Use of the dado head, Molding or shaping, Removal and installation of manual brake assembly – Sears 113.2945 User Manual

Page 15

Attention! The text in this document has been recognized automatically. To view the original document, you can use the "Original mode".

USE OF THE DADO HEAD

The dado saw (or head) is a special set of blades for cutting

grooves and dados. The Craftsman 8-inch Kromedge Dado

Set may be purchased at any Sears Retail Store or Catalog

Order House. The complete head consists of two outside

blades 1/8-inch thick, six chipper blades 1/8-inch thick

and paper washers for 1/16-inch width adjustments. With

these blades, grooves may be made in widths of 1/8-inch,

1/4-inch, and additional widths in steps increased by

1/16-inch each, up to a maximum of 13/16-inch. Outside

blades may be used alone, but chippers cannot be used

alone. When the maximum 13/16-inch width of dado is

used on the motor shaft, the outside loose collar must not

be used. The width of the dado can be reduced while using

the loose collar and two or more passes may be made with

the work to obtain the desired width of cut. Whenever two

or more chippers are used, the cutting ends should be

staggered as evenly as possible around the circumference.

Fractional adjustments in thickness of the head can be

made by using paper washers between the outside blades

and chippers.

Dado head operations are essentially the same as those

operations using a standard saw blade — but the dado

head takes a bigger bite, therefore, the work-piece should

be held more firmly. When a groove wider than the dado

head is needed, make two or more passes, with cuts spaced

to overlap a trifle. Dado work is performed in the cross-cut

position. Ploughing is done in the ripping position. If the

rip or plough position is used, the saw guard and anti

kickback pawl assembly should be adjusted as described

in the paragraph "RIPPING". Rabbeting is done with the

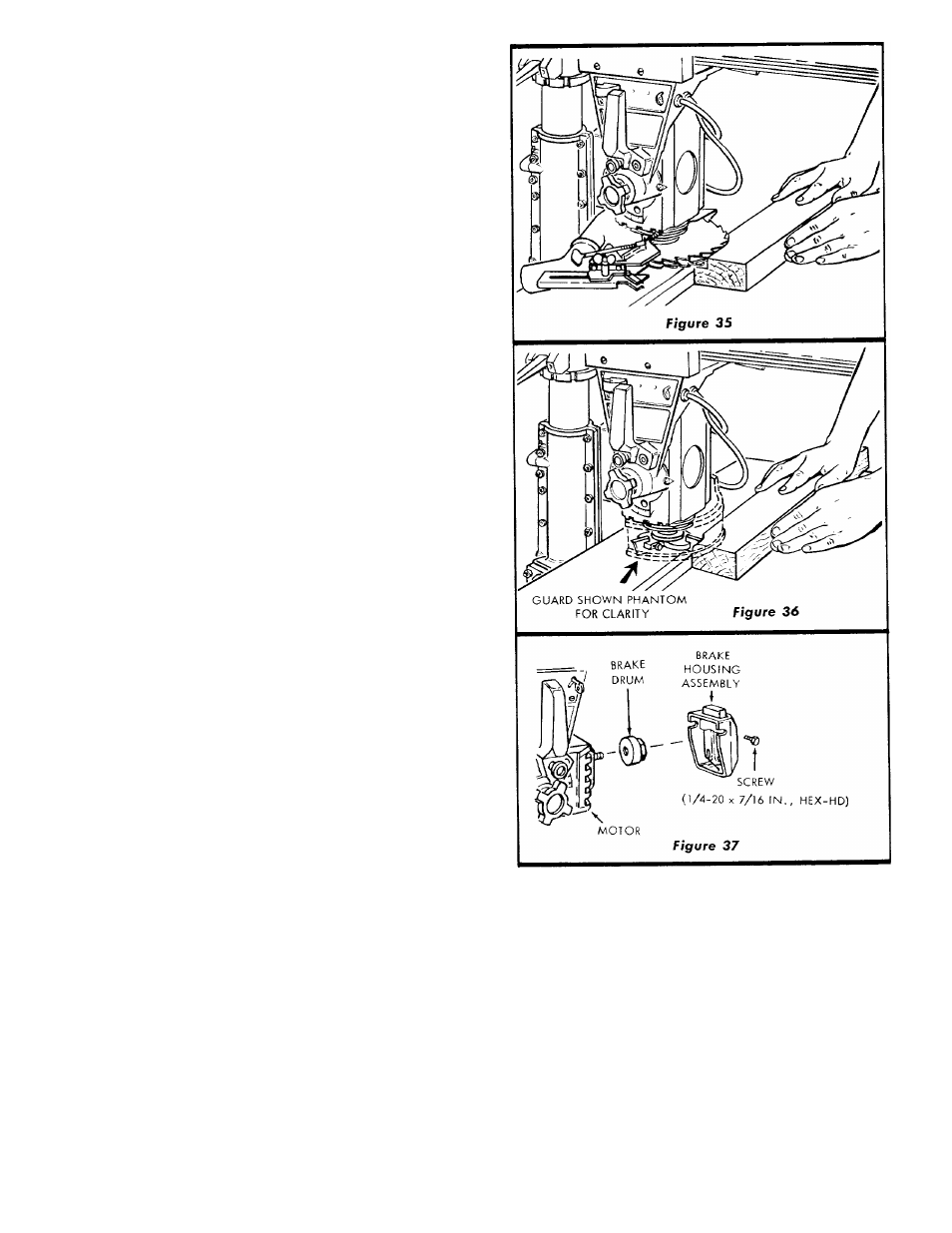

motor shaft in a vertical position. (See figure 35.) When

rabbeting, the motor is indexed 90° to the vertical position

so the blades are between the table top and motor, and

the yoke is indexed 90° clockwise and locked. The saw

is moved back on the radial arm and locked to the arm

when the amount of the blade extending forward of the

fence is equal to the depth of the rabbet desired. If the

depth of the rabbet is large, do not attempt to cut it in one

operation. Lower the radial arm until blades are in a

position to cut the desired width of rabbet in the edge of

the board. The discharge elbow should be directed to the

rear of the saw.

MOLDING OR SHAPING

This work is performed with Craftsman Molding Cutter

Heads, and a set of cutters depending on the type of mold

ing cut desired. The saw is positioned in the same manner

as that described for rabbeting. (See figure 36.) Since the

position of the cutters can be adjusted with respect to the

fence and table top, any or all of the cutter shapes may

be used.

The Molding Cutter Guard should be used with Molding

Cutter Head.

REMOVAL AND INSTALLATION OF

MANUAL BRAKE ASSEMBLY

Prior to performing any operation that requires the use of

the motor shaft opposite the saw blade encl (routing, dove

tailing, boring, sanding, etc.), it will be necessary to remove

the manual brake assembly to expose the end of the shaft.

This is accomplished as follows:

(See

figure 37.)

1. Remove the guard assembly, saw blade and both collars.

2. Remove two 1 /4-20 x 7/16-inch, hex-head screws to free

the brake housing from the motor.

3. Pull the brake housing off end of motor housing, leaving

the brake shoe and spring in the brake housing.

4. Hold the motor shaft (at saw end) with the shaft wrench

and remove the brake drum from motor shaft with the

arbor wrench. (This end of motor shaft has right-hand

threads.)

5. Install a chuck or other accessory as required, on end

of motor shaft and tighten it firmly on the threads. The

motor shaft should be held with the shaft wrench at saw

end of shaft while tightening the chuck or other accessory.

6. When finished with the particular operation being per

formed, install the manual brake assembly by reversing

the preceding removal procedure. (See figure 37.)

7. Install saw blade and guard assembly.

1 5