Step 4 — make electrical connections — be, Table 3 — accessories, Step 4 — make electrical connections – Carrier 38ED User Manual

Page 4

Attention! The text in this document has been recognized automatically. To view the original document, you can use the "Original mode".

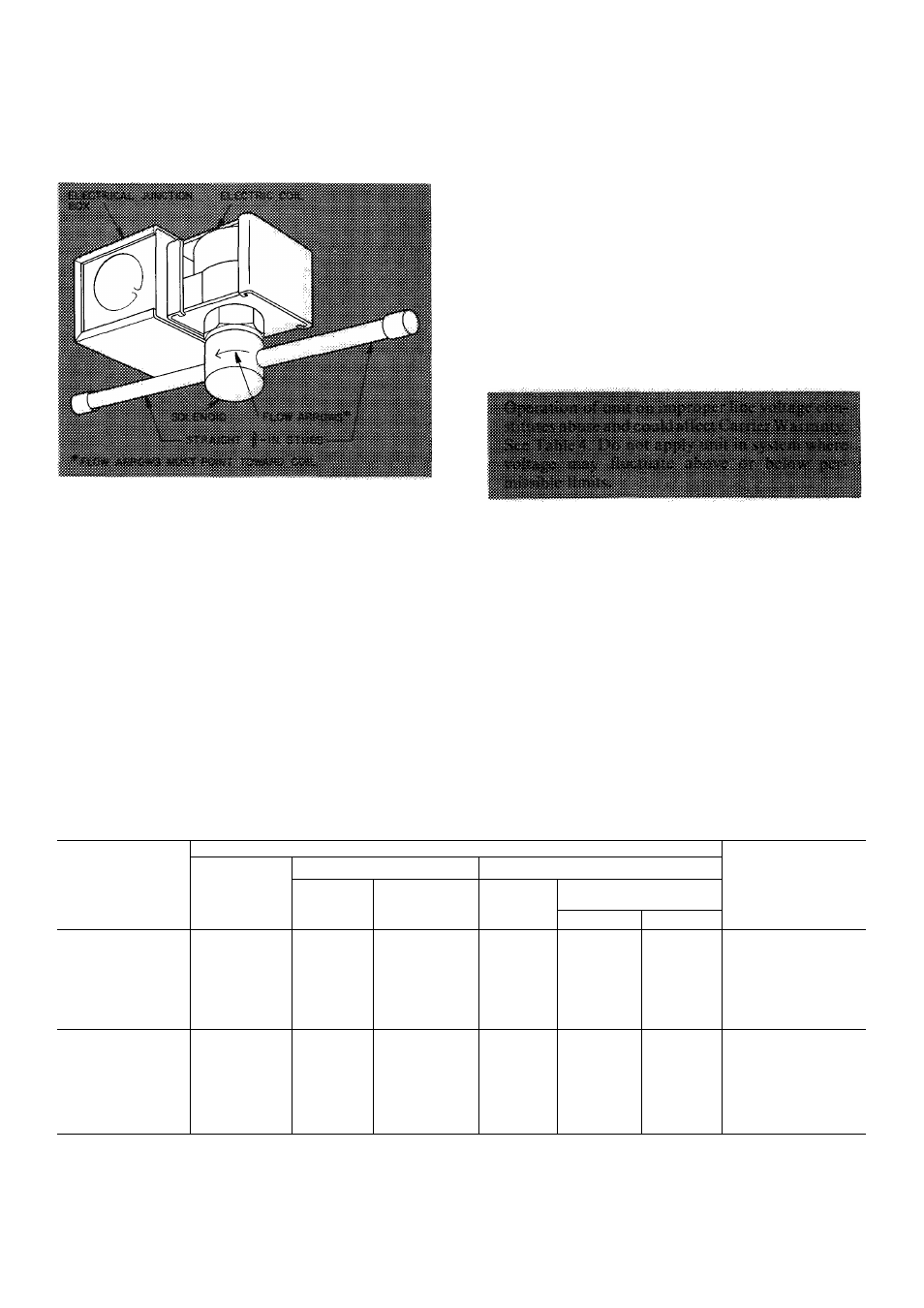

See Fig. 4 and install as follows:

1. Remove coil liquid line cap and discard.

2. Attach field-supplied flare fittings to solenoid

valve straight 3/8-in. stubs.

3.

4.

5.

Connect solenoid to tube assembly, making sure

solenoid flow arrows point towards indoor coil.

Mount solenoid in any position except valve

body at top and electric coil at bottom (see Fig. 4).

Tighten flare nuts.

Wire coil into system control circuit as shown in

Fig. 5.

Step 4 — Make Electrical Connections

— Be

sure field wiring complies with local and national

fire, safety and electrical codes, and that voltage to

unit is within limits shown in Table 4. Contact local

power company for correction of improper line

voltage.

Fig. 4 — Solenoid Installation

Table 3 — Accessories

PART NO.

DESCRIPTION

MODEL 38ED

HH01AD040

HH93AZ040

HH51AR001

Low-Voltage Control — Honeywell Deluxe Thermostat

Thermostat Subbase

Comfort Control Center (Use with HH01AD040)

HH07AT170

HH07AT174

HH93AZ176

Low-Voltage Control — Honeywell Thermostat

Thermostat Subbase (with Automatic Changeover)

HH01AD042

Low-Voltage Control — Honeywell Thermostat

All

HH93AZ042

Thermostat Subbase

38VH90000106

Thermocharger™ Replacement Unit Module (Six 38VH900001)

38GS900102

Indoor Fan Relay (Six HN61KJ210)

HT01AW230

Low-Voltage Transformer (60va) — Available thru Carrier Service Parts

09WQ036.060

Refrigerant-to-water heat exchanger for chilled water systems

38GS900321

Liquid Line Filter Drier (Six 38GS900332)

28VQ9000112

Twelve %

X

IVs-in suction connection adapters

042,048,060

TUBING

PACKAGES

TUBING*

MODEL

38ED

Length

(ft)

Liquid

Suctiont

OD

(in.)

Tube End

OD (in.)

OD

(in.)

Tube End

OD (in.)

Evap

Cond

38LS934151

15

ys

3/8

3/4

3/4

3/4

38LS934201

20

3/8

3/8

3/4

3/4

3/4

38LS934251

25

3/s

3/8

3/4

3/4

3/4

38LS934301

30

3/s

3/8

3/4

3/4

3/4

38LS934351

35

3/8

3/8

3/4

3/4

3/4

38LS934401

40

3/8

ya

3/4

3/4

3/4

38LS934501

50

3/s

ya

3/4

3/4

3/4

38LS978151

15

3/8

3/8

3/8

3/4

3/4

38LS978201

20

3/8

ya

3/8

3/4

3/4

38LS978251

25

3/s

3/8

3/8

3/4

3/4

036,042,

38LS978301

30

3/s

3/8

3/8

3/4

3/4

048,060

38LS978351

35

3/8

3/8

3/8

3/4

3/4

(See Note 2)

38LS978401

40

3/8

3/8

3/8

3/4

3^

38LS978501

50

3/8

3/s

3/8

3/4

3/4

1.,

*For maximum capacities, use suction line sizes recommended in

Table 1 Use of accessory tubing packages smaller than recom

mended may result in slight capacity loss (see Note 2)

fSuction line is insulated and has a 90 degree bend at one end

NOTES;

1

Do not cut ys-in OD liquid line to a length shorter than 10 feet

Do not cut ya-in OD suction lines

Field-supplied IVs-in suction line is recommended on 38ED

036,042,048 and 060 If accessory tubing package is used, a

capacity reduction can result