Carrier 38ED User Manual

Page 7

Attention! The text in this document has been recognized automatically. To view the original document, you can use the "Original mode".

Table 5 — Refrigerant Charging Methods

MODEL

METHODS OF CHECKING OR

ADJUSTING CHARGE

METHODS FOR COMPLETE

RECHARGING

38ED

System Refrigerant Control

System Refrigerant Control

Non TXV

TXV

Non TXV

TXV

ALL

Chargemaster®

or

Charging Chart

Sight

Glass*

Weight Method

plus

Chargemaster or

Charging Chart

Weight Method

plus

Sight Glass*

'Sight glass field supplied and installed in liquid refrigerant line

Table 6 — Service Data

MODEL

38ED

R-22 CHARGE*

(lb)

CONDENSER

FAN RPM

018

6 5

024

74

830

030

7 6

036

8 5

042

90

048

8.0

840

060

10 2

'Factory refrigerant charge is adequate when evaporator and con

densing unit are the same size and are connected with 25 ft or

less of field-supplied tubing of recommended size or Carrier

accessory tubing

(AccuRater™ System)

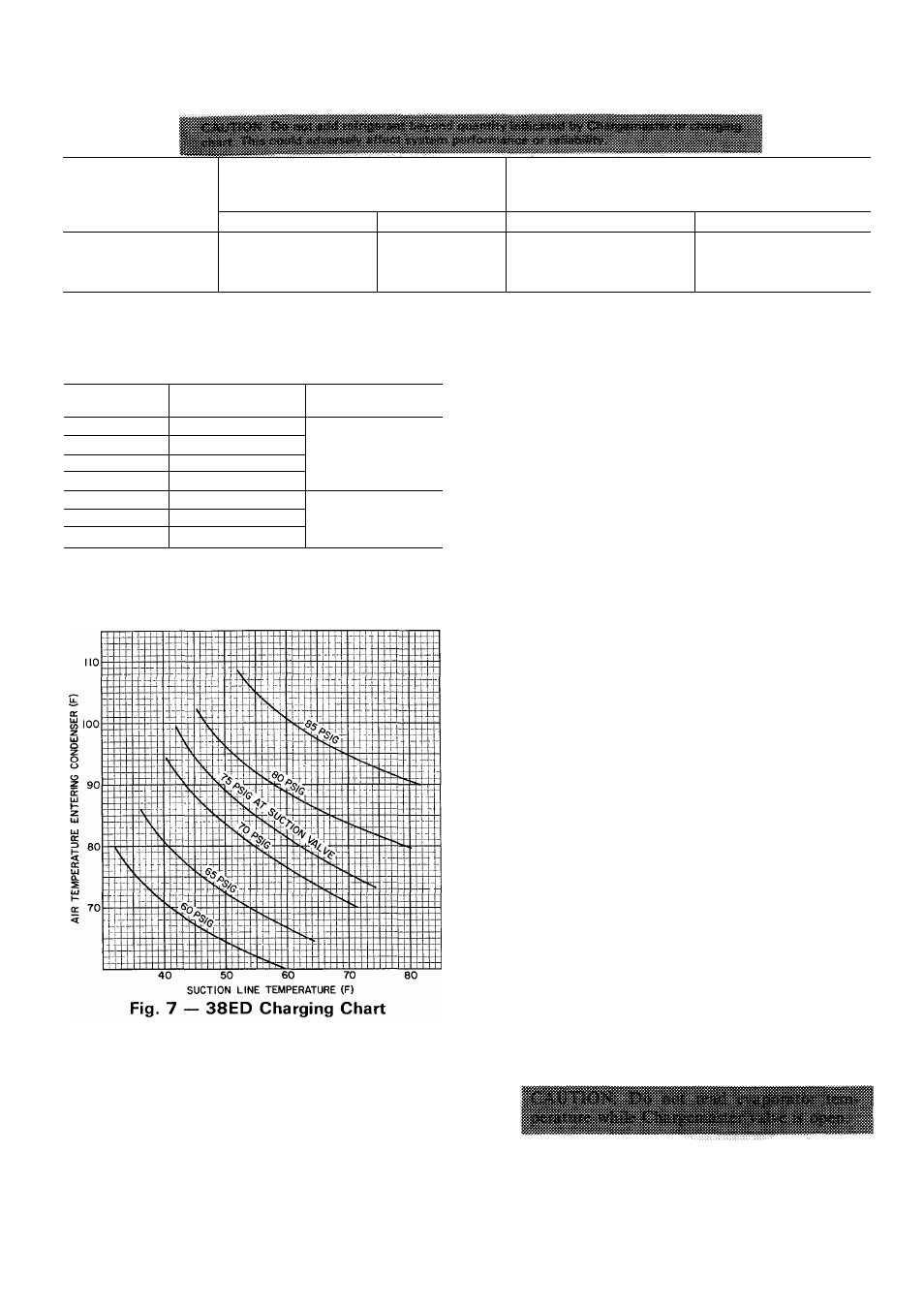

2. Measure suction pressure by attaching a gage to

suction valve service port.

3. Measure suction line temperature by attaching a

service thermometer to unit suction line near suc

tion valve. (Insulate thermometer for accurate

readings.)

4. Measure outdoor (condenser inlet) air dry-bulb

temperature with a second thermometer.

5. Refer to Charging Chart (Fig. 7). Find air tem

perature entering condenser and project hori

zontally to curve showing suction pressures

(psig at suction valve).

6. From this intersection, project vertically down

ward to suction line temperature.

7. If unit has a higher suction line temperature than

charted

temperature,

add

refrigerant

until

charted temperature is reached.

8. If unit has a lower suction line temperature than

charted temperature, bleed refrigerant until

charted temperature is reached.

9. If air temperature entering condenser or pressure

at suction valve changes, charge to new suction

line temperature indicated on chart.

CHARGEMASTER® METHOD — Operate unit

for 10 minutes before using Chargemaster (Carrier

Part No. 38GC680004).

1. Tape Chargemaster feeler bulb to suction line

close to condensing unit. Insulate bulb. Ensure

suction line is clean for good contact with bulb.

(Uninsulated bulb or dirty suction line will seri

ously affect accuracy of temperature readings.)

2. Connect refrigerant drum to Chargemaster inlet

port keeping drum in position for vapor charging.

3. Connect Chargemaster outlet port to unit suction

valve service port.

4. Crack valves on refrigerant drum and Charge-

master to purge lines from drum to suction valve.

After purging lines, close valve on Chargemaster

only.

5. Measure outdoor air dry-bulb temperature.

6. Crack unit suction valve and read evaporator

temperature at red needle position on Charge-

master temperature gage and suction line tem

perature at black needle position.

7. Enter Chargemaster Charging Chart, Table 7, at

outdoor air temperature (step 5) and evaporator

temperature (step 6). Find the suction line tem

perature required for correct system charge. If