Warning, Final check, М2т1 – Sears N8MPL050B12B1 User Manual

Page 20

Attention! The text in this document has been recognized automatically. To view the original document, you can use the "Original mode".

2. Follow steps 2 through 4 Piping with Street Elbows.

1.

Screw one elbow onto gas valve with the outlet facing away

from the furnace.

2.

Screw second elbow onto first elbow tight enough to be leak

proof. An additional V

4 turn will be required at the end of step

2. See Figure 17 and Figure 18.

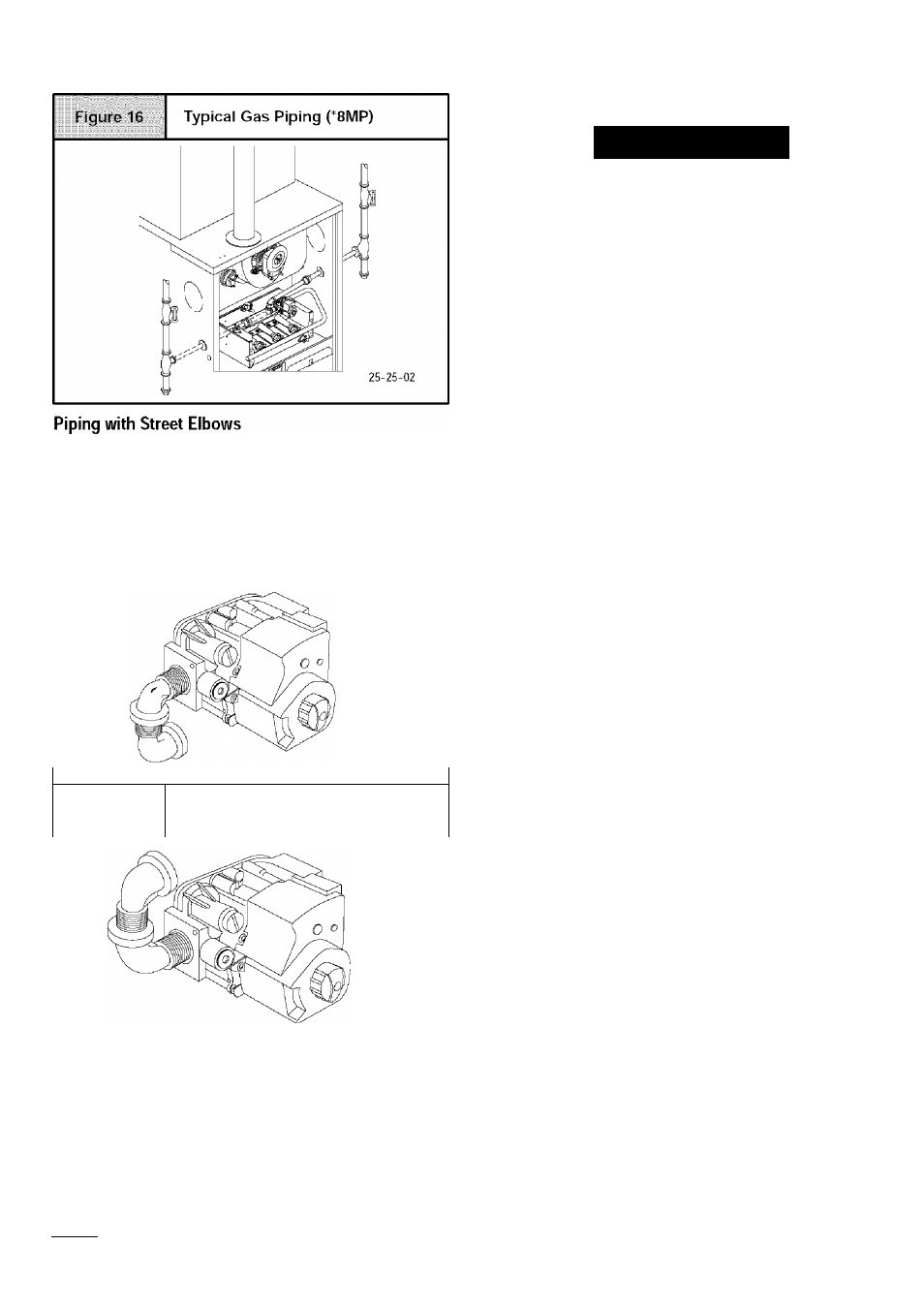

Figure 17

Gas Valve with Elbows (*8MP)

25-25-03

Figure 18

Gas Valve with Elbows (*8MP)

3. Gas supply line then can be run directly into opening of elbow.

Piping with Close Nipples and Standard Elbows

1. Assemble elbows and nipples similar to street elbows shown

in Figure 13.

WARNING

FIRE OR EXPLOSION HAZARD.

Failure to properly install metal gas connector could

result in death, personal injury and/or property

damage.

A flexible corrugated metal gas connector must be

properly installed, shall not extend through the side

of the furnace, and shall not be used inside the

furnace.

Black iron pipe shall be installed at the furnace gas

control valve and extend a minimum of 2" outside

furnace.

Additional LP Piping Requirements

•

Have a licensed LP gas dealer make all connections at stor

age tank and check all connections from tank to furnace.

•

If copper tubing is used, it MUST comply with limitation set in

Local Codes, or in the absence of local codes, the gas codes

of the country having jurisdiction.

•

Two-stage regulation of LP gas is recommended.

wmrnm

FIRE OR EXPLOSION HAZARD.

An open flame or spark could result in death,

personal injury and/or property damage.

Liquefied petroleum (LP) gas is heavier than air and

will settle and remain in low areas and open

depressions.

Thoroughly ventilate area and dissipate gas. Do

NOT use a match or open flame to test for leaks, or

attempt to start up furnace before thoroughly

ventilating area.

Final Check

•

Test all pipe for leaks.

•

If orifices were changed, make sure they are checked for

leaks.

•

During pressure testing of gas supply piping system:

a. If test pressure does not exceed V

2" psi, isolate the

furnace from the gas supply piping system by closing the

equipment shutoff valve.

b. If test pressure exceeds V

2" psi, the furnace and its manual

equipment shutoff valve must be disconnected from the gas

supply piping system.

•

To check for leaks apply soap suds or a liquid detergent to

each Joint. Bubbles forming indicate a leak.

•

Do not use an open flame to test for gas leaks. Fire or explo

sion could occur.

•

Correct even the smallest leak at once.

М2Т1

441 01 2613 02

- N8MPL075B12B1 8MPL050B12B1 N8MPN100J22B1 N8MPL125J20B1 8MPL075F16B1 N8MPN100F14B1 N8MPL100J22B1 8MPN125J20B1 N8MPN075F16B1 8MPN075B12B1 N8MPN125J22B1 8MPN100F14B1 8MPN100F20B1 N8MPN125J20B1 N8MPL100F20B1 8MPL075B12B1 8MPL125J20B1 N8MPN050B12B1 8MPN050B12B1 N8MPL125J22B1 8MPN075F16B1 8MPN150J20B1 8MPN100J20B1 N8MPN075B12B1 N8MPL075F16B1 8MPL100F20B1 N8MPN100F20B1 8MPL100J20B1