A caution, Compatible fitting repair – Carrier 38QH User Manual

Page 2

Attention! The text in this document has been recognized automatically. To view the original document, you can use the "Original mode".

HEATING & COOLING

38QH

Heat Pumps.^^utdoor Section

Table 1 — Physical Data

MODEL 38QH

015

018 024 030 036 042 048

060

OPER WT (lb)*

132

145

180

195

195

235

235

270

REFRIGERANT

Control

COND FAN

Air Discharge

AirQty (Cfm)

Mtr Rpm (60 Hz)

COND COIL (FIn/in.)

Tube Diam

Rows

Refrig Ckts

Face Area (sq ft)

Outer Row

Inner Row

DIMENSIONS (ft-in.)

Diameter

Height

CONNECTIONS (in. ODF)

Suction

Liquid_________________

REFRIG LINES (in. ODF)

Suction

Liquid________________

22

AccuRater” (Bypass Type)

Propeller Type, Direct Drive

Vertical

1850 I 3100 I 4000

15000

830

850

840

17.11

2188

17.11

21.88

3-2'/2

Compatible Fitting (Suction)

& Flare (Liquid)

1

y4

%

I'/at

*Add 10 lbs for louvered casing (if so equipped). Weight increases slightly

with addition of any accessories

t38QFI042-060 require 1’/e-in. suction line for optimum performance. A

%- X I'/a-in connection adapter accessory (Carrier Part No 28AU900061)

is available. If a 7e-ln accessory tubing package is used, expect a 2'/2%

capacity loss

A

CAUTION

DO NOT BURY MORE THAN 3 FT OF REFRIG

ERANT TUBING IN GROUND. If any section of

tubing is buried, there must be a 6-in. vertical rise to

valve connections on outdoor unit. If more than the

recommended length is buried, refrigerant may

migrate to cooler buried section during extended

periods of unit shutdown. This causes refrigerant

slugging and possibly compressor damage at start-up.

CONNECT REFRIGERANT LINES to fittings on out

door unit suction and liquid service valves (Fig. 1). Unit

Compatible Fittings permit mechanical (quick-connect)

or sweat connections.

Models 38OH042,048,060 — When using 1 -1 /8 in. field-

supplied refrigerant suction line, sweat-connect suction

line to 1-1/8 in. end of required connection adapter. Be

sure to provide a heat sink at the service valve to prevent

damage during sweating operation. Connect 3/4-in. end

of adapter to unit suction line Compatible Fitting.

Connect liquid refrigerant line to unit. When a 7/8-in.

field-supplied suction line is used, provide a field-supplied

3/4-in. to 7/8-in. suction line adapter (not necessary if

38LS accessory tubing is used).

Mechanical Connection — Mate one set of connections at

a time.

1. Loosen nut on Compatible Fitting one turn. Do not

remove.

2. Remove plug and be sure O-ring is in the groove inside

the Compatible Fitting.

3. Cut tubing to correct length. Deburr and size as

necessary.

