SINGER 95-100 User Manual

Page 15

Attention! The text in this document has been recognized automatically. To view the original document, you can use the "Original mode".

13

Tensions

For ordinary stitching, the needle and bobbin threads should

be locked in the center of the thickness of the material, thus:

Fig.17. Perfect Stitch

If the tension on the needle thread Is too tight, or If that

on the bobbin thread Is too loose, the needle thread will lie

straight along the upper surface of the mterlal, thus:

Fig.18. Tight Needle Thread Tension

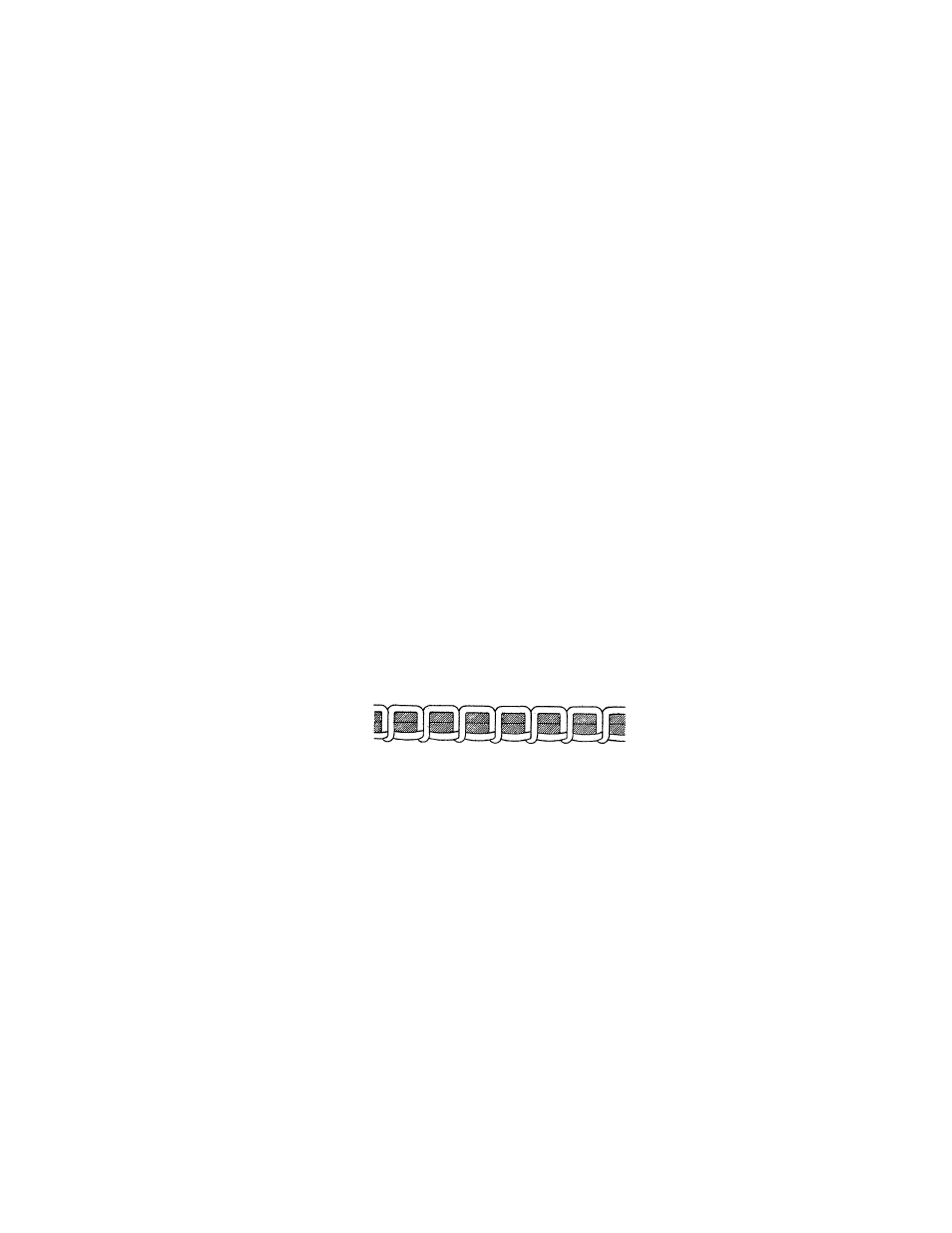

If the tension on the bobbin thread is too tight, or If that

on the needle thread Is too loose, the bobbin thread will lie

straight along the under side of the material, thus:

Fig.19. Loose Needle Thread Tension

To Regulate the Tensions

THE TENSION ON THE NEEDLE THREAD SHOULD BE REGULATED ONLY

WHEN THE PRESSER FOOT IS DOWN. Having lowered the presser foot,

turn the small thumb nut (C,Flg.2), at the front of the tension

discs, over to the right to Increase the tension. To decrease

the tension, turn this thumb nut over to the left.

The tension on the bobbin thread Is regulated by the large

screw (FF,Fig.ll) In the tension spring on the outside of the

bobbin case. To increase the tension, turn this screw over to

the right. To decrease the tension, turn this screw over to the

left.

When the tension on the bobbin thread has been once properly

adjusted. It Is seldom necessary to change It, as a correct stitch

can usually be obtained by varying the tension on the needle

thread.