To regulate the length of stitch, Reverse sewing, To regulate the stitch formation – SINGER W217 User Manual

Page 8: Flfl. 16, To regulate the needle tension, 10 to regulate the stitch formation

Attention! The text in this document has been recognized automatically. To view the original document, you can use the "Original mode".

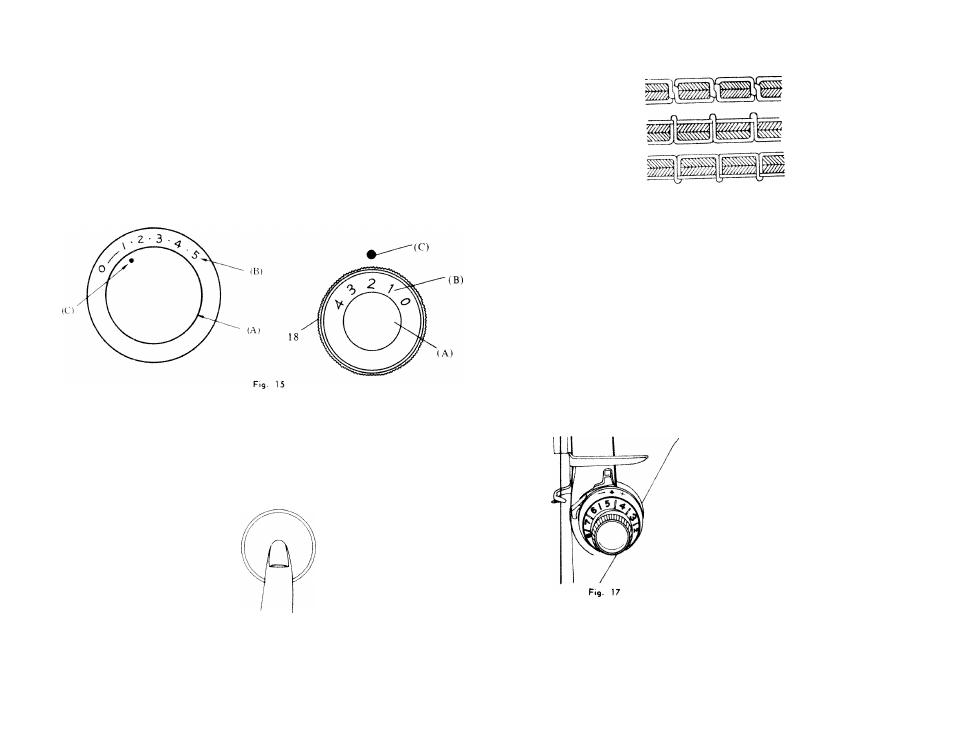

TO REGULATE THE LENGTH OF STITCH

The

"STITCH

REGULATOR

DIAL"

(18)

mokes

it

possible

to

obtain

different

stitch lengths by a simple turn. Numbers (Bi around the dial lAI and the

Indicotor vC) ore your stitch length guides. The higher the number the

longer the stitch. For heovier materials, use the high numbers. For silks,

nylons and thin moteriols, use the low numbers.

To regulate the stitch, turn the Dial (A) until the Indicator ¡C

stitch length you wont.

if too close to 0, the machine will not feed ot o

in one spot.

NEVER SEW OR USE THE MACHINE

IN ZERO POSITION

points to the

and wilt continue sewing

REVERSE SEWING

The stitch regulator dial (A) is also used to stitch in reverse.

When reverse stitching is wanted for tacking seams, push the Reverse button

(A) in until it stops. The stitch length will remain ttie same because this is

controlled by ttre mechanism.

10

TO REGULATE THE STITCH FORMATION

(A)

( B)

(C)

Flfl. 16

For perfect stitching, the tension on the upper ond under threads should be

equal and just sufficiently strong to lock both threads in the centre of the

moteriols os shown above (A).

If the tension of the needle threod is too tight, or if that of the bobbin thread

too loose, the needle threod will lie straight along the upper surfoce of the

moterial, thus moking on imperfect stitch, os shown in (B).

if the tension of the bobbin threod is too tight, or if that of the needle is too

loose, the bobbin threod will be stroight olong the under side of the materiol,

thus making on imperfect stitch, os shown above (C).

N o t e :

Be sure to uso the threod suitable to the material. (See page 4)

TO REGULATE THE NEEDLE TENSION

A correct stitch ccn usually be obtained by varying the tension on the needle

threod.

All adjustments should be made while

the presser foot is down since an

releose does not permit odjustments

to be made while the presser foot

is up.

To increose the tension, turn the thumb nut

on the tension dial (7) clockwise. To

decrease the tension, turn the nut in the

opposite direction. The thumb nut should

not be turned abruptly but regulated little

by little until the desired tension is ob-

toined.

The quality of sewing depends on the ten

sion of thread. Hence, it is necessary for the user to become fully fomiliar

with the correct tensions through proctice.

^

11