Engine air filter, Carburetor adjustment, Cooling system – Troy-Bilt 12001 User Manual

Page 17: Spark plug

Attention! The text in this document has been recognized automatically. To view the original document, you can use the "Original mode".

5. Place the nozzle of a grease gun onto the rim

of the fill hole. Push the nozzle of the grease

gun against the opening to seal the nozzle of the

gun against the rim of the fill hole.

6. Apply grease into the transmission until

grease begins to come from the air vent hole.

7. Reinstall the fill hole plug and the air vent

screw. Tighten them securely.

8. Reinstall the right-side tines. See “Tine

Removal and Installation,” this Section, for rein

stallation instructions. Before reinstalling the

tines, use a fine sandpaper to clean any rust off

the tine shaft. Then coat the tine shaft with a

few drops of oil or anti-seize compound to make

future tine removal easier.

ENGINE

AIR

FILTER

After using your Tiller for 25 operating hours or

after a 3-month period (more frequently in dirty

or dusty areas), the engine air cleaner filter will

need to be cleaned and re-oiled.

Use the following instructions:

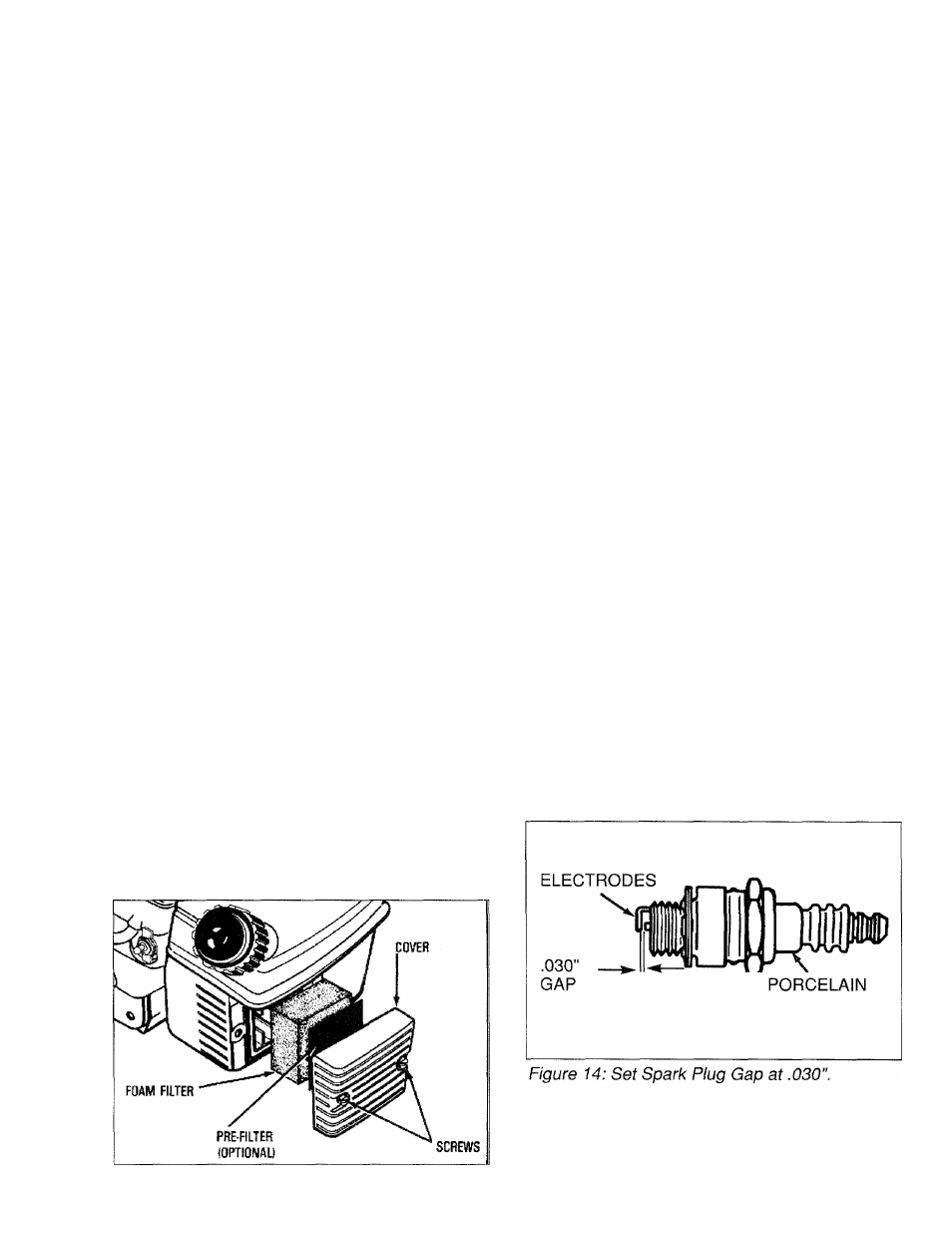

1. Remove the air cleaner outer cover by taking

out the two cover screws shown in Figure 13.

Put the cover aside. Remove the optional pre-fil

ter (if so equipped) and the thicker foam filter.

Clean the body of the air filter housing and the

cover with a clean rag.

2.

Inspect the pre-filter (if so equipped) and thick

foam filter for dirt. If dirty, continue with step 3.

3. Wash the thick foam element in a detergent

and water solution. Squeeze to remove dirt— do

not twist it.

4. Rinse the foam filter in clean water thoroughly.

5. Wrap in a cloth and squeeze until dry.

6. Saturate the foam filter with clean engine oil

and squeeze out any excess oil.

7

.

If you have the optional pre-filter, it should be

washed in a water and detergent solution, rinsed

thoroughly in clean water, and air dried.

8

. Reassemble all components carefully.

CARBURETOR ADJUSTMENT

Your Tiller is designed to run at full speed

when you are tilling or cultivating with it. When

you release the throttle lever, the engine should

return to its idle speed.

NOTE

The tines may slowly rotate when you have them

out of the soil and the engine is idling.

The tines should stop rotating (when engine is

idling) when you lower the tines into soft soil.

If the tines continue to rotate (when engine is

idling) in soft soil, the idle speed may be set too

high or the centrifugal clutch may be malfunc

tioning.

If you think your carburetor or the engine

speed require adjustment, see your nearest

Authorized Tecumseh Service Outlet.

Never tamper with the engine governor which

is factory-set for the proper engine speed.

Overspeeding the engine above the factory

high-speed setting can be dangerous.

COOLING SYSTEM

Important

— Frequently remove grass clip

pings, dirt and debris from the engine cooling

fins, around the air intake screen and levers and

linkage. This will help to ensure adequate cool

ing and correct engine speed.

SPARK PLUG

Check the spark plug once yearly or every 100

operating hours. Clean around the spark plug,

then remove it for inspection. Replace the plug if

the electrodes (see Figure 14) are pitted or

burned, or the porcelain is cracked.

Check the electrode gap with a wire feeler

gauge and adjust the gap to .030" if necessary.

Figure 13: The Engine Air Fiiter Assembiy.

17