Sears 113.2945 User Manual

Page 6

Attention! The text in this document has been recognized automatically. To view the original document, you can use the "Original mode".

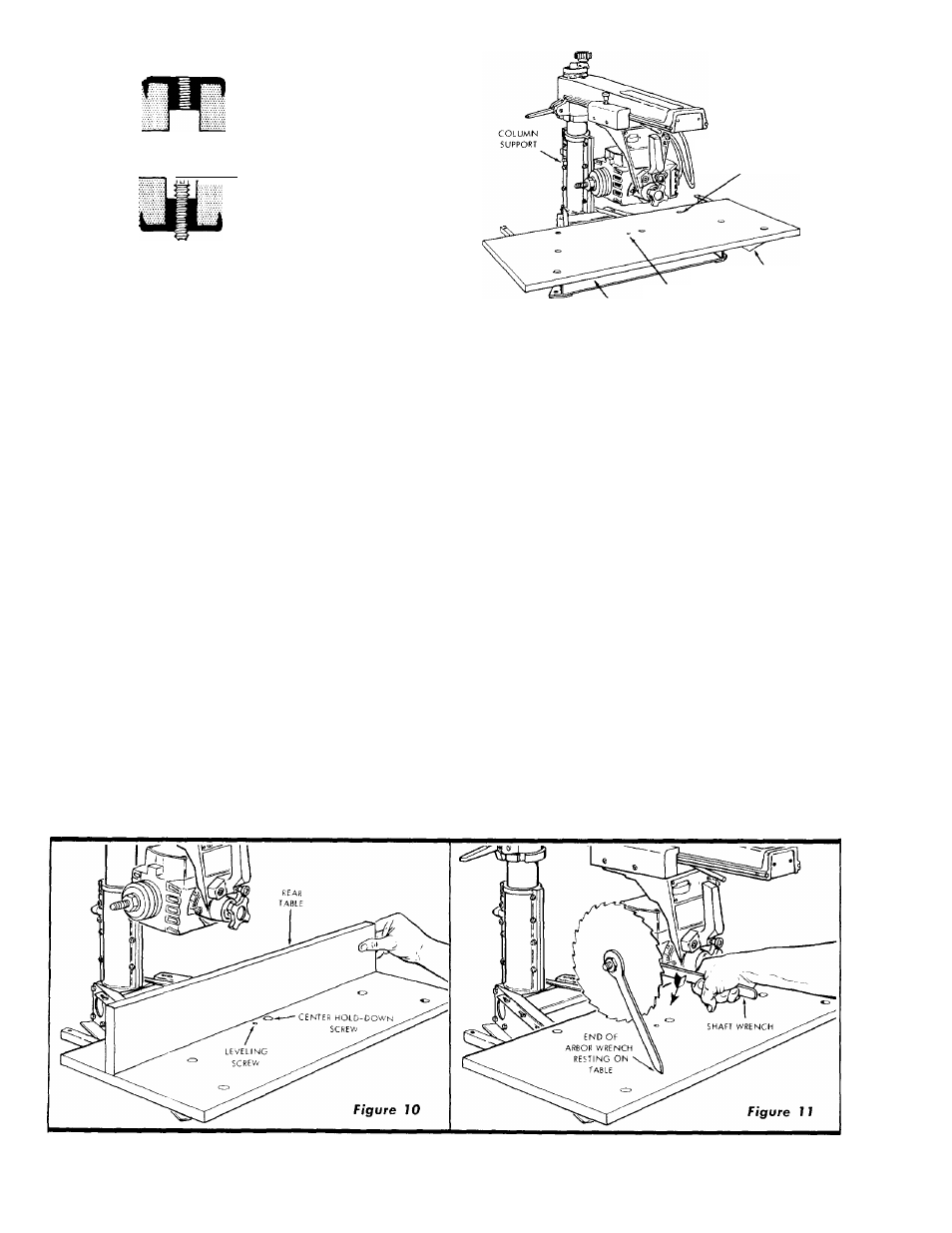

BOTTOM SIDE OF TABLE

T-NUT CORRECTLY INSTALLED

LEVELING SCBEW .

\ TOP OF TABLE

REAR TABLE

SUPPORT BRACKET

FRONT

TABLE

LEVELING SCREW INSTALLED

IN T-NUT

J;

SCREW

(No. 10 X S/B IN.)

HOLE FOR TABLE

HOLD-DOWN SCREW

(SEVEN,TOTAL)

Figure 8

R.H. TABLE SUPPORT

FRONT TABLE

LEVELING SCREW

HOLE

Figure 9

3. Loosen keylocking bolts (See figure 7) and insert a 3/16-

inch Hex-L wrench into the socket-head set-screw that

adjusts the column tube wedge key, as shown in figure 7.

Rotate the set-screw slowly in (clockwise) until no side

play can be felt in radial arm.

4. Check for binding by rotating the elevation crank. If the

crank rotates with noitceable resistance, loosen the set

screw by rotating the Hex-L wrench counterclockwise

until rotation is normal. An effective method for finaliz

ing the set-screw adjustment is to rotate the screw while

the elevation crank is being rotated, checking for side

play in radial arm as the adjustment progresses. The

adjustment is correct when all side play of radial arm

Is eliminated and only very slight additional resistance

can be felt when rotating the elevation crank.

5. If some radial arm side play can still be detected after

performing the above adjustment, it will be necessary

to adjust the forward five screws through the right-,

and left-hand column supports as follows;

a. While rotating the elevation crank, tighten the five

column adjusting screws slightly at the forward edge

of column supports. Each screw should be tightened

only slightly, and each one the same amount, until

a slight resistance can be felt when rotating the

elevation crank, then each screw backed off just

enough to restore a normal feel to the elevation

crank.

b. Recheck the adjustment of the column tube wedge

key set-screw as outlined in preceding instructions.

6. After the above adjustments have been completed, re

check the radial arm for absence of side play.

7. When all side play has been eliminated, lock the column

tube key in place by tightening keylocking bolts. (See

figure 7.)

STEP THREE-INSTALLATION OF FRONT TABLE

1. Place the large (front) table board upside-down on floor.

Distinguish between the one through-bored (leveling

screw) hole near the center of the board, and the seven

counterbore holes. The counterbores are in the top sur

face of the board. Drive the T-nut into the through-hole.

(See figure 8 which shows the T-nut installed.)

2. With the front table board still in the upside-down posi

tion, locate the two pre-drilled screw holes near each

end of the table. Attach the two rear table support

brackets to the table with two No. 10 x 5/8-inch screws

in each bracket. (See figure 8.)

3. Place the 1/4-20 U-clip nut on the base cross member

to receive the center front table attaching screw.

4. Place the large, front table board on the table supports.

(See figure 9.)

5. Align the counterbore holes with matching holes in table

supports.

6. Place a 17/64-inch plain washer and a l/4-20x 1-inch

pan-head machine screw from loose parts pack in each

of the six counterbore holes located above the table

supports. Use a l/4-20x 1-1/4-inch pan-head machine

screw in counterbored hole at the center of the table

board.