Carrier Puron 38EYA User Manual

Page 5

wrench an additional 1/12 turn (15 ft-lb). DO NOT OVER-

TIGHTEN.

REFRIGERANT TUBING AND FILTER DRIER

Installation of filter drier in liquid line is required.

Connect vapor tubing to fittings on outdoor unit vapor service

valves. Connect liquid tube to filter drier. (See Table 1 and Fig. 8.)

Use refrigerant grade tubing. Connect other end of filter drier to

adapter tube on liquid service valve.

SWEAT CONNECTION

To avoid valve damage while brazing, service valves must be

wrapped in a heat-sink material such as a wet cloth.

Wrap service valves and filter drier with a wet cloth or heat-

sinking material. Braze connections using either silver bearing or

non-silver bearing brazing material. Do not use soft solder

(materials which melt below 800°F.) Consult local code require-

ments.

LEAK CHECKING

Leak test all joints in indoor, outdoor, and refrigerant tubing.

EVACUATE REFRIGERANT TUBING AND INDOOR COIL

Never use the system compressor as a vacuum pump.

Refrigerant tubes and indoor coil should be evacuated using the

recommended deep vacuum method of 500 microns. The alternate

triple evacuation method may be used if the procedure outlined

below is followed.

IMPORTANT:

Never open system under vacuum to atmosphere

without first breaking it open with nitrogen.

Deep Vacuum Method

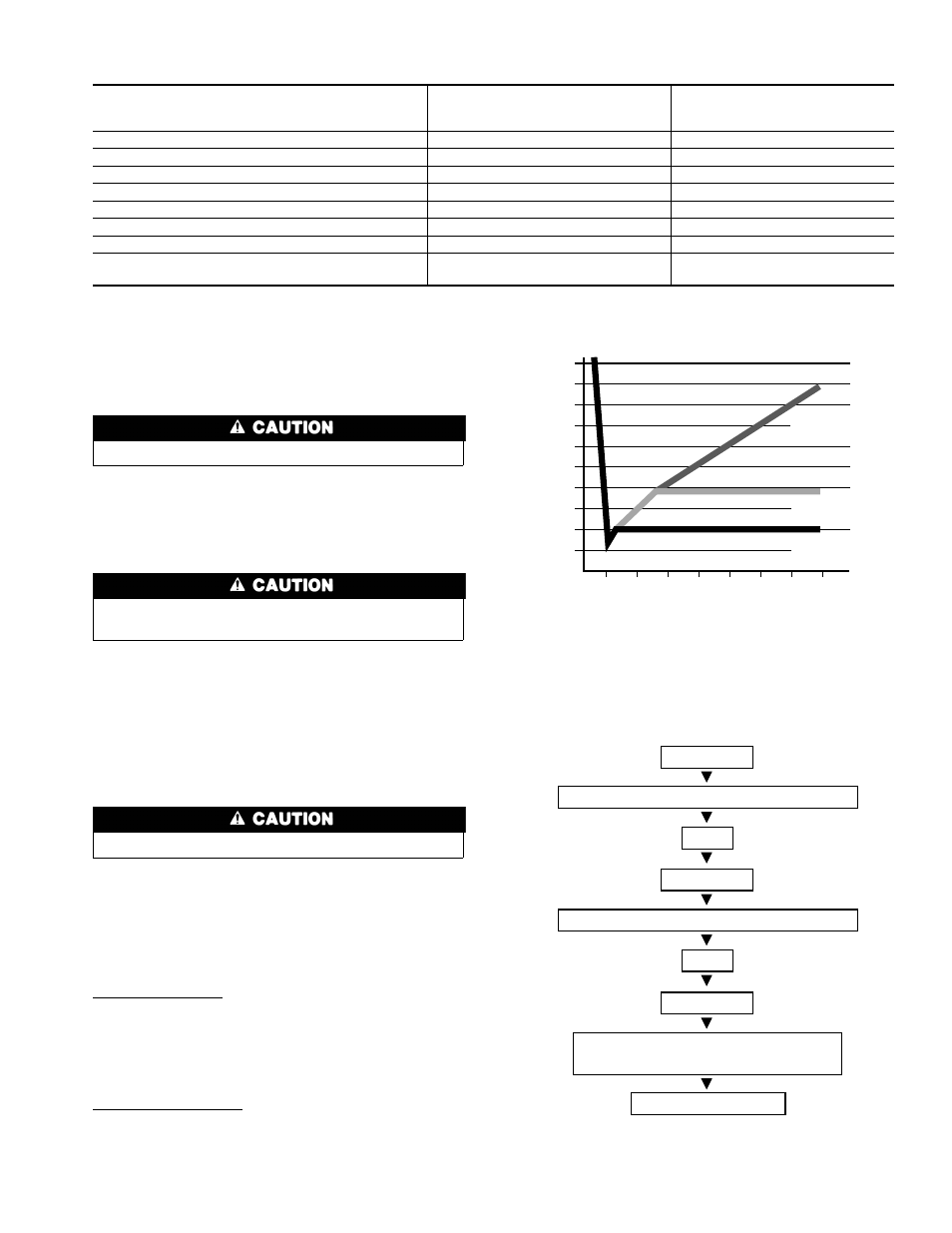

The deep vacuum method requires a vacuum pump capable of

pulling a vacuum of 500 microns and a vacuum gage capable of

accurately measuring this vacuum depth. The deep vacuum

method is the most positive way of assuring a system is free of air

and liquid water. (See Fig. 9.)

Triple Evacuation Method

The triple evacuation method should only be used when vacuum

pump is only capable of pumping down to 28 in. of mercury

vacuum and system does not contain any liquid water. Refer to

Fig. 10 and proceed as follows:

Fig. 9—Deep Vacuum Graph

A95424

500

MINUTES

0

1

2

3

4

5

6

7

1000

1500

LEAK IN

SYSTEM

VACUUM TIGHT

TOO WET

TIGHT

DRY SYSTEM

2000

MICRONS

2500

3000

3500

4000

4500

5000

A95424

Fig. 10—Triple Evacuation Method

A95425

CHECK FOR TIGHT, DRY SYSTEM

(IF IT HOLDS DEEP VACUUM)

EVACUATE

BREAK VACUUM WITH DRY NITROGEN

WAIT

EVACUATE

CHARGE SYSTEM

BREAK VACUUM WITH DRY NITROGEN

EVACUATE

WAIT

Table 2—Accessory Usage

ACCESSORY

REQUIRED FOR LOW-AMBIENT

APPLICATIONS

(BELOW 55°F)

REQUIRED FOR LONG-LINE

APPLICATIONS*

(OVER 50 FT)

Crankcase Heater

Yes

Yes

Evaporator Freeze Thermostat

Yes

No

Compressor Start Assist—Capacitor and Relay

Yes

Yes

Puron® Low-Ambient Pressure Switch

Yes

No

Wind Baffle

See Low-Ambient Instructions

No

Support Feet

Recommended

No

Hard Shutoff TXV

Yes†

Yes†

Liquid-Line Solenoid Valve for Heating

No

See Long-Line

Application Guideline

* For tubing line sets between 50 and 175 ft, or when vertical difference is greater than 20 ft, refer to Application Guideline and Service Manual — Residential Split-System

Air Conditioners and Heat Pumps Using Puron®.

† Required for all applications.

5