Satin stitching, Accessory and selector settings, Adjusting stitch length – SINGER 4314 User Manual

Page 23: Adjusting needle thread tension

Attention! The text in this document has been recognized automatically. To view the original document, you can use the "Original mode".

satin stitching

When

you

wish

to

produce

a

satin

stitch

make

a

test

sample

first

so

you

can

adjust

stitch

length

and

thread

tension

properly.

Soft

fabric

may

require

a

backing

to

ensure

a

firm

stitch.

Crisp

organdy,

lawn

or

a

fusible

interfacing

are suitable for this purpose.

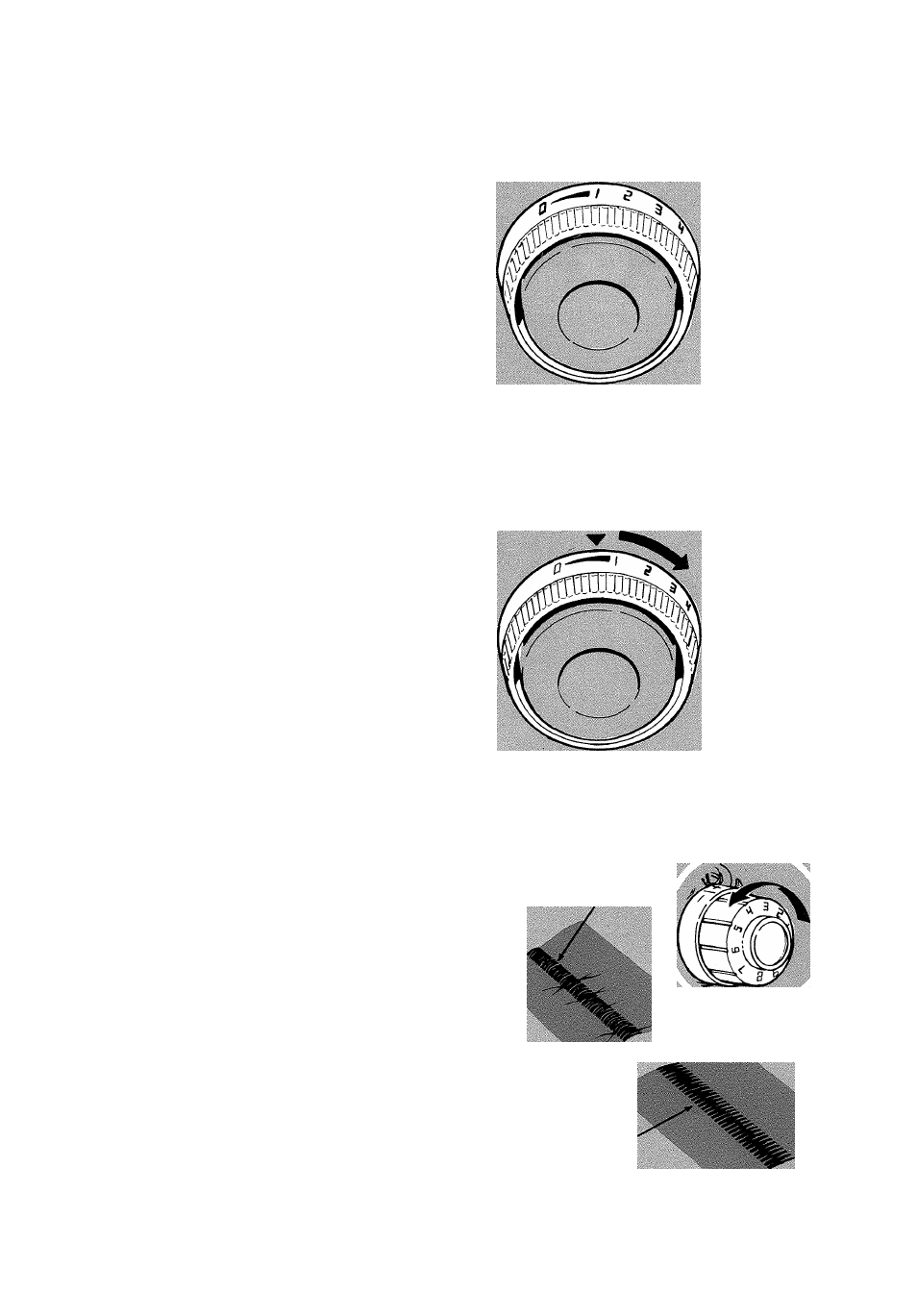

Accessory and Selector Settings

• Pattern Group Selector:

1

• Needle Position: L.

• Stitch Width: -4'«

aa

AAA

i

0 ; . . . 2 . . , 3 . ¡ 1 .

• Stitch Length: 0 to 1

General Purpose Needle Plate

Special Purpose Foot

* •

ADJUSTING STITCH LENGTH

• Turn stitch length selector dial to

1.

•

Run the machine at a slow speed and grad

ually

turn

stitch

length

dial

clockwise

until

stitches

are

closely

spaced

and

form

a

smooth surface.

ADJUSTING NEEDLE THREAD TENSION

Satin

stitching

requires

less

tension

than

straight

stitching

or

open

zig-zag

stitching.

Furthermore,

the

wider

the

stitch,

the

lighter

the

tension

on

the

thread

must

be.

Notice

the

stitching on your sample. If the fabric is puck

ered,

lower

the

needle

thread

tension

by

turning the tension dial to a lower number.

Incorrect

Correct

2 l