Start-up, adjustment, and safety check, Gas input, A caution – Carrier 58SX040 User Manual

Page 6

Attention! The text in this document has been recognized automatically. To view the original document, you can use the "Original mode".

START-UP, ADJUSTMENT, AND

SAFETY CHECK

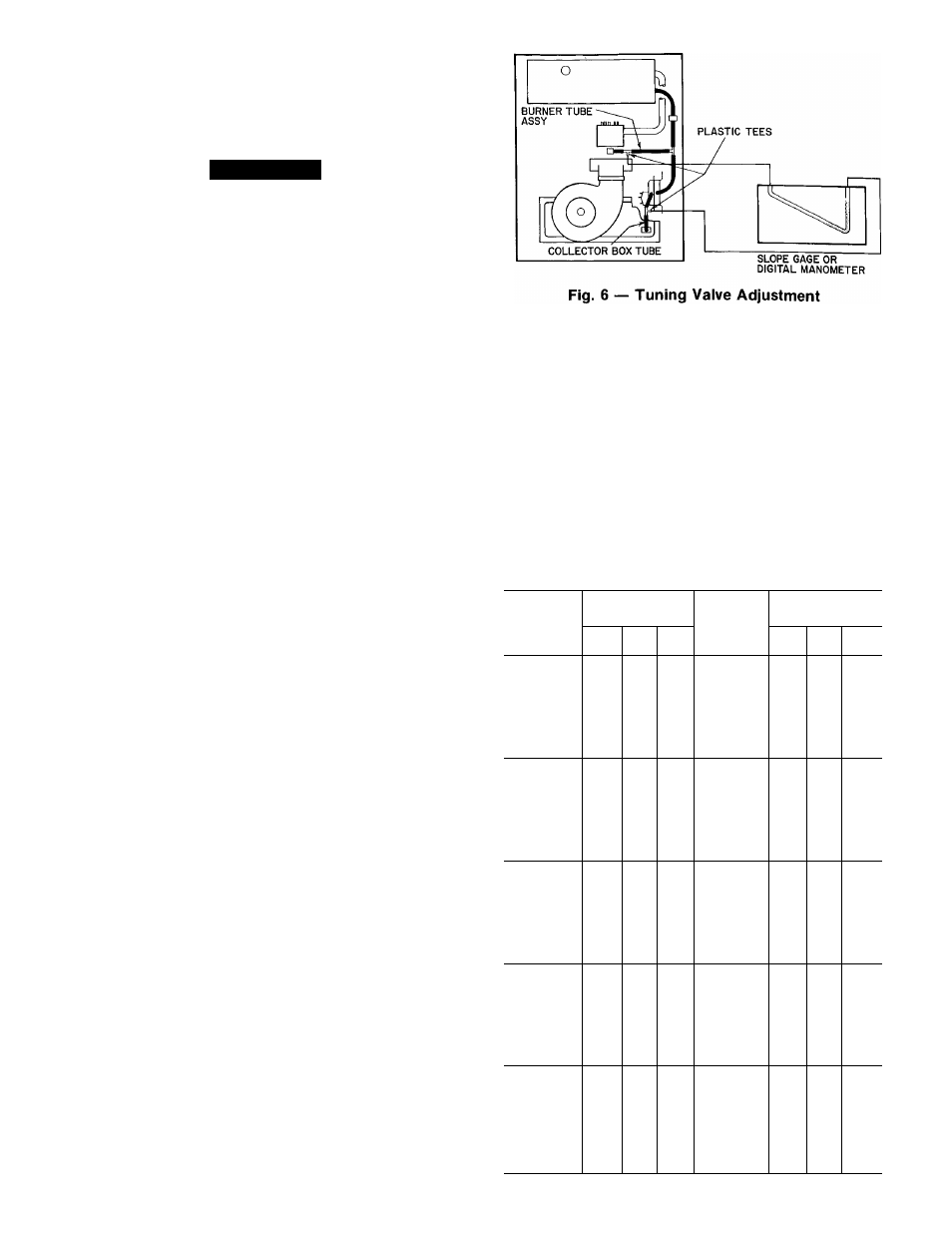

Adjusting Tuning Valve — Before firing the furnace,

adjust the pressure drop through the heat exchanger for

maximum efficiency, following the steps below

A CAUTION

Be sure gas supply to furnace is turned off.

1, Install field-supplied plastic tee between pressure tap

on bottom of gas valve and pressure tube as shown

in Fig. 6.

2

Install second field-supplied plastic tee between

pressure switch and pressure tube from collectoi box

See Fig 6.

