Controls, No lubrication required at these points, Periodically lubricate these points – Sears 113.2945 User Manual

Page 12: Proper operating procedures, Lubrication

Attention! The text in this document has been recognized automatically. To view the original document, you can use the "Original mode".

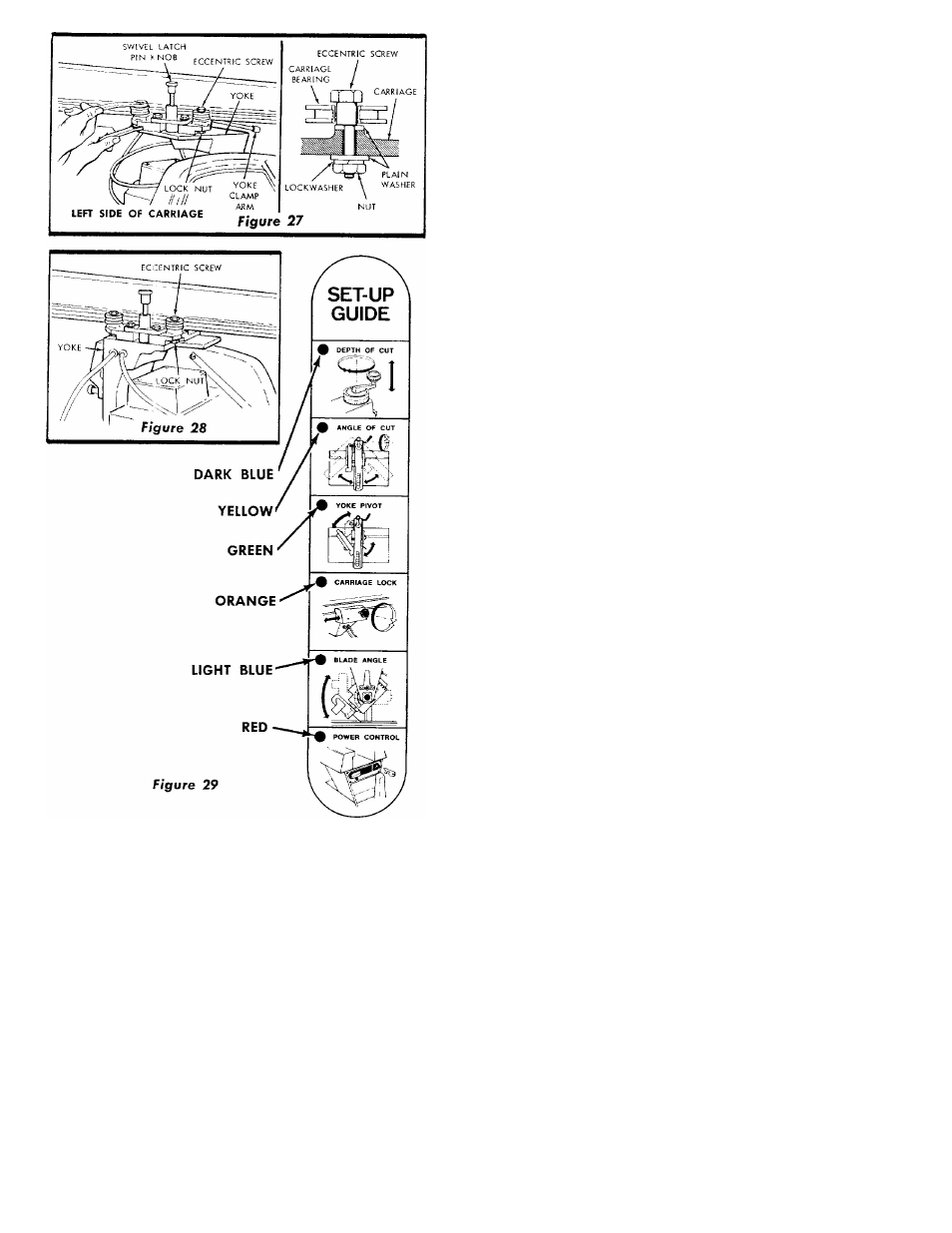

4. Rotate the yoke still farther (figure 28) to position the

cutout under the forward eccentric lock nut to provide

access for the wrench and adjust the forward carriage

bearing as described in preceding instructions.

5. Check the bearing adjustment by grasping the yoke and

attempting to ''rock ' the carriage. If no movement is

evident, move the carriage along the radial arm to make

sure no binding occurs at any point on the arm.

6. Rotate the yoke clockwise (viewed from above) until it

indexes at the crosscut position and tighten the yoke

clamp arm.

7. Install the left-hand carriage cover with two screws.

PROPER

OPERATING PROCEDURES

CONTROLS

A series of six diagrams are located on the top surface of

radial arm in order to designate the controls that must be

used in basic "set-ups" and operating procedures. (See

figures 23 and 29.) The inexperienced operator should

become familiar with these diagrams before operating

the saw.

1. "DEPTH OF CUT ". The d iagram shows the elevation

crank (5, figure 23) which is used to raise and lower

the blade. A dark blue circle is on the crank handle.

2. "ANGLE OF CUT". Two levers are involved In releasing,

securing and indexing the angle of radial arm. These

are; arm lock handle (7, figure 23) and arm latch handle

(8, figure 23), each marked with a yellow circle.

3. "YOKE PIVOT". Two controls are used in this operation.

They are: swivel index knob (2, figure 23) and yoke

clamp arm (1, figure 23), each marked with a dark olive

green circle.

4. "CARRIAGE LOCK". The carriage lock knob (4, figure

23), is rotated clockwise to secure the carriage on radial

arm, and counterclockwise to release it. An orange

circle is at the center of the knob.

5.

"BLADE ANGLE". The two controls used in angular

positioning and indexing of the motor to provide the

desired saw blade angle are: bevel lock knob (12, figure

23) and bevel index knob (11, figure 23). A light blue

circle is attached to each of these controls.

6.

"POWER CONTROL". The ON-OFF switch (15, figure

23) is located in the upper left-hand area of the carriage

and has a red circle directly under it.

LUBRICATION

This Craftsman saw is a fine machine and should be given

the best of care. If kept clean and properly lubricated, it

will give many years of trouble-free service. Before describ

ing the various points which may periodically require lubri

cation, IT IS MORE IMPORTANT TO FIRST MENTION THE

VARIOUS SPOTS WHICH SHOULD NOT BE LUBRICATED.

NO LUBRICATION REQUIRED

AT THESE POINTS

Do not lubricate the motor bearings. These are sealed

ball bearings and require no added lubrication.

Do not lubricate carriage bearings or tracks.

PERIODICALLY LUBRICATE THESE POINTS

Use SAE No. 10W-30 auto engine oil and refer to Parts List

for locations of parts listed below.

1. Apply a few drops of oil along the swivel index pin

only if the pin has a tendency to stick. Remove the left-

hand carriage cover and use oil sparingly to prevent

it from getting on the ball bearings or races.

2. A light film of oil can be wiped on the face of the column

tube and keyway to lubricate the fit between this part

and the key and column support.

3. An oil hole is provided in the top of elevation crank to

facilitate lubrication of the elevation shaft and radial

arm cap bearing surface.

4. The threads on elevation shaft are lubricated by remov

ing the elevation crank and radial arm cap.

1 2