Engine, Lubrication, Air filter (see fig. 20) – Poulan 175668 User Manual

Page 13: Cooling system (see fig. 21), Customer responsibilities

Attention! The text in this document has been recognized automatically. To view the original document, you can use the "Original mode".

CUSTOMER RESPONSIBILITIES

A

Disconnect spark plug wire before performing any maintenance {except carburetor adjustment) to prevent

accidental starting of engine.

Prevent fires! Keep the engine free of grass, leaves, spiffed oif, or fuef. Remove fuel from tank before tipping unit

for maintenance. Clean muffler area of all grass, dirt, and debris.

Do not touch hot muffler or cylinder fins as contact may cause burns.

ENGINE

LUBRICATION

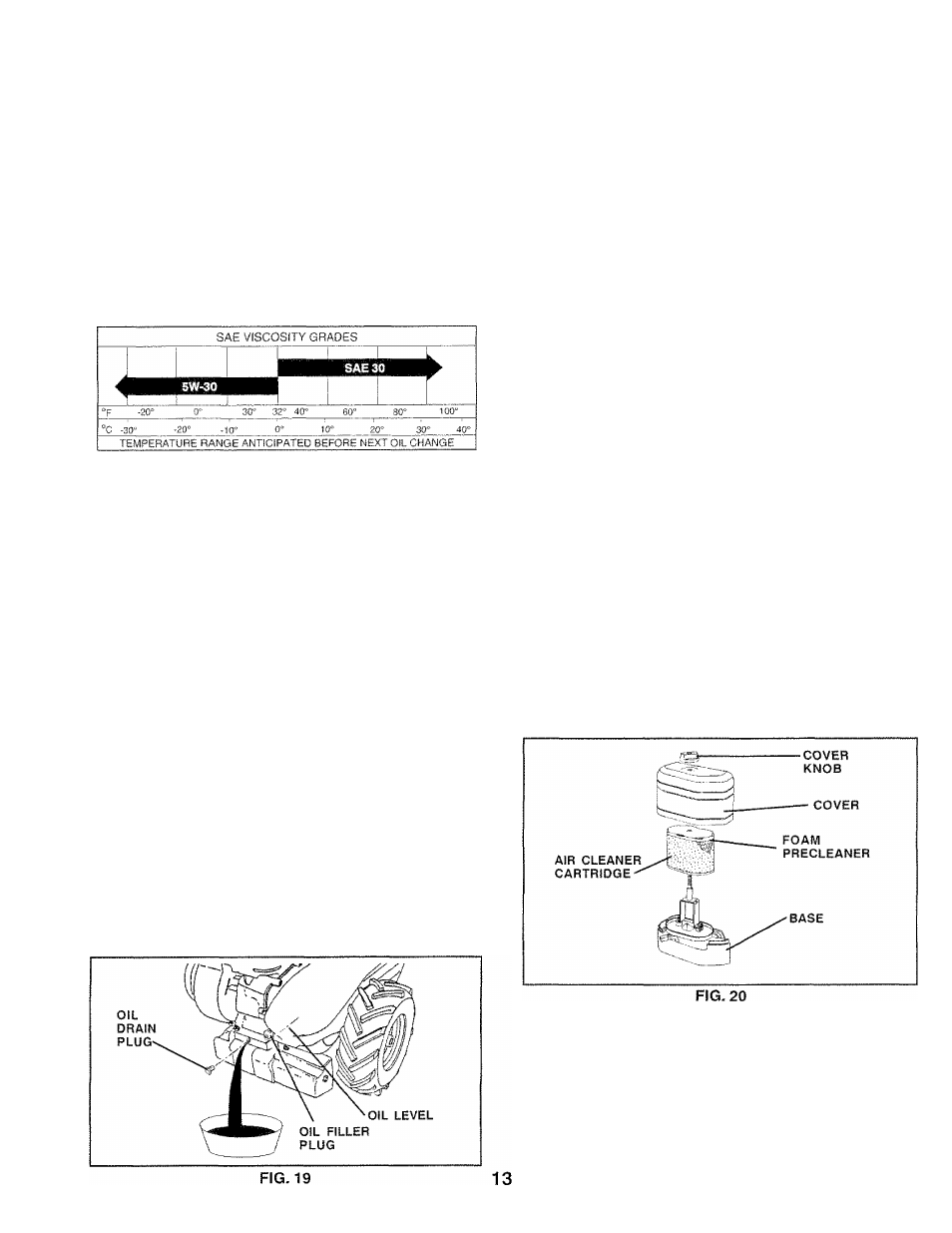

Use only high quality detergent oi! rated with API service

classification SF-SJ. Select the oil’s SAE viscosity grade

according to your expected temperature.

FIG. 18

NOTE: Although multi-viscosity oils (5W-30,10W-30, etc.)

improve starting in cold weather, these multi-viscosity oils

will result in increased oil consumption when used above

32°F (0°C). Check your engine oil level more frequently to

avoid possible engine damage from running low on oil.

Change the oil after every 25 hours of operation or at least

once a year if the tiller is not used for 25 hours in one year.

Check the crankcase oil level before starting the engine and

after each five (5) hours of continuous use. Add SAE 30

motor oil or equivalent. Tighten oil filler plug securely each

time you check the oi! level.

TO CHANGE ENGINE OIL (See Figs. 18 and 19)

Determine temperature range expected before oil change.

Ail oil must meet API service classification SF-SJ.

•

Be sure tiller is on level surface.

•

Oil will drain more freely when warm.

•

Use a funnel to prevent oil spill on tiller, and catch oil in

a suitable container.

•

Remove drain plug.

•

Tip tiller forward to drain oil.

•

After oil has drained completely, replace oil drain plug

and tighten securely,

•

Remove oil filler plug. Be careful nottoallowdirtio enter

the engine.

•

Refill engine with oil. See “CHECK ENGINE OIL LEVEL”

in the Operation section of this manual.

AIR FILTER (See Fig. 20)

Your engine will not run properly using a dirty airfiiter. Clean

the foam pre-cleaner after every 25 hours of operation or

every season. Service paper cartridge every

100 hours of

operation or every season, whichever occurs first.

Service air cleaner more often under dusty conditions.

•

Remove cover screw and cover.

TO SERVICE PRE-CLEANER

•

Remove foam pre-cieaner from air cleaner cover.

•

Wash it in liquid detergent and water.

•

Squeeze It dry in a clean cloth.

•

If very dirty or damaged, replace pre-cleaner.

•

Reinstall pre-cleaner into air cleaner cover.

•

Reinstall cover and secure screw.

TO SERVICE CARTRIDGE

•

Carefully remove cartridge to prevent debris from enter

ing carburetor. Clean base carefully to prevent debris

from entering carburetor.

•

Clean cartridge bytapping gently on flat surface, if very

dirty or damaged, replace cartridge,

•

Reinstall cartridge, cover with pre-cleaner and secure

with screw.

IMPORTANT:

PETROLEUM SOLVENTS, SUCH AS

KEROSENE, ARE NOT TO BE USED TO CLEAN THE

CARTRIDGE. THEY MAY CAUSE DETERIORATION OF

THE CARTRIDGE. DO NOT OIL CARTRIDGE. DO NOT

USE PRESSURIZED AIR TO CLEAN OR DRY

CARTRIDGE.

COOLING SYSTEM (See Fig. 21)

Your engine is air cooled. For proper engine performance

and long life keep your engine clean.

•

Clean air screen frequently using a stiff-bristled brush.

•

Remove blower housing and clean as necessary,

•

Keep cylinder fins free of dirt and chaff.