Warning, Rì9l – Sears N8MPL050B12B1 User Manual

Page 19

Attention! The text in this document has been recognized automatically. To view the original document, you can use the "Original mode".

5.

Use ground joint unions and install a drip leg no less than 3 "

long to trap dirt and moisture before it can enter gas control

valve inside furnace.

6.

Provide a Vg" NPT pluggedtappingfortestgaugeconnection

immediately up stream of gas supply connection to furnace.

7.

Use two pipe wrenches when making connections to prevent

furnace gas control valve from turning.

NOTE: If local codes allow the use of a flexible gas appliance con

nector, always use a new listed connector. Do not use a connector

which has previously served another gas appliance.

8.

Flexible corrugated metal gas connector may

NOT

be used

inside the furnace or be secured or supported by the furnace

or ductwork.

9.

Properly size gas pipe to handle combined appliance load or

run gas pipe directly from gas meter or LP gas regulator.

10. Install correct pipe size for run length and furnace rating.

11. Measure pipe length from gas meter or LP second stage regu

lator to determine gas pipe size.

Right Side Gas Supply Piping (N8MP)

Gas line can be installed directly to the gas valve through the hole

provided in the right side of the cabinet. See Figure 12

Left Side Gas Supply Piping (N8MP)

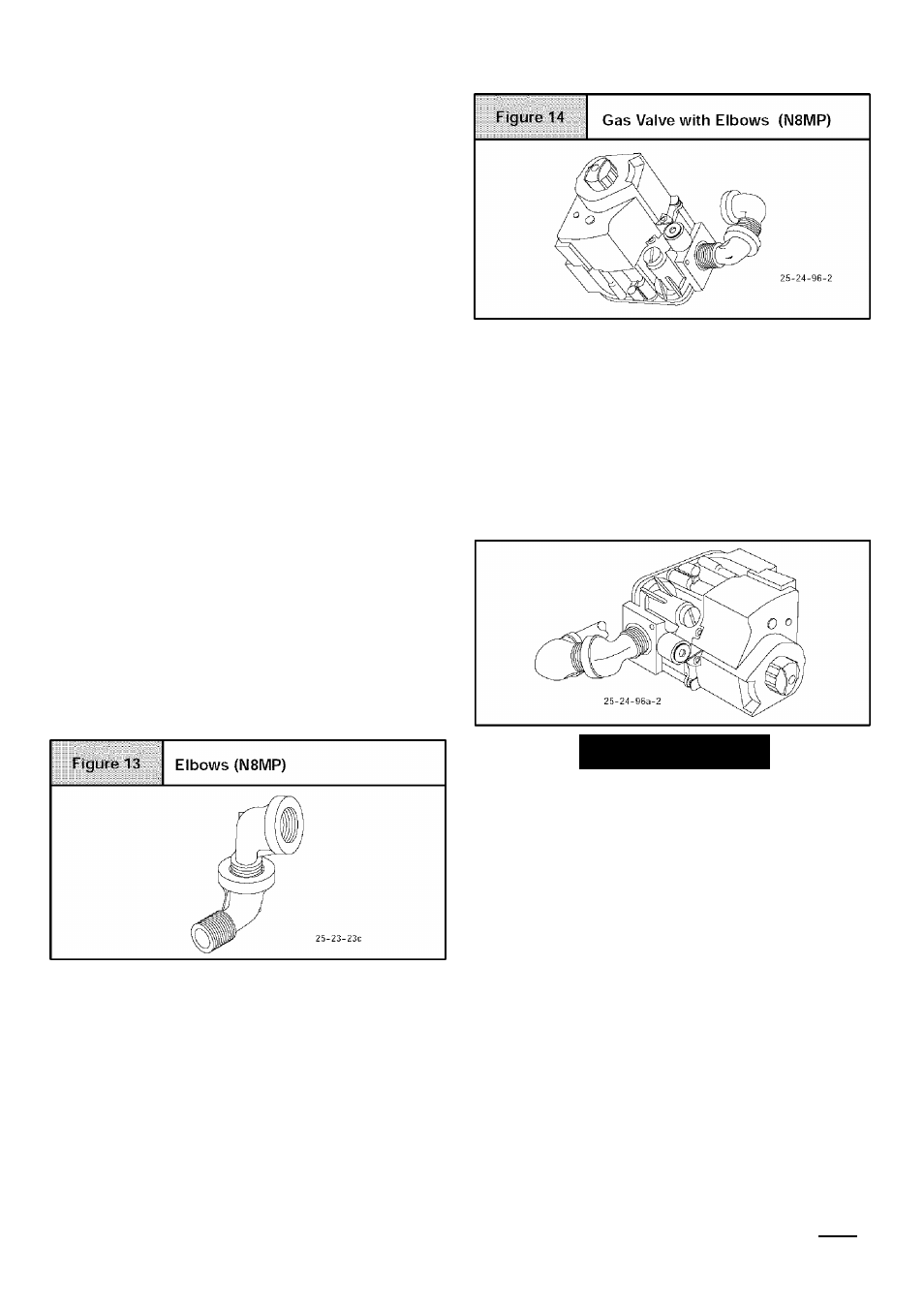

Two(2) 90° street elbows or two(2) 90° standard elbows and

two(2) close nipples are required for left side gas supply. See

Figure 12.

Piping with Street Elbows

1.

Assemble the elbows so that the outlet of one(1) elbow is 90°

from the inlet of the other. The elbows should be tight enough

to be leak proof. An additional V

4 turn will be required at the

end of step 2, see Figure 13.

Screw elbow assembly into gas valve far enough to be leak

proof. Position elbow assembly so that the inlet of the elbow is

at the top of the gas valve. An additional % turn will be re

quired in step 3. Turn open end of inlet elbow to face the left

side of the furnace

( V 4

turn), see Figure 14.

3.

Turn assembly an additional

^/9 turn to position inlet near the

bottom back corner of the gas valve in line with gas opening

on left side of furnace, see Figure 15.

4.

Gas supply line then can be run directly into opening of elbow.

Piping with Close Nipples and Standard Elbows

1.

Assemble elbows and nipples similar to street elbows shown

in Figure 13.

2.

Follow steps 2 through 4 Piping with Street Eibows.

Figure 15 Gas Valve with Elbows (N8MP)

WARNING

FIRE HAZARD

Failure to follow safety warnings exactly could

result in death, personal injury and/or property

damage.

Use wrench to hold furnace gas control valve when

turning eibows and gas line to prevent damage to

the gas control valve and furnace.

Left Side Gas Entry (*8MP) (See Figure 16)

Pipe can be run directly to gas valve through the hole provided in

the left side of the cabinet.

Right Side Gas Entry (*8WIP) (See Figure 16)

Two (2) 90° street elbows or two (2) 90° standard elbows and two

(

2) close nipples are required for right side gas supply.

441 01 2613 02

rÌ9l

- N8MPL075B12B1 8MPL050B12B1 N8MPN100J22B1 N8MPL125J20B1 8MPL075F16B1 N8MPN100F14B1 N8MPL100J22B1 8MPN125J20B1 N8MPN075F16B1 8MPN075B12B1 N8MPN125J22B1 8MPN100F14B1 8MPN100F20B1 N8MPN125J20B1 N8MPL100F20B1 8MPL075B12B1 8MPL125J20B1 N8MPN050B12B1 8MPN050B12B1 N8MPL125J22B1 8MPN075F16B1 8MPN150J20B1 8MPN100J20B1 N8MPN075B12B1 N8MPL075F16B1 8MPL100F20B1 N8MPN100F20B1 8MPL100J20B1