Adjusting bobbin-thread tension – SINGER 5102 User Manual

Page 15

Attention! The text in this document has been recognized automatically. To view the original document, you can use the "Original mode".

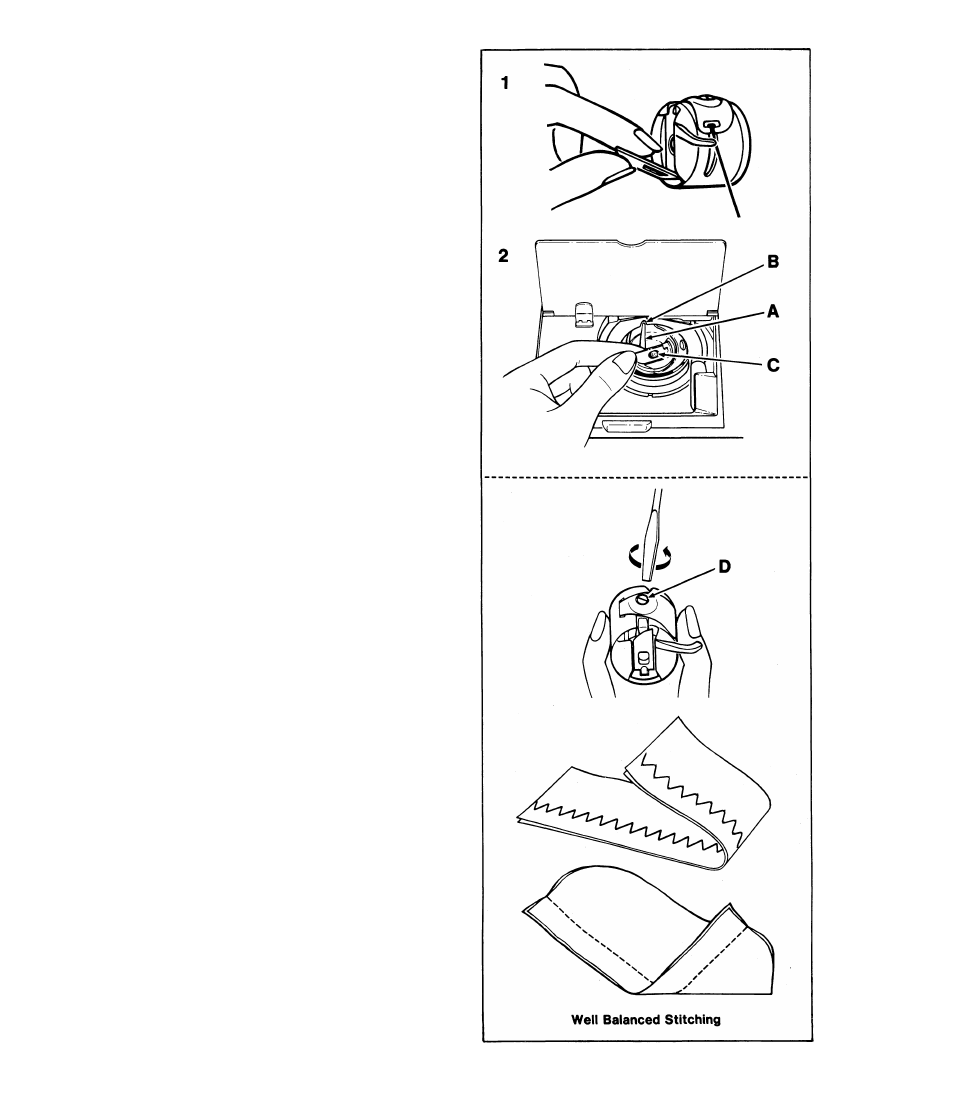

REPLACING THE BOBBIN CASE

1. Hold bobbin case by latch, with about 7.5cm

(3 inches) of thread leading off top of case.

2. Align protruding finger A with slot B and

slide case on to stud C.

• Release the latch and push case until it

clicks into place. Allow 7.5cm (3 inches) of

thread to hang free from bobbin case.

• Close cover plate. Be sure thread does not

get caught when cover plate is closed.

ADJUSTING BOBBIN-THREAD TENSION

The bobbin-thread tension has been set at the

factory for most types of stitching. You may

wish to adjust the bobbin-thread tension when

straight stitching on fine fabrics or to balance

an open zig-zag stitch. Bobbin and needle

threads lock at the corner of each stitch when a

zig-zag stitch is balanced. To adjust the bob-

bin-thread tension, follow the procedure below

using two layers of scrap fabric.

• Raise the presser foot.

• Raise needle to highest position by turning

the hand wheel toward you.

• Open cover plate and remove the bobbin

case as instructed on page 12.

• Slowly turn screw D to the left, using the

small screwdriver in your accessory box,

until desired stitch appearance is reached.

• When stitching is completed, turn screw D to

the right, back to original position, for all

other sewing.

13