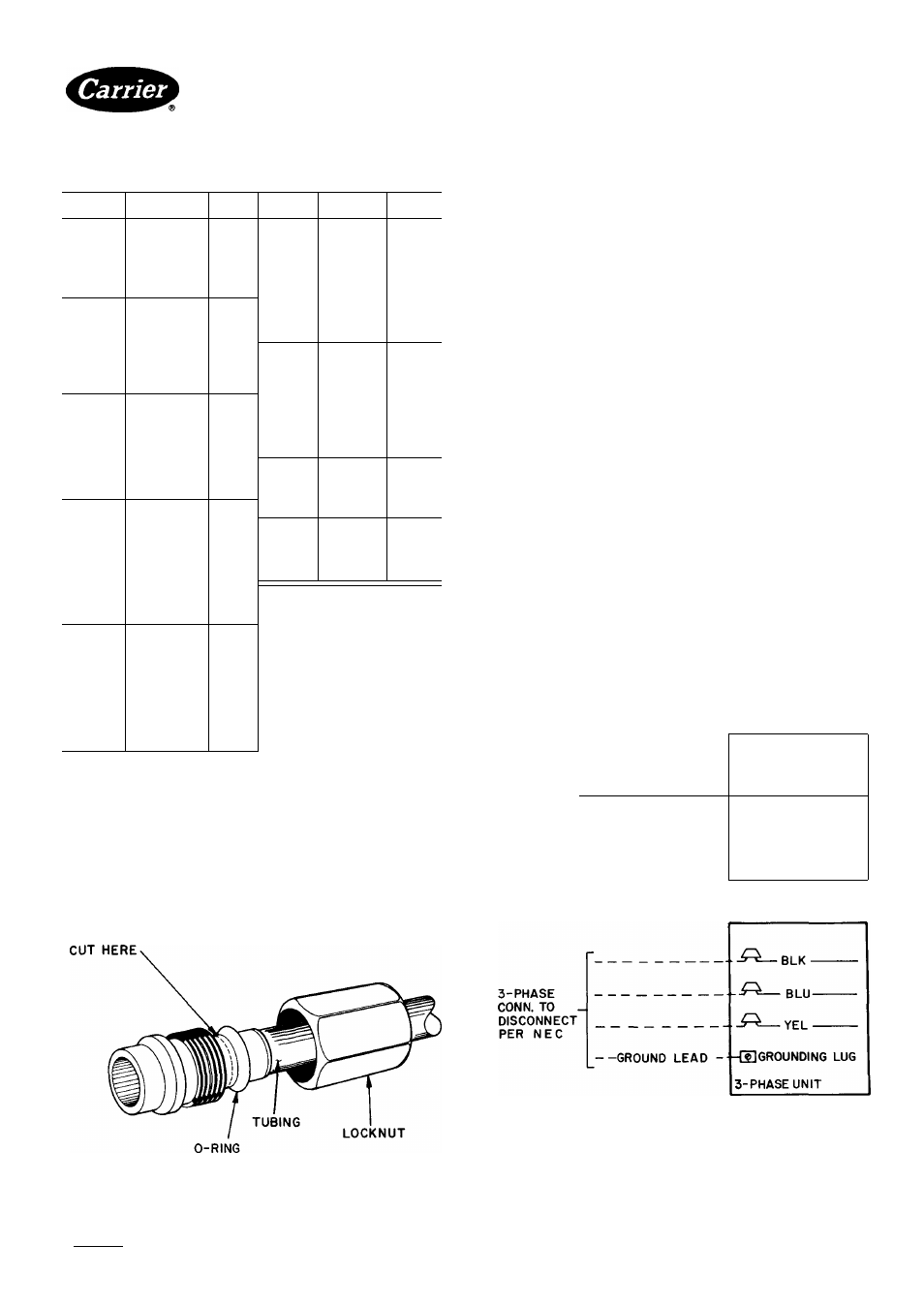

Step 4 — make electrical connections — be, Table 2 — accurater™ selection charts, Fig. 3 — compatible fitting – Carrier 38QH User Manual

Page 3: Fig. 4 — line power connections

Attention! The text in this document has been recognized automatically. To view the original document, you can use the "Original mode".

