Carrier 19DA User Manual

Page 2

Attention! The text in this document has been recognized automatically. To view the original document, you can use the "Original mode".

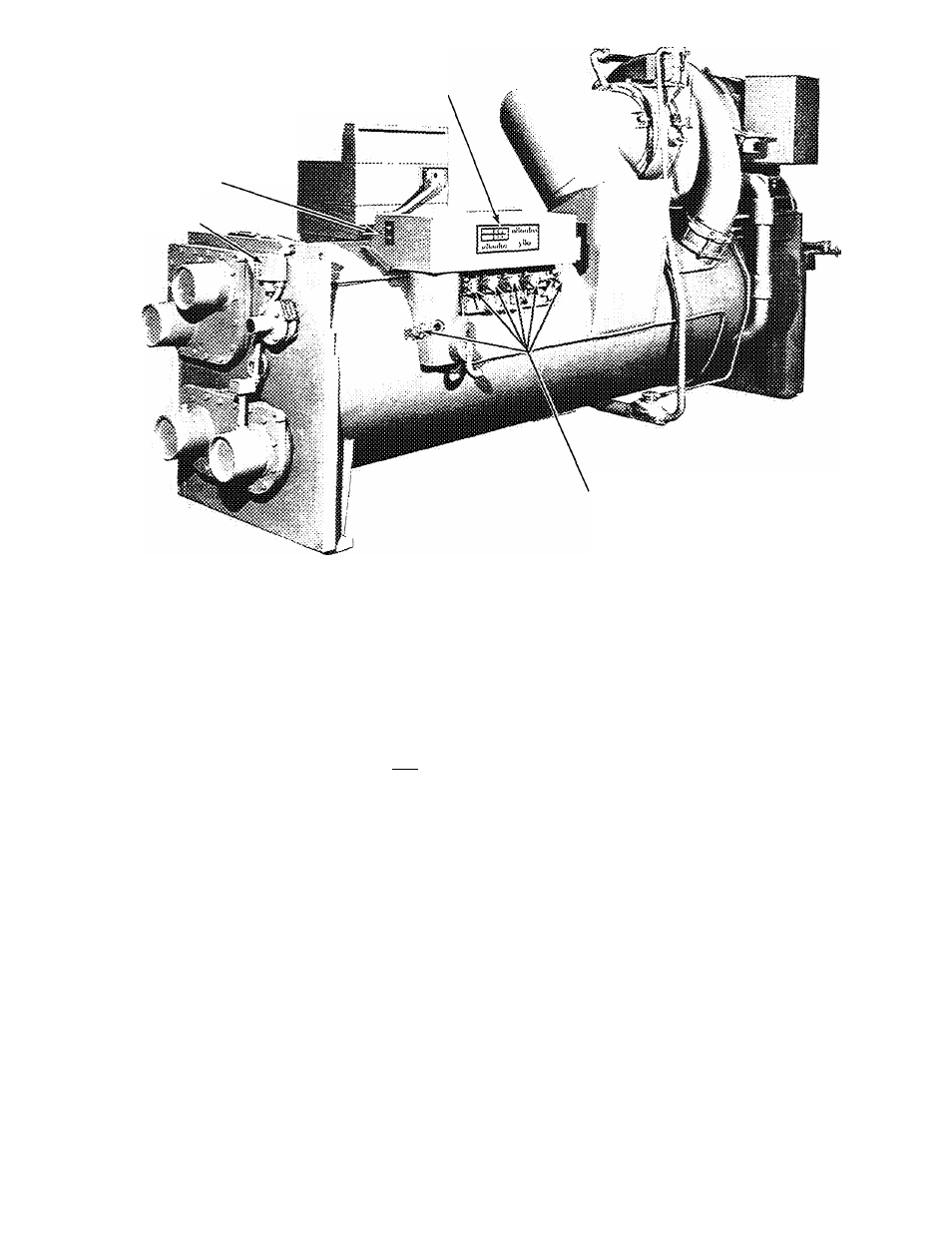

PURGE VALVE OPERATION PLATE

PURGE PUMP

SWITCH

CHILLED WATER

LOW TEMP CUTOUT

PURGE OPERATING VALVES (6)

Fig. 2 - 19DA Rear View

1

.

2

.

Record and date vacuum reading shown on

compound pressure gage located on compres

sor (Fig. 1).

With this reading and the reading taken when

the machine was received, determine vacuum

leak rate using the following formula:

Leak Rate = Vacuum loss

H- No. of days between readings

3. If vacuum leak rate is 0.05 in. Hg or less per

24 hours, the machine is sufficiently tight.

If vacuum leak rate exceeds this rate, per

form "Refrigerant Pressure Test” and cor

rect leakage.

EXCESSIVE OR TOTAL VACUUM LOSS - Ex

cessive or total vacuum loss can be caused by

accidental opening of a valve or other connec

tion. If this is suspected, proceed as follows:

1. Install a mercury manometer (absolute pres

sure type) to the cooler charging valve (Fig. 1).

A dial type gage can not indicate the small

amount of leakage acceptable during a short

period of time.

2. Pull a vacuum on the machine equal to 25 in.

Hg. Use external vacuum pump or energize

purge pump (Fig. 2) using operation No. 2

described on the purge valve operation plate

shown on Fig. 2.

3. Let the machine stand with this vacuum, and

then perform the leak rate check previously

outlined.

4. If the vacuum leak rate is 0.05 in. Hg or less

per 24 hours, the machine is sufficiently tight.

Perform all steps under "Machine Dehydra

tion" (pg 3).

5. If the vacuum leak rate exceeds 0.05 in. Hg

per 24 hours, perform all steps under "Re

frigerant Pressure Test" (pg 2) and correct

leakage. Perform all steps under "Machine

Dehydration."

6. Remove the mercury manometer from cooler

charging valve.

REFRIGERANT PRESSURE TEST

1. Pull approximately five inches of vacuum on

the machine by energizing machine purge pump

(Fig. 2). Use operation No. 2 described on the

purge valve operation plate or with an external

vacuum pump connected to the cooler charging

valve (Fig. 1).

2. Charge approximately one gallon of Refrig

erant 11 thru the cooler charging valve. Refer

to refrigerant charging instructions (pg 4).

3. Increase pressure to eight to ten psi with dry

air or nitrogen thru the cooler charging valve.

DO NOT EXCEED TEN PSI.

4. Test all joints, valves, fittings, flanges, etc.

with a halide or electronic leak detector.

CAUTION: Due to rupture disc limitations :

DO NOT EXCEED TEN PSI.