Assembly, Tools required for assembly, To remove pressure washer from carton – Sears 580.7515 User Manual

Page 7

Attention! The text in this document has been recognized automatically. To view the original document, you can use the "Original mode".

ASSEMBLY

Road ttiese Instructions aiKi Curator’s Wanual in its en

tirety before you attempt to assemble or operate your now

high pressure washer. Your high pressure washer has, for

the most part, been asserrtrled at the factory, except those

parts left unassembled. Before you can operate your new

high pressure washer, you must assentile the wheel Wt and

property connect the high pressure hose.

IF YOU HAVE ANY PROBLEMS WITH THE ASSEMBLY

OF YOUR PRESSURE WASHER, PLEASE CALL THE

PRESSURE WASHER HELPLINE AT 1-BOO-222-3136.

TOOLS REQUIRED FOR ASSEMBLY

o Mallet

a 2 adjustable wrenches OR the following wrenches:

•

5/16“ (8mm) con*ination wrench

6

1/2" (13mm) combination wrench

o 5/8" (16mm) combination wrench

• 11/16" (18mm) combination wrench

•

7/8" (22mm) combination wrench

•

15/16" (24mm) combination wrench

TO

REMOVE

PRESSURE

WASHER

FROM

CARTON

o Remove two boxes marked “PARTS INS! DP and re

move the parts contained in both boxes.

o Remove unit with one hand under pump and one hand

under recoil starter.

Refer to Page 6, “Contents of Hardware Pack” for an

illustrated listing of all the items included with your pressure

washer. Become familiar with each piece before assem

bling the pressure washer. Check all contents against the

illustrations on Page 6. If any parts are missing or dam

aged, call the Pressure Washer Helpline at 1-800-222

3136.

HOWTO SET UP YOUR PRESSURE WASHER

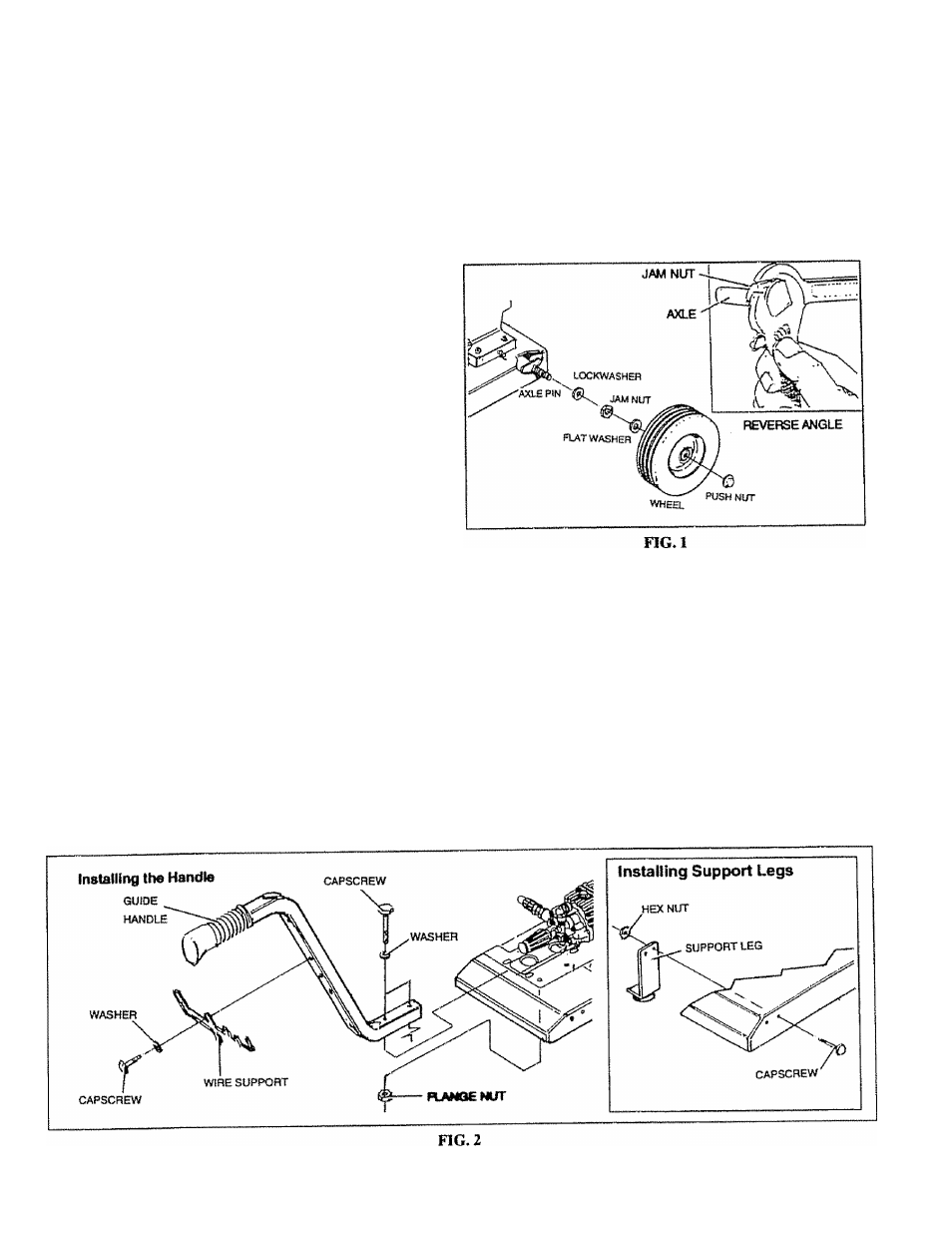

TO INSTALL THE WHEEL KIT

Installing the wheel kit requires the tools listed, the guide

handle and items included in the parts carton.

o Prop up the engine end of the main unit. This will allow

you to slip each axle pin into the holes provided on the

side of the base (Fig, 1).

With the axle pin inserted inside the base, grip the end

of the axle pin as shown with an adjustable or 15/16"

combination wrench. This will keep axle from spinning

as you fasten axle to the base with a 5/8" lock washer,

a 5/8"-18 JAM nut, and an Ml2 flat washer

Place wheels on the axles so the rib side of hub is

against mounting base.

Retain each wheel to its axle pin by tapping a push nut

onto end of axle with a mallet.

Attach support legs to base as shown in Fig, 2 with M8

X

20mm hex head capscrews and flange lock nuts.

Tighten with 13mm or 1/2-inch wrench on each fas

tener. Be sure legs are straight when you are finished.

Attach the guide handle to the base as shown in Fig 2

with two M8

X

40mm hex head capscrews, two M8

washers and two flange nuts