HEATING A COOLING

38QH

Heat Pumps — Outdoor Section

Table 2 — AccuRater™ Selection Charts

OUTDOOR

INDOOR

INDOOR

OUTDOOR

INDOOR

INDOOR

UNIT 38QH

UNIT

PISTON

UNIT 38Qh

UNIT

PISTON

28AC015

49‘

28AC.AU042

80*

28AC.AU018

49’

28AC242

80*

28HQ.VQ024

49*

28AC.AU048

82*

015

40AQ018

46

28AC248

82*

(35)t

40AQ024

49*

28AM048

82

40DQ014

46*

842

(73)t

28HQ.VQ042

76

40DQ018

46*

28HQ.VQ048

80*

40DQ024

49

28HQ.VQ060

28SL042

82*

76*

28AC.AU018

52*

28AC.

au

,AM024

28HQ.VQ024

55*

52*

28SL060

82*

018

(42)t

28HQ.VQ030

40AQ018

40AQ024

55*

49*

52

40QB.QH048

82

28AC.AU048

84

40AQ030

55*

28AC248

84

40DQ018

49*

28AC.AU060

86*

40DQ024

52*

28AC260

86*

40DQ030

55*

28AM048

84*

024

(52)t

28AC,AU,AM024

28AC.AU030

28AM036

28HQ.VQ024

28HQ.VQ030

28HQ.VQ036

40AQ024

40AQ030

61*

63*

63*

59*

61*

63*

59*

61’

048

(73)t

28HQ.VQ048

28HQ.VQ060

28SL048

28SL060

40QB048

40QB.QH060

40QB.QH062

82*

84*

82

84*

84*

86*

86*

28AC.AU060

101*

40AQ036

63*

28AC260

101*

40DQ024

59

060331

28HQ.VQ060

98*

40DQ030

61*

(78)t

28SL060

98*

28AC.AU030

28AC.AU036

28AC236

70*

73

40QB,QH060

40QB.QH062

101*

101*

73

28AC.AU060

93*

28AM036

70*

28AC260

93*

28HQ.VQ030

67*

060341

28HQ.VQ060

90*

030

(59)t

28HQ.VQ036

70*

(78)t

28SL060

90*

28HQ.VQ042

73*

40QB.QH060

93

28SL030

28SL036

67*

70*

40QB.QH062

93

28SL042

73*

40AQ030

67*

40AQ036

70*

40DQ030

67*

28AC.AU036

73

28AC236

73

28AC.AU042

73’

28AC242

73*

28AM036

70*

036

(61 )t

28HQ.VQ036

70*

28HQ.VQ042

73*

28HQ.VQ048

73*

28SL036

70*

28SL042

73*

28SL048

73*

40AQ036

70*

40QB042

73’

'Replace factory-installed piston with this piston size

fRequired outdoor piston size

Step 4 — Make Electrical Connections — Be

sure field wiring complies with local and national fire,

safety and electrical codes, and voltage to system is within

limits shown in Table 3. Contact local power company

for correction of improper line voltage.

NOTE: Operation of unit on improper line voltage con

stitutes abuse and could affect Carrier warranty. See

COMPATIBLE FITTING

Table 3. Do not install unit in system where voltage may

fluctuate above or below permissible limits.

See Table 3 for recommended fuse sizes. When making

electrical connections, provide clearance at unit for refrig

erant piping connections.

INSTALL BRANCH CIRCUIT DISCONNECT PER

NEC of adequate size to handle unit starting current.

Locate disconnect within sight from and readily access

ible from unit, per Section 440-14 of National Electrical

Code (NEC).

ROUTE LINE POWER LEADS — Extend leads from

disconnect through power wiring hole provided (see

Fig. 1) and into unit splice area. Remove control box

cover to gain access to unit wiring.

CONNECT GROUND LEAD AND POWER WIRING

— Connect ground lead to ground connection in control

box for safety. Then connect power wiring. See Fig. 4.

Splice line power leads to yellow and black pigtails. Use

wire nuts and tape at each connection. Connect unit

wiring to copper power wiring only.

CONNECT CONTROL POWER WIRING — Route

24-v control wires through control wiring hole and

channel and eonnect leads to control wiring terminal

board. See Fig. 1 and 5.

Use furnace or fan coil transformer as 24-v (40-va

minimum) supply for system as shown in Fig. 5, or use

accessory transformer (refer to Service data).

I-PHASE

CONN. TO

DISCONNECT

PER NEC

-------- GROUND LEAD-

-IU

grounding

lug

_----------------------------------

— YEL

1- PHASE

UNIT

Fig. 3 — Compatible Fitting

^

Splice Connections

_________ Field Wiring

---------------- Factory Wiring

Fig. 4 — Line Power Connections

Manufacturer reserves the right to discontinue, or change at any time, specifications or designs without notice and without incurring obiigations.

Book|1 14

PC101

Catalog No 533-808

Printed in U.S A

Form38QH-2SI

Pg 3

7-85

Replaces: 38QH-1 SI

Fnr ronlnrAmAnl Home tieo f^orrior fino/^ilioH Dorte

Tah IRaIRa