Heating, Steam pressure (psig), Indoor – Carrier 38BA User Manual

Page 10: Unit, 40ba, Heater, Size, Number 1, Heaters

Attention! The text in this document has been recognized automatically. To view the original document, you can use the "Original mode".

HEATING

Accessory steam or hot water coils are designed

for installation inside the unit casing. Prevent

freeze-up when introducing outside air.

AGA approved gas-fired heaters and UL ap

proved electrical resistance heaters are recom

mended for use in external system ductwork;

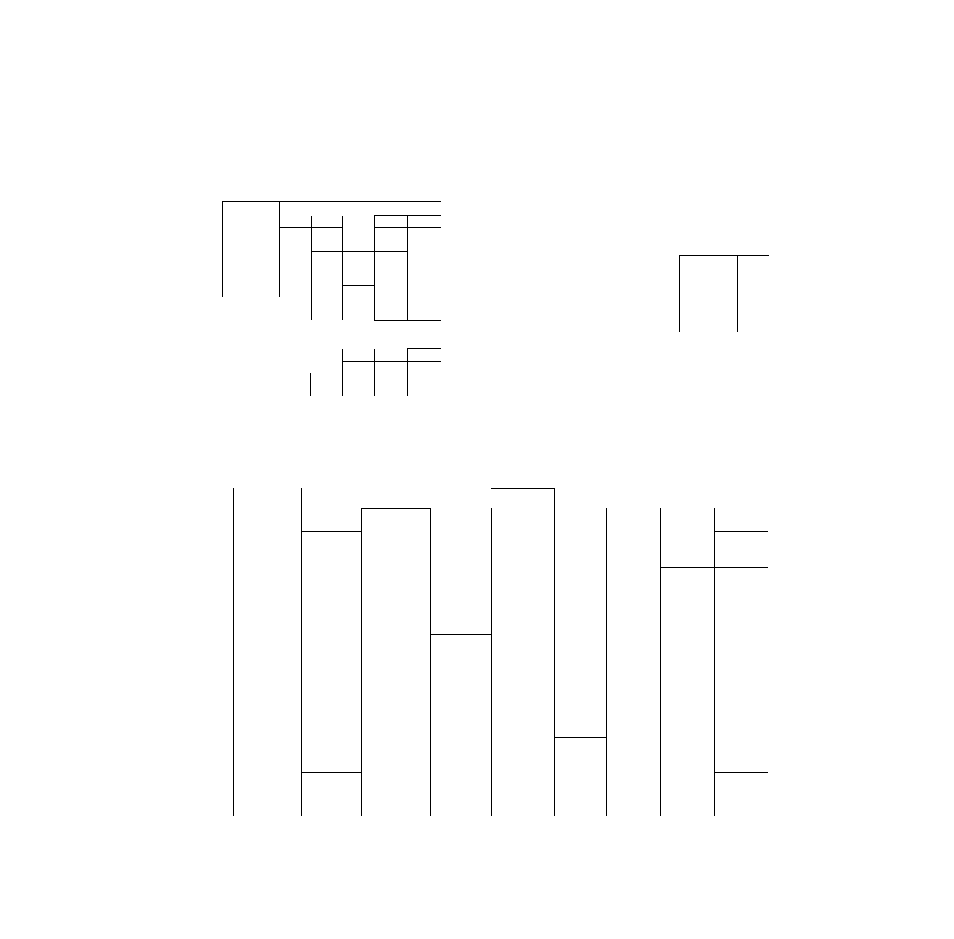

Table 1 — Heating Correction Factors

HOT WATER COIL

Water Temp

Ent Water

Entering Air Temp (F)

Drop (F)

Temp (F)

40

50

60

70

80

10

Ì80 1

1 15

1.06

96

87

77

200

1,35

1.25

1.16

1.07

.97

180

98

88

79

,70

60

20

200

1.18

1 09

1 00

90

81

220

1.37

1.28

1.20

1.1 1

1 01

180

79

70

61

52

42

30

200

1 00

91

85

73

.64

220

1 22

1 12

1 03

94

.85

STEAI^CO|L______ _ __

Entering Air Temp (F)

