Maintenance, General recommendations, After first use – Sears 536.884821 User Manual

Page 15: As required, Snow thrower, Lubrication - every ten hours, Lubrication - not required, Maintenance -16, General recommenoatfons

Attention! The text in this document has been recognized automatically. To view the original document, you can use the "Original mode".

MAINTENANCE

GENERAL RECOMMENDATIONS

The warranty on this snow thrower does not cover items

that have been subiected to operator abuse or negli

gence, To receive full value from the warranty, operator

must maintain snowthroweras instaicted in this manual

Some adjustments will need to be made periodically to

properly maintain your snow thrower.

AH adjustments in the Service and Adjustments section of

this manual should be checked at least once each

season,

AFTER FIRST USE

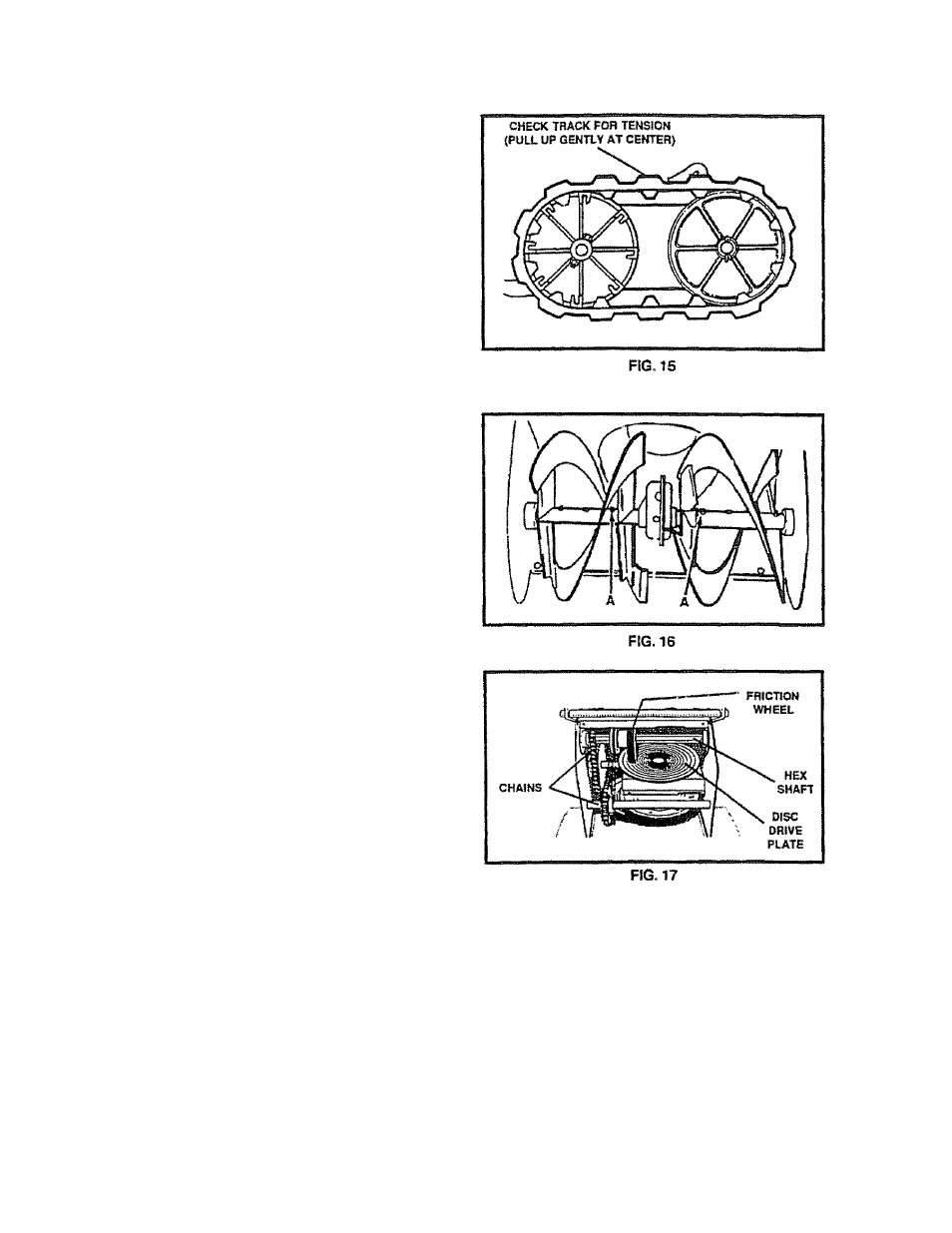

® Checklhetracksfortension and adjustif necessary

{See To Adjust Track paragraph on page 23)

Checkthe track adjustment and fasteners regularly,

® Be sure that all fasteners are tight,

AS REQUIRED

The following adjustments should be performed more

than once each season

&

Auger and Track Drive Belts should be adjusted

afterthe first 2 hours of use and again after 25 hours

and at the beginning of each season SeeTo Adjust

Beits paragraph on page 19

® AH screws and nuts should be checked often to

make sure they are tight, preferably after each use.

SNOW THROWER

LUBRICATION - EVERY TEN HOURS

@ Weight Transfer System - Coat weight transfer side

plates with clinging type grease, such as Lubriplate.

every ten ¡10) hours and before storage. See Lu

brication Chart on page 26,

m

Auger Shaft - Using a hand grease gun, lubricate the

auger shaft zerk fittings (See A, Fig, 16) every ten

(10) operating hours. Each time a shear bolt is

replaced ¡see To Replace Auger Shear Boll para

graph on page 23), the augershaft h/lUSTbegreased.

e For storage or when replacing shear bolts, remove

shear bolls and lubricate auger shalt zerks.. Rotate

augers several times on the shaft and reinstall Ihe

shear bolts.

LUBRICATION - NOT REQUIRED

e

Hex Shaft and Gears - Hex shaft and gears require

no lubrication, Allbearings and bushings are iileiime

lubricated and require no maintenance (See Fig 17).,

NOTE: Any greasing or oiling of the above components

can cause contamination of the Iriction wheel. If the disc

drive plate or friction wheel come in contact with grease

or oil, damage to the friction wheel will result

Should grease or oil come in contact with the disc drive

plate or friction wheel, be sure to clean the plate and

wheel thoroughly ,

NOTE: For storage, the hex shaft and gears should be

wiped with 10W-30 moior oil to prevent rusting (See Fig

17).

® Auger Gear Box - The auger gear box has been

factory lubricated for life. If for some reason lubri

cant should leak out, have auger gear case checked

by a competent repairman.

15