3 Connect slope gage to tees (Fig. 6)

4. Close R-W circuit to start inducer motor.

5. Adjust tuning valve to obtain 0.83 ± 0 01 in negative

water column.

6 Remove handle from tuning valve and recheck pres

sure. Store handle in safe place.

7. Open R-W circuit.

8 Disconnect slope gage

9. Remove plastic tees and reconnect factory pressure

tubes to gas valve and pressure switch.

10 Turn on gas supply to furnace

Ignition System Check — When all connections

have been checked, light the furnace using procedure

outlined on lighting instruction plate attached to furnace

When lighting the furnace for the first time, however,

perform the following additional steps

1 If gas supply was not purged before connecting

furnace, line will be full of air Loosen ground joint

union and allow supply line to purge until gas odor is

detected. Neva purge gas lines into a comhustion

chamber. Immediately upon detection of gas odor,

retighten union. After 5 minutes, light furnace in

accordance with instructions on furnace rating plate.

2 Main burners should light 25 to 75 seconds after pilot.

If main burners do not light within prescribed time

period, adjust pilot flame, allow pilot to cool for

5 minutes, and repeat time check (Fig. 7).

3 Locate pilot adjusting screw on top of valve;

a. Remove cap screw, turn pilot adjusting screw

counterclockwise to decrease burner-on time delay,

or clockwise to increase burner-on time delay.

b. Replace cap screw.

Gas Input

NOTE: Be sure reference pressure tube, combustion-air

and vent pipes, and burner enclosure front are in place

when clocking the gas meter.

1. Deteimine gas input.

a. Turn off all other gas appliances and pilots

b. Measure time (in seconds) for gas meter test dial to

complete one revolution

c Refer to Table 4 for cu ft of gas per hour,

d. Multiply cu ft/ hr by heating value of gas (Btu/ cu ft)

obtained from local gas utility.

EXAMPLE

Btu heating input = Btu/cu ft times cu ft/hr

Heating value of gas = 1070 Btu/cu ft

Time for one revolution of 2-cu-ft dial = 72 sec

Gas rate = 100 cu ft/hr (frbm Table 4)

Btu heating input = 107() x 100 = 107,000 Btuh

e. Measured gas input must not exceed gas input on

unit rating plate.

2. To adjust input rate:

a.

Remove burner enclosure front and cap that

conceals adjustment screw for gas valve regulator.

b. Turn adjusting screw either counteiclockwise (out)

to decrease input rate or clockwise to increase rate.

When adjusting input rate, do NOT change mani

fold pressure more thanO.3 in wg. Make any major

adjustments by changing main burner orifices

(Fig. 7).

Table 4 — Gas Rate in cu ft/hr

SECONDS

FOR ONE

REVOLU

TION

SIZE OF

TEST DIAL

SECONDS

FOR ONE

SIZE OF

TEST DIAL

1

cu ft

2

cu ft

5

cu ft

REVOLU

TION

1

cu ft

2

cu ft

5

cu ft

10

360

720

1800

50

72

144

360

11

327

655

1636

51

71

141

355

12

300

600

1500

52

69

138

346

13

277

555

1385

53

68

136

340

14

257

514

1286

54

67

133

333

15

240

480

1200

55

65

131

327

16

225

450

1125

56

64

129

321

17

212

424

1059

57

63

126

316

18

200

400

1000

58

62

124

310

19

189

379

947

59

61

122

305

20

180

360

900

60

60

120

300

21

171

343

857

62

58

116

290

22

164

327

818

64

56

112

281

23

157

313

783

66

54

109

273

24

150

300

750

68

53

106

265

25

144

288

720

70

51

103

257

26

138

277

692

72

50

100

250

27

133

267

667

74

48

97

243

28

129

257

643

76

47

95

237

29

124

248

621

78

46

92

231

30

120

240

600

80

45

90

225

31

116

232

581

82

44

88

220

32

113

225

563

84

43

86

214

33

109

218

545

86

42

84

209

34

106

212

529

88

41

82

205

35

103

206

514

90

40

80

200

36

100

200

500

92

39

78

196

37

97

195

486

94

38

76

192

38

95

189

474

96

38

75

188

39

92

185

462

98

37

74

184

40

90

180

450

100

36

72

180

41

88

176

439

102

35

71

178

42

86

172

429

104

35

69

173

43

84

167

419

106

34

68

170

44

82

164

409

108

33

67

167

45

80

160

400

110

33

65

164

46

78

157

391

112

32

64

161

47

76

153

383

116

31

62

155

48

75

150

375

120

30

60

150

49

73

147

367