FLARE NUT

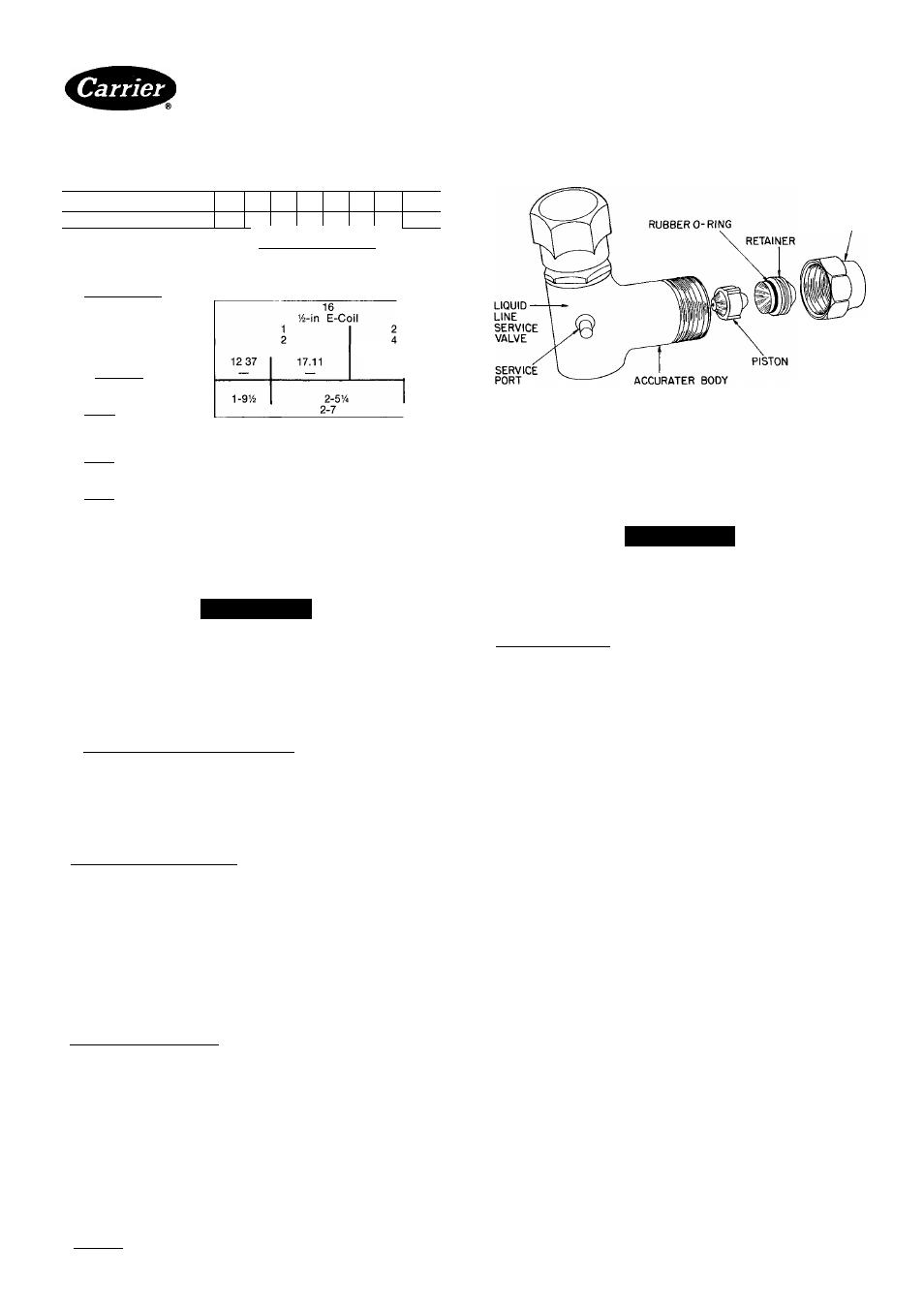

Fig. 2 — AccuRater (Bypass Type) Components

4. Insert tube into Compatible Fitting until it bottoms.

Tighten nut until it bottoms on shoulder of fitting or

valve. Keep tube bottomed in Compatible Fitting

while tightening nut.

A

CAUTION

If undersized, damaged or elliptically-shaped

tubing is used when making Compatible Fitting,

leaks may result.

Sweat Connection— Use refrigerant grade tubing.

1. Remove locking nut, rubber O-ring and Schrader core

and cap from valve service port.

2. Cut tubing to correct length. Deburr and size as

necessary.

3. Insert tube in Compatible Fitting until it bottoms.

NOTE: Wrap top and bottom of service valves in wet

cloth to prevent damage by heat. Solder with low-

temperature 430 F silver alloy solder.

4. Replace Schrader core and cap.

5. Evacuate or purge system with field-supplied

refrigerant.

Compatible Fitting Repair

MECHANICAL CONNECTION — Frontseat unit

service valves. Relieve refrigerant pressure from tubing.

Back off locknut from Compatible Fitting onto tube. Cut

fitting between threads and O-ring. See Fig. 3. Remove

tubing section remaining in threaded portion of fitting.

Discard locknut.

Clean, flux and insert new tube end into remaining

portion of Compatible Fitting. Wrap valve in wet rag to

prevent damaging factory-made joints. Heat and apply

low-temperature (430 F) solder.

SWEAT CONNECTION — Frontseat unit service

valves. Relieve refrigerant pressure from tubing. Clean

and flux around leak. Repair, using low-temperature

(430 F) solder. Evacuate or purge evaporator coil and

tubing system. Add refrigerant charge. Refer to Table 5.

©

Manufacturer reserves the right to discontinue, or change at any time, specifications or designs without notice and without incurring obligations.

Book| 1 |4

PC101

Catalog No 533-808

PrintedinUSA

Form38QH-2SI

Pg 2

7-85

Replaces: 38QH-1 SI

X aK IAaIRa

For r<»nlacement items use Carrier Soecified Parts