Steam Pressure (psig)

o”

2

5

NOTE: Multiply capacity given in Table 3 by the correction factor

for conditions at which unit is actually operating Correct leaving

air temperature using formula in Note 3 under Table 3

40

. 50

60

70

80

11 I 1 03

96

89

82

.14

1 07

1 00

93

86

19

1 1 1

1.05

98

91

install on leaving side to protect fan motor from

overheating; maximum allowable air temperature

over the fan is 140 F.

Ensure compliance with local and/or UL codes,

including those covering distance from combustible

materials and fan discharge, minimum stratification

to avoid condensation on the heater casing, and

positive interlock requirements, as well as other

standard practices outlined in the Carrier System

Design Manual.

Table 2 — Auxiliary Electric

Resistance Heater Data

INDOOR

UNIT

40BA

009

HEATER

SIZE

(kw)

9t

NUMBER

1

OF

HEATERS

2

3t

TOTAL

KW

■ 9

18

27t

HEATER

MIN

CAPACITY

AIR*

(1000 Btuh) (cfm)

30 6

2500

61.2

2500

91 8

2500

‘Minimum cfm required to ensure safe operation of heater

fMaximum allowable size, number and total kw that may be

mounted on unit discharge

NOTES

1

40BA009 accessory electric resistance heaters are UL approved

for mounting directly to the fan discharge

2

For 10 percent decrease in voltage, decrease input kw and

capacity by 19 percent For 10 increase in voltage, increase

input kw and capacity by 21 percent

Table 3 — Heating Ratings

NONFREEZE SI EAM COILS

2-ROW HOT WATER COILt

UNIT

CFM

Сарае ity

1 Row

1000 Btuh)

2 Row

L

1 Row

db

2 Row

Co p.

Ldb

Gpm

PD

2,200

06

_

101

_

170

132

17

3

5

40RR008

3,000

118

_

96

-

211

125

21

4

6

3,800

133

-

93

240

119

24

5

5

3,000

126

—

99

—

222

129

22

2

5

40RR012

4,000

150

—

95

—

268

122

27

3,0

5,000

171

92

307

117

31

3

7

4,500

186

348

98

^361

134

36

Г

9

40RR016

6,000

217

428

94

126

428

126

43

2.5

7,500

248

494

91

121

490

121

49

3.4

6,000

209

406

92

123

ШГ

126

41

-2 4~"

40RR024

8,000

246

492

88

117

500

118

50

3

5

10,000

272

563

8A

112

580

114

58

3

9

7,500

312

_

99

_

573

ТТГ

58

"■""

3.7

"

40RR028

10,000

361

—

96

-

690

124

69

4.8

12,500

406

_

93

—

786

118

79

6

2

9,000

344

—

95

—

645

Í

22

65

4

4

40RR034

12,000

398

—

91

—

768

119

77

6

0

15,000

443

-

87

-

874

114

87

7

4

12,000

665

_

111

1035

140

104

8

7

40RR044

16,000

780

—

105

—

1265

133

127

12.6

20,000

875

-

100

1470

128

147

17

1

15

,

boo

785

—

109

_

Í

300

T

40

”“

Тзо

"“'“”

9

7

40RR054

20,000

915

-

102

1585

133

159

14

1

25,000

1030

-

98

_____ _

1830

127

183

17,6

. — Capacity (1000 Btuh)

NOTES

1 Maximum

operating limits for heating coils 200 psig and

Ldb — Leaving Air Dry-Bulb Temp (F)

PD — Pressure Drop (ft water)

‘Based on 2 psig steam, 60 F entering air temperature

tBased on 200 F entering water, 20 F water temperature drop,

60 F entering air temperature

400 F

2 Maximum leaving air temperature 140 F

capacity

3 Leaving db = edb

+

Gpm

1 08

X

cfm

capacity

500

X water temp drop

10