosen the hose clamp on the suction hose at

the beam. See figure 11. Disconnect the hose

from the beam.

2. Using an adjustable wrench, remove the fitting

from the beam.

3. Reach inside the end of the beam (end plate was

already removed), and pull out the strainer tube

assembly. See reference number 43 on page 10.

4. Clean the strainer tube assembly with kerosene.

Reassemble in reverse order.

5. Reassemble the end plate. Refill reservoir tank

with Dexron II automatic transmission fluid as

instructed under “Initial Preparation” in Operation

Section.

BEAM AND SPLITTING WEDGE

Lubricate the beam where it contacts the ram with

grease before each use to obtain years of service.

HOSE CLAMPS

Check the hose clamps on the suction hose (attached

to bottom of the pump) for proper tightness before

each use. Check the hose clamps on the return hose

(between beam and cylinder) at least once a season.

ENGINE

Refer to the separate engine manual for all engine

maintenance instructions.

Maintain engine oil as instructed in the separate

engine manual packed with your unit. Read and follow

instructions carefully.

Service air cleaner every 25 hours under normal con

ditions. Clean every few hours under extremely dusty

conditions. Poor engine performance and flooding

usually indicates that the air cleaner should be ser

viced. To service the air cleaner refer to the separate

engine manual packed with your unit.

The spark plug should be cleaned and the gap reset

once a season. Spark plug replacement is recom

mended at the start of each season; check engine

manual for correct plug type and gap specification.

Clean the engine regularly with a cloth or brush. Keep

the cooling system (blower housing area) clean to

permit proper air circulation which is essential to

engine performance and life. Be certain to remove all

dirt and combustible debris from muffler area.