Note, Throttle control adjustment, Lubrication – MTD 94-2105-B User Manual

Page 14: Warning, Maintenance, Trouble shooting, Engine, Cleaning the tine area, Transmission, Lubrication maintenance

Attention! The text in this document has been recognized automatically. To view the original document, you can use the "Original mode".

Minor carburetor adjustment may be required to

compensate for differences in fuel, temperature,

altitude or load. If adjustments are needed, refer to

the engine section of this manual.

NOTE

A dirty air cleaner will cause engine to

run rough. Be certain air cleaner is

clean and attached to the carburetor

before adjusting carburetor. Do not make

unnecessary

adjustments.

Factory

settings are satisfactory for most appli

cations and conditions.

THROTTLE CONTROL ADJUSTMENT

To obtain satisfactory engine performance, the engine

throttle control must be adjusted properly. If it is

necessary to check the engine control adjustments,

proceed as follows.

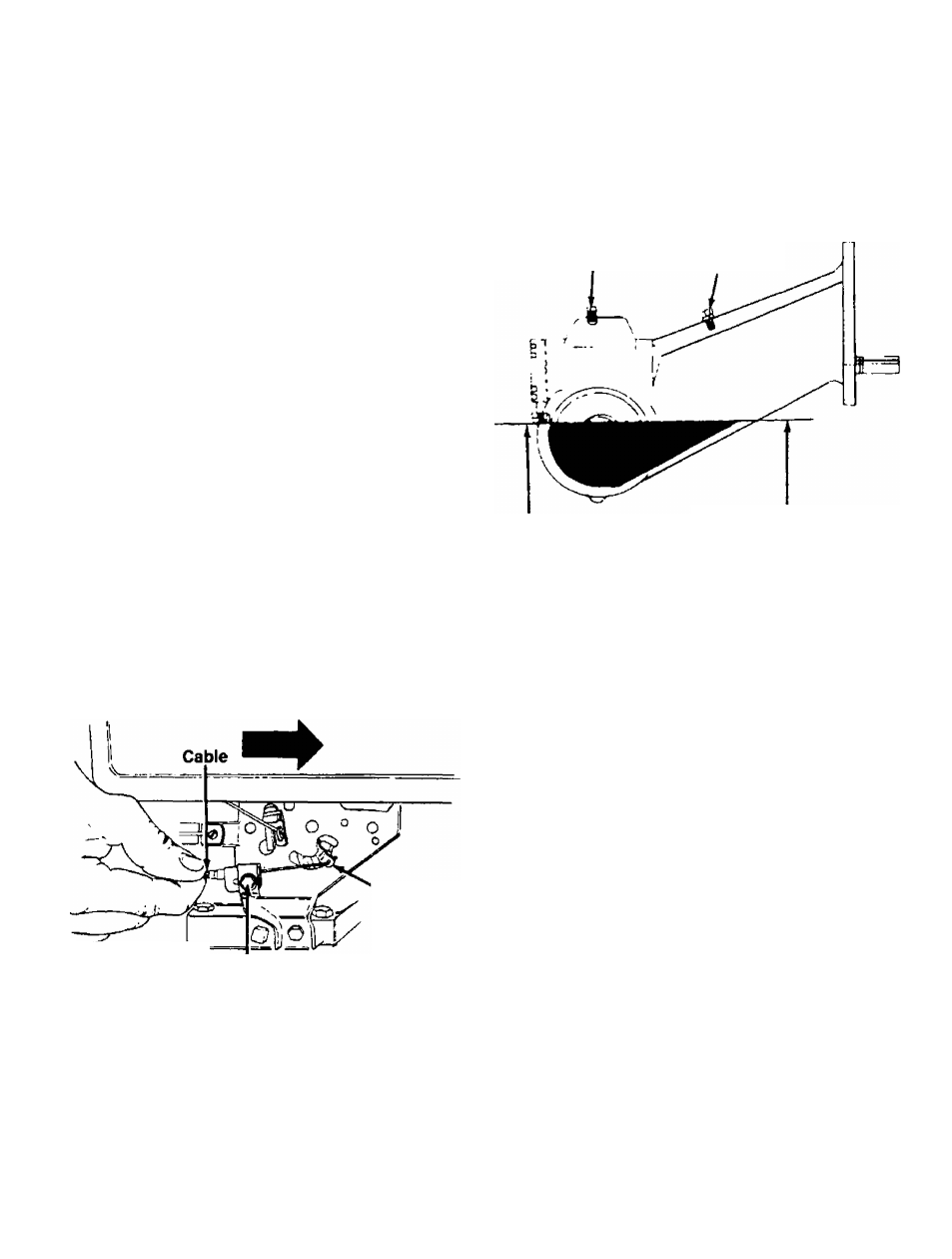

1. Loosen the cable clamp screw. See figure 28.

2. With the throttle control in FAST position and the

cable connected to the adapter lever, push the

cable through the cable clamp in the direction

shown in figure 28 until the adapter lever is as far

up as it will go.

3. Tighten the cable clamp screw.

4. Check that the engine stops when throttle control

is moved to STOP position. If engine does not stop,

loosen cable clamp screw and readjust by pulling

cable backward slightly until engine stops.

Retighten cable clamp screw.

Adapter

Lever

Cable Clamp

Screw

FIGURE 28.

LUBRICATION

A

; WARNING

Always stop engine and disconnect spark

plug wire before cleaning, lubricating

or doing any kind of work on tiller.

Pivot Points—Remove the belt cover and lubricate all

moving parts and pivot points at least once a season

using SAE 30 engine oil.

Transmission—Whenever disassembly of transmis

sion is required, transmission should be thoroughly

cleaned and lubricated with 6V2 ounces of PENNANT

OIL EP #35000 (available in an 8 ounces squeeze

tube). Order part no. 737-0136 through participating

Western Auto Stores. See figure 29.

Fill Plug

Breather Bolt

Oil Level

Check Plug

,5^

^

FIGURE 29.

MAINTENANCE

NOTE

Disconnect spark plug wire and ground

it against the engine before performing

any repairs or maintenance.

TROUBLE SHOOTING

Refer to page 21 of this manual for trouble shooting

information.

ENGINE

Refer to the engine section of this manual for all

engine maintenance instructions.

CLEANING THE TINE AREA

Clean the underside of the tine shield after each use.

The dirt washes off the tines easier if washed off im

mediately instead of after it dries.

TRANSMISSION

After first two hours of operation and every five hours

thereafter, remove the cotter pin from the bearing ad

justment cap. Screw the cap in as far as possible us

ing the handle of a pair of pliers or similar tool. Then

back it off V2 turn. See figure 30. Replace the cotter pin.

Start the tiller and engage the tines. If the engine stalls

out. the bearing adjustment cap should be unscrewed

slightly.

14