Winding the iobbin, How to wind the bobbin evenly, Neidli and thread never – SINGER W217 User Manual

Page 5

Attention! The text in this document has been recognized automatically. To view the original document, you can use the "Original mode".

NEiDLI AND THREAD

Never

use

a benf needle, nor cxie with o blunt point, since this couses imper

fect stiJehes ond moy couse the needle to breok.

Unless the needle is in

CLEAR

TO

THE

TOP,

FLAT

SIDE

TOWARD

THE

BALANCE

WHEEL,

the

machine will be out of "time", ond skipped or imperfect stitches will result

end needles moy break.

The size of the needle should conform- to the size of the thread ond both should

be suiloble to the material. Use a needle sufficiently lorge to permit the

threod to poss freely through the eye. In general sewing, use the some size

threod in the bobbin as used on top. For detoiled informotion consult follow

ing chort,

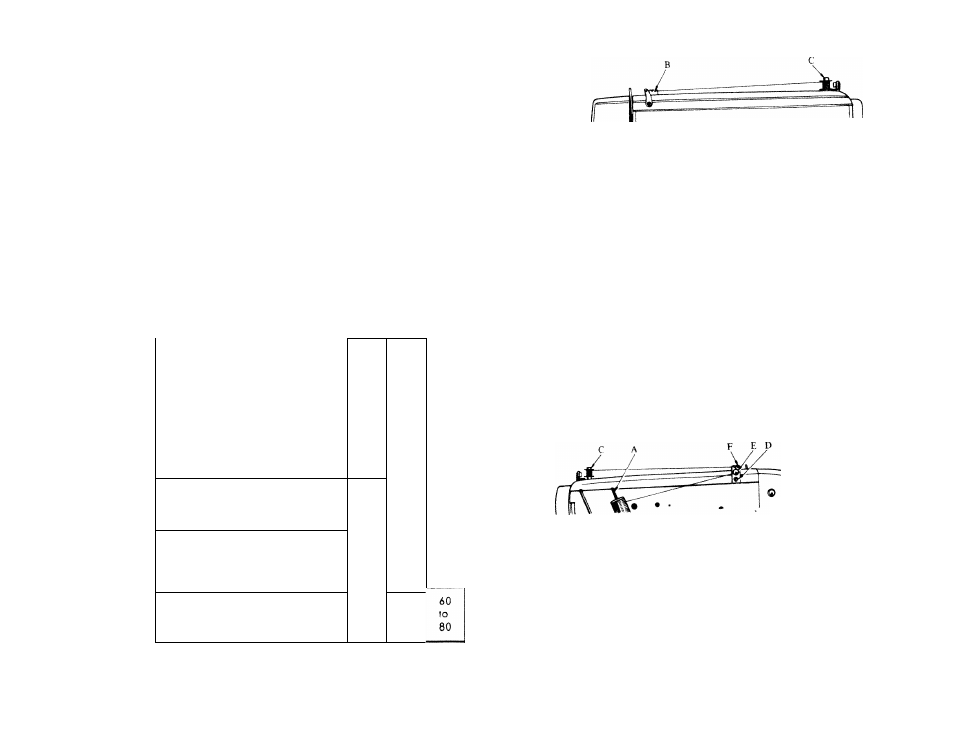

NEEDLE AND THREAD SIZES (USE 1 5 x 1 NEEDLE ONLY) CHART

Sizes & Grades

of Needles

( Medium-Fine)

14

(Medium )

16

( Light. Heovy)

18

(Medium-

Heavy)

19

(Heovy)

Type of Fobric

ond

“ ..........

Work to be Done

Cotton

Silk

M edium light.weight & sum m ertim e fobnes.

For house dresses. children's dresses

80

to

100

0

woshoble cotton dress, oprons, light-weight

cur tom s.

Twist

Dress silks ond coM on. iighl-weight woolens,

draperies, fobric furnishings. For genero!

60

to

80

A & B

household sewing, fine m en’s shuts, sm ocks,

window droperies and fobric decorations.

Twist

Heavy cretonne, m odros, m usfm , brocodes

40

C

and, qu’lts.

For m en’s work shirts, sm ocks ond oprons.

heovy quilling ond fobne furnishings.

60

Twist

Heavy woven cooling, light-weight convos.

bed ticking, upholstery ond owning m ote-

30

D

rials, slipcover fobrics.

For work or sports uniform s, suits m ode

of strong linen or cotton fobrics. ownm g

40

Twist

slip covers ond m ottresses.

______

Heavy woven suiting, coating duck, tick,

ing. drilling, convos and socking, for heovy

10

to

30

E

wash uniform s, bedding supplies for hospi-

lois ond com ps.

Twist

SIZE OF THREAD

Linen

WINDING THE iOBBIN

Fig. 5-A

1,

Hold the balance wheel (20) with your left hand, and with your right hand loosen

the stop motion knob (19) by turning it toward you. You can now turn the

balance wheel without the needle bar and other sewing mechanism moving.

2 Place the bobbin on the bobbin winder spindle (C) and push it down firmly. Press

the bobbin winder spindle (C) to right until a "Click" is heard. This engages the

bobbin winder with the balance wheel.

3, Place a spool of therad on the spool pin (A), run the thread under the tension

disc

(E) and then through the left slot of thread guide (B) and back to the bobbin on the

spindle.

4 Bun the end of the thread through any hole in the top side of the bobbin from the

inside out, leaving 3 to 4 inches of thread projecting from the bobbin. Thread

should not be allowed to catch over the edge of the bobbin.

5.

Now, you can operate the machine as in ordinary sewing and the thread will be

wound. Operate the machine slowly to wind the bobbin evenly.

6.

The loose end of the thread which is threaded through the hole in the bobbin should

be held by hand until a few coils are wound. Then break off the loose end.

7.

When the bobbin is completely wound, stop the machine and press the bobbin

winder spindle (C) to left so that the bobbin winder disengages the balance wheel.

Do not wind the bobbin so full that the thread extends beyond the sides of the

bobbin.

8. Break off the thread, and remove the bobbin.

9.

Hold the balance wheel with your left hand and with your right hand tighten the

stop motion knob by turning it away from you. (See Figs. 5-A, 5-B & 5-C)

HOW TO WIND THE BOBBIN EVENLY

Rear

view

of machine

i'

Fig. 5-B

To correct uneven winding of the bobbin, proceed as follows.

1. If more thread winds at the top of the bobbin, loosen screw (D) and shift thread

guide (£) siightiy downward.

Repeat as necessary until bobbin winds evenly. (Fig. 5-B).

2. If more thread winds at the bottom of the bobbin, loosen screw (D) and shift

thread guide (E) slightly upward.

Repeat as necessary until bobbin winds evenly. (Fig. 5-B).

3. When winding the bobbin, be sure that the thread goes under the tension disc and

through right slot (F), and then to the bobbin winder. (Fig. 5-C).

Not* : This machine uses standard 15 class bobbin.

Fig. 5-C

5

-