Engine lubrication, Transmission lubrication, Maintenance – Troy-Bilt 12001 User Manual

Page 16

Attention! The text in this document has been recognized automatically. To view the original document, you can use the "Original mode".

Remounting the tine gangs takes just a couple

of minutes and you’ll need a pliers at most. The

Figures to the right show the conventional tine

configuration where there is a narrow gap be

tween the center (inner) tines, and the special

stony soil tine pattern where the inner tine gangs

have been swapped in position. The stony pat

terns creates a much wider gap between the

inner tine gangs— rocks are much less likely to

become lodged between them and the tine hood.

Important— Remember that when you re

mount the tines on the tine shaft, they must be

turned in the direction that allows the curved por

tions of the blades to enter the soil first! Don’t

turn the tines so they face backwards or tilling

will be very difficult.

Figure 11D: Normal tine gang pattern.

Figure 11E: Tine gang pattern for very stony soii.

Section 4:

Maintenance

ENGINE LUBRICATION

The engine on your Tiller is a two-cycle (“two-

stroke”) engine. Engine lubrication is provided

by mixing the proper type and amount of two-

cycle oil with the gasoline. Refer to “The

Gasoline/Two-Cycle Engine Oil Mixture” for cor

rect proportions and mixing instructions.

Attempting to run the engine on just gasoline

alone (without the correct amount and type of

two-cycle oil mixed with it) will cause the engine

to overheat and seize up from lack of lubrication.

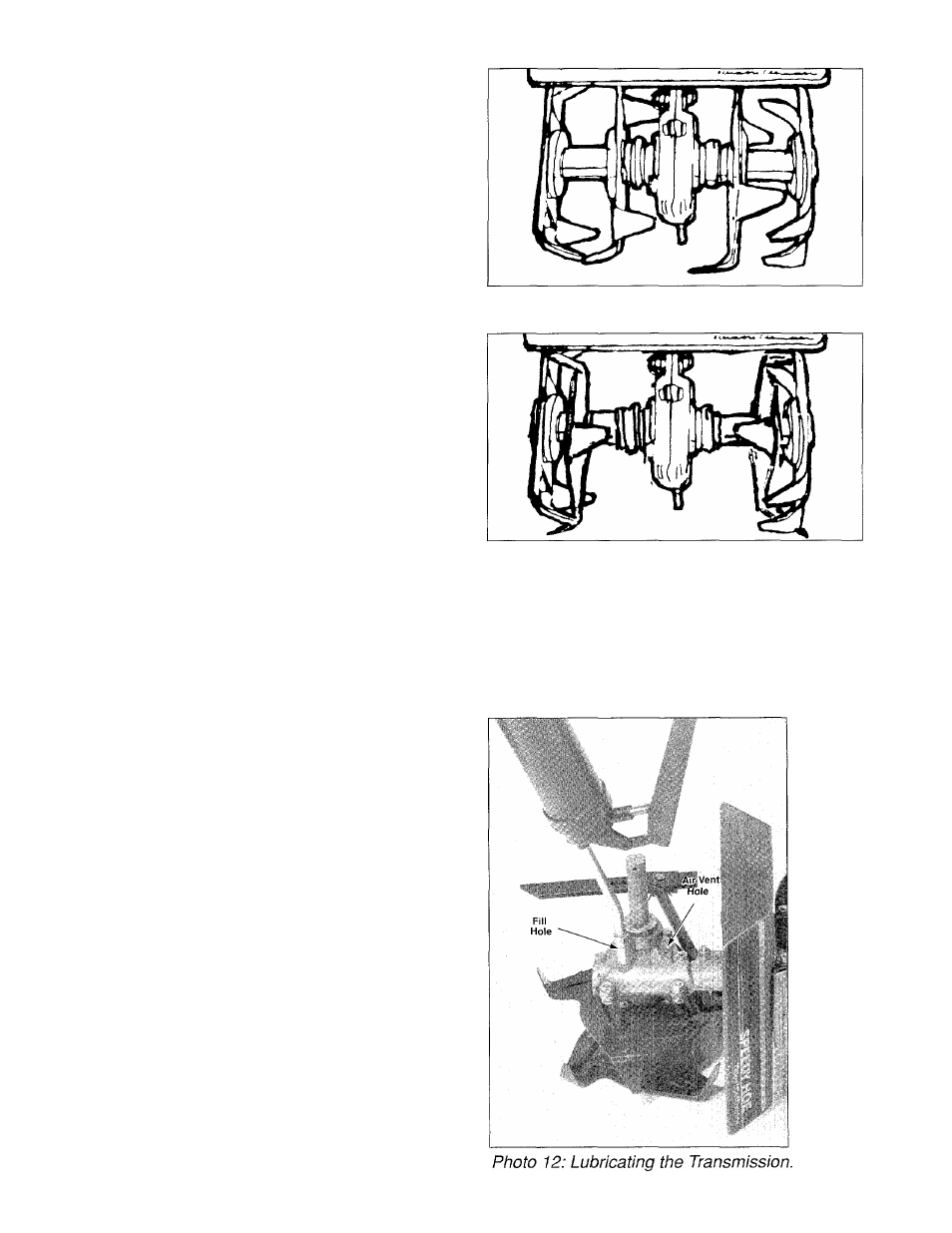

TRANSMISSION LUBRICATION

After the initial five hours of operation, and

every twenty-five operating hours afterward, the

transmission should be lubricated with grease.

Replacement grease should be a high quality,

automotive petroleum-base grease usually avail

able at most hardware or auto parts stores.

To lubricate the transmission:

1. Lay the machine on the left side so that the

tine shaft is vertical.

2. Remove both right-side tines. See “Tine

Removal and Installation,” this Section, for in

structions.

3. Clean any dirt or debris away from the trans

mission so that none will enter the housing.

16

4. Use a 3/16” alien wrench to remove the air

vent screw and the fill plug from the right side of

the transmission housing. See Photo 12.