Carrier 58SX040 User Manual

Page 4

Attention! The text in this document has been recognized automatically. To view the original document, you can use the "Original mode".

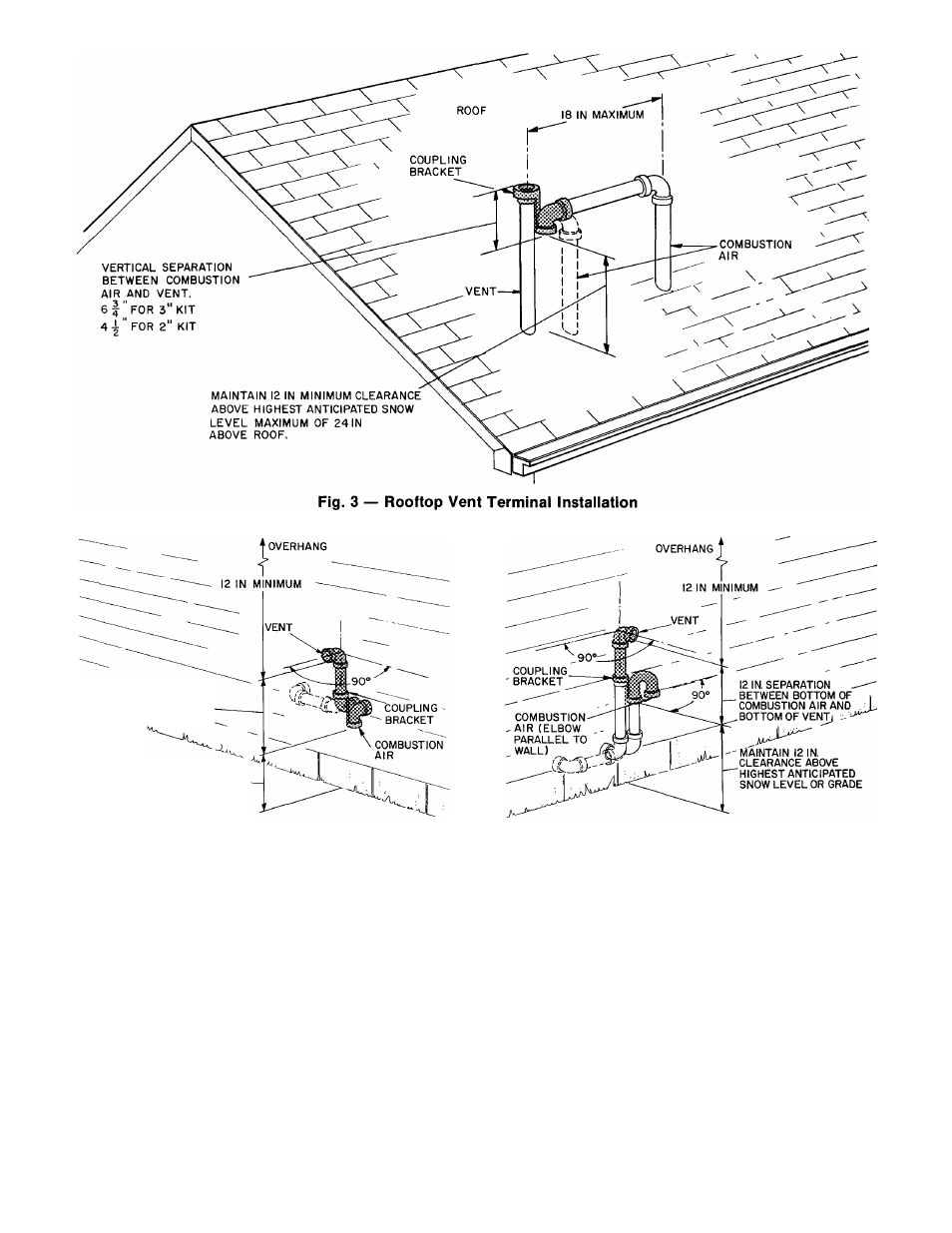

' 12 IN SEPARATION

, BETWEEN BOTTOM OF

i. COMBUSTION AIR AND

BOTTOM OF VENT --

MAINTAIN 12 IN. CLEARANCE

ABOVE HIGHEST ANTICIPATED

SNOW LEVEL OR GRADE

Fig. 4 — Sidewall Vent Terminal Installation

(12 in. above snow level or grade)

Fig. 5 — Sidewall Vent Terminal Installation

(less than 12 in. above snow level or grade)

7. After pipes have been cut and preassembled, apply

generous layer of PVC primer to pipe fitting socket

and end