SINGER 95-100 User Manual

Page 5

Attention! The text in this document has been recognized automatically. To view the original document, you can use the "Original mode".

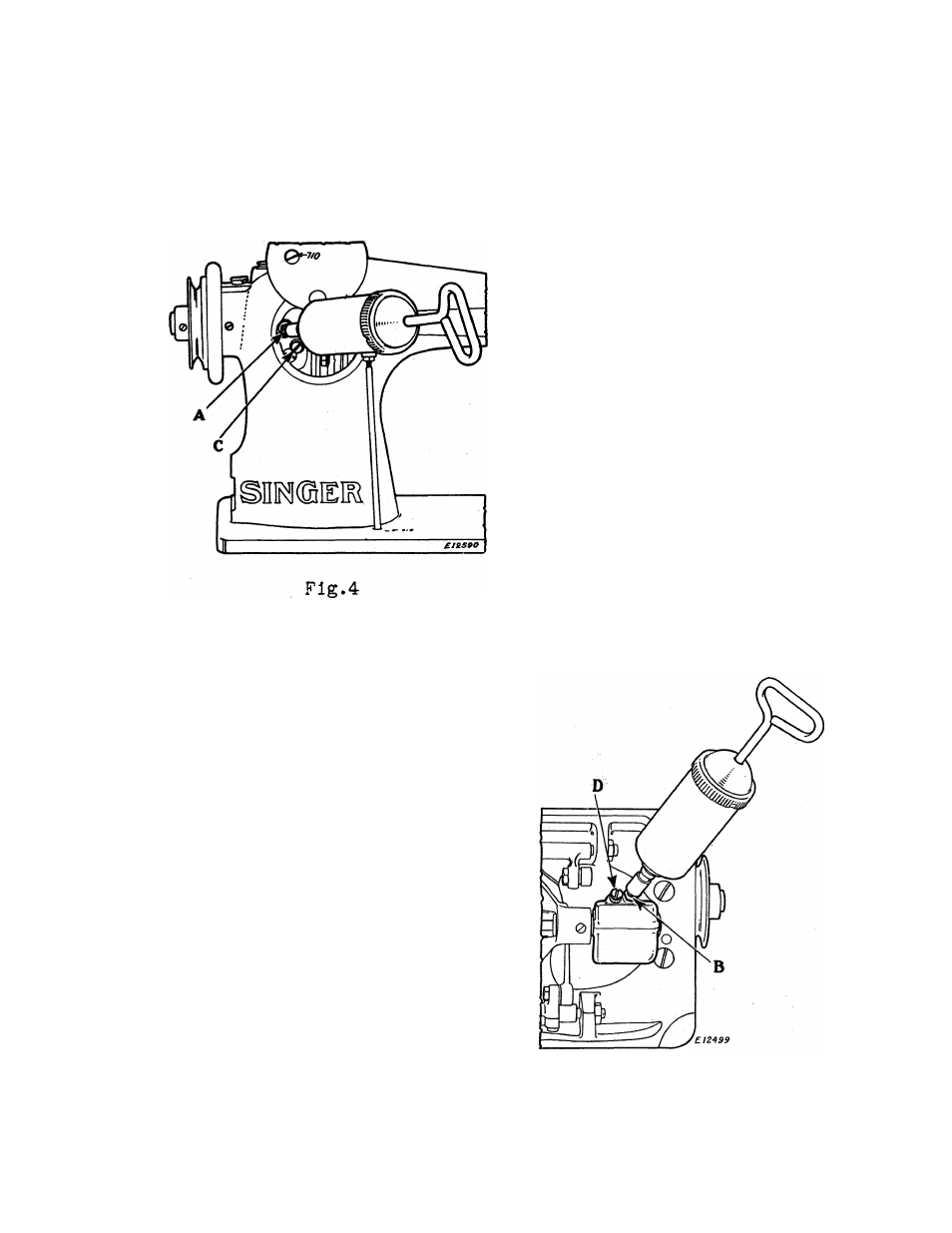

use GEAR LUBRICANT in the gear cases of these machines.

When the machines leave the factory, the gear cases are packed

with sufficient GEAR LUBRICANT for approximately 160 hours of

of operatlcm.

Replenish the gear cases

at (A) and (B), Figs. 4 and 5

with GEAR UJBRICANT every 160

hours of opérât im.

Alemlte

Grease

Guns,

SINGER NO. 121587 (3 oz. ca

pacity) or SINGER NO. 121588

(1/2 Ih. capacity) provide the

most ccxivenlent means of apply

ing GEAR LUBRICANT to the

gears.

To supply grease to the

upper gear case (Flg.4), have

the machine In its normal

working position, remove the

level hole screw (C,Fig.4) and force the lubricant into the Ale

mlte

fitting

(A,Fig.4)

until

it emerges from the level hole

at (C), then replace the screw

(C).

To supply grease to the

lower gear case (Fig.5), lay

the machine back on the table,

remove the level hole screw

(D,Fig.5) and force the lubri

cant into the Alemlte fitting

(B,Fig.5)

until

it

emerges

from the level hole at (D),

then replace the screw (D).

Flg.5.

CAUTION - To avoid overfilling of the gear cases, do. not turn

the balance vheel when grease is being applied through the Alemlte

fittings.