Grooving, fluting, and veining, End cutting using the fence with the push block – Sears 26462_0 User Manual

Page 16

Attention! The text in this document has been recognized automatically. To view the original document, you can use the "Original mode".

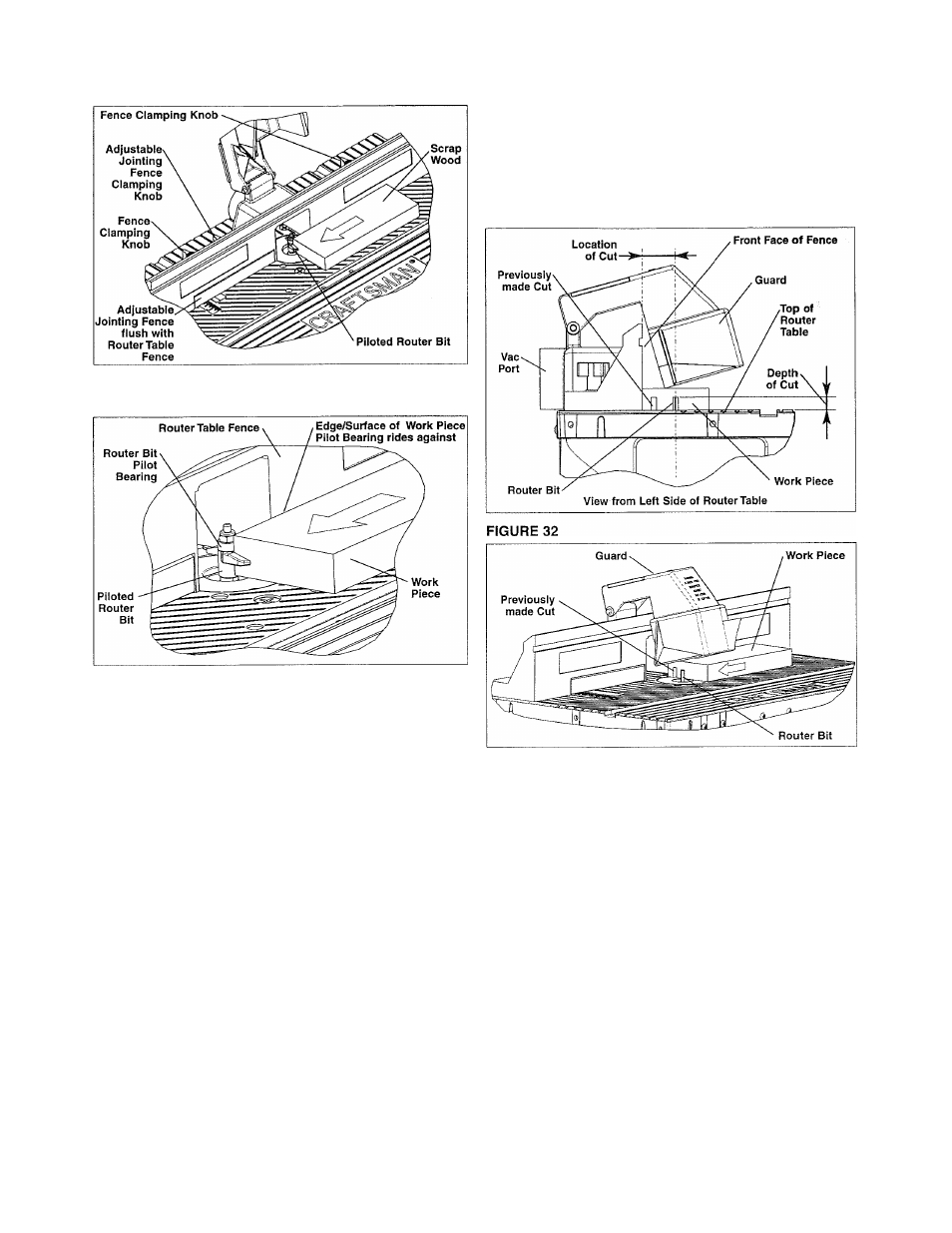

FIGURE 29

NOTE

Overhead guard shown raised for reasons of clarity.

FIGURE 30

NOTE

Test cut a scrap piece of wood

When routing deep cuts (controlled

by the router bit) in a work piece, remove material in

increments to prevent your router from overloading.

Repeat operation with several passes until the desired

depth is achieved.

FIGURE 31

Overhead guard shown raised for reasons of clarity.

GROOVING, FLUTING, AND VEINING:

Always UNPLUG the router before making any settings

or adjustments, or changing bits.

When routing, aiways feed AGAINST the rotation of

the cutter. Feed work piece in the direction of the

arrow in Figure 32.

For maximum accuracy, one edge of your work piece

(edge sliding against fence) must be true and straight.

Set up your fence as follows:

1. Position the fence behind the router bit for the

desired cutting depth (the distance of the cut from the

edge of the work piece, as shown in Figure 31). Make

sure the overhead guard is in place.

2. SECURELY TIGHTEN both fence clamping knobs.

3. Make the cut by sliding the straight edge of the

work piece against the fence, as shown in Figure 32.

(For each successive cut, the fence wiil need to be

adjusted.)

END CUTTING USING THE FENCE WITH THE

PUSH BLOCK

A

warning

End cutting is performed with the

overhead guard rotated back so that it does not cover

the router bit. Therefore, EXTREME CARE must be

taken when end cutting so that fingers, hands, or any

other parts of your body DO NOT contact the bit, which

could result in serious bodily injury.

When routing on the ends of a work piece for making

tenons, siiding dovetails, and tongue and groove joints,

the work piece must be made smooth with both the

edges and the ends made true to each other and its

surfaces. All surfaces must be square, or at 90c<> with

each other.

NOTE

before making your finished cut.

The push block and clamp plate

assembly will not accommodate work pieces wider

than 4".

16