Clean cooling system, Replace spark plug, Service and adjustments – Sears 580.7515 User Manual

Page 16: Engine adjustments, Initial adjustment, Final adjustment, Engine speed, Nozzle maintenance, Responsibilities, Customer

Attention! The text in this document has been recognized automatically. To view the original document, you can use the "Original mode".

CUSTOMER

RESPONSIBILITIES

AIR

CLEANER

ELEMENT

FIG. 24

o Service cartridge by tapping gently on a flat surface.

Replace if dirty. Do not oil cartridge.

o Insert cartridge (new or used) and reassemble cover to

base as it was removed before. Tighten cover screws

securely.

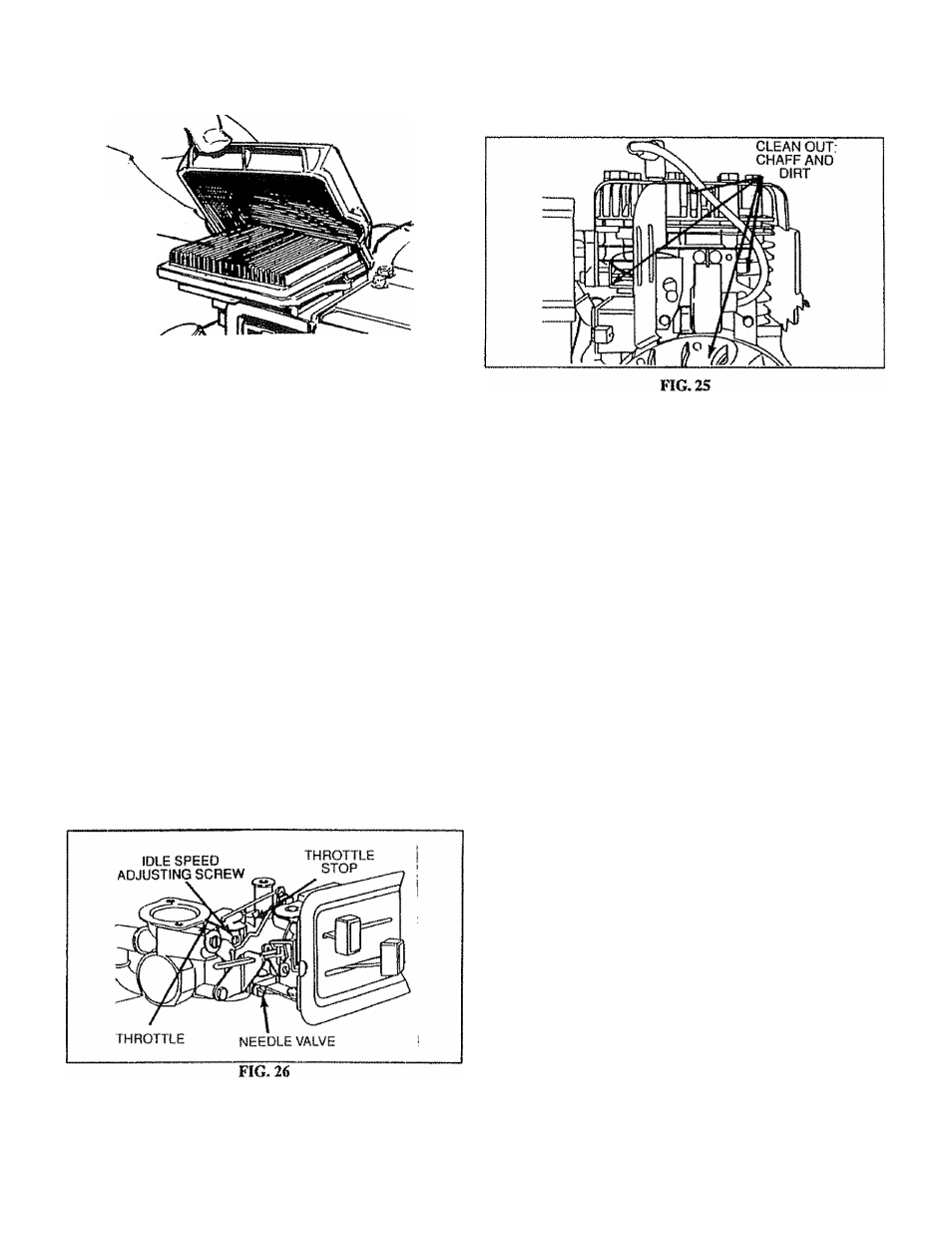

CLEAN COOLING SYSTEM

o Clean dirt or chaff from finger guard or rotating screen

every 8 hours to prevent engine damage caused by

overheating (Fig. 25).

Keep dirt and combustible debris off of muffler area.

REPLACE SPARK PLUG

Change the spark plug every 100 hours of operation or

once each year, whichever comes first. This will help

engine to start easier and run better. See pressure washer

specifications for the type of spark plug you need. Spark

plug gap is 0.030 inch (0.76mm).

SERVICE AND ADJUSTMENTS

ENGINE ADJUSTMENTS

Carburetor:

Differences in fuel, temperature, attitude or load may re

quire minor carburetor adjustment Air cleaner and air

cleaner cover must be assembled to carburetor before

starting engine.

INITIAL ADJUSTMENT

o Gently turn NEEDLE VALVE (Fig. 26) clockwise until it

just closes. Valve may be damaged by turning it inward

too far.

Next open NEEDLE VALVE 1-1/2 turns counterclock-

wfse.

FINAL ADJUSTMENT

» Start engine and let it warm up for at least five minutes.

o With engine running, turn NEEDLE VALVE inward

(clockwise - lean mixture) until engine just starts to

slow.

ENGINE SPEED

WARNING: NEVER TAMPER WITH ENGINE GOV

ERNOR WHICH IS FACTORY SET FOR PROPER

ENGINE

SPEED.

OVERSPEEDING

ENGINE

ABOVE FACTORY HIGH SPEED SETTING CAN BE

DANGEROUS.

This initial adjustment will permit the engine to be

started and warmed up.

NOZZLE MAINTENANCE

If the nozzle becomes restricted or clogged with foreign

materials, such as dirt, excessive pump pressure may

develop, A partially clogged nozzle can cause a pulsing

sensation during use. This generally is not a pump related

problem, but rather a clogged or partially restricted nozzle.

If the nozzle becomes clogged or partially restricted, imme

diately clean the nozzle with the kit included with your

pressure washer by following these instructions:

» Shut off the engine and turn off the water supply.

• Separate the wand from the gun.

» Remove nozzle from the end of the wand using a 2mm

or 5/64 alien wrench (like the one included in the kit).

» Use the wire included in the kit (Fig. 26 on Page 17) or

a small paper clip to free the foreign materials clogging

or restricting tfie nozzle .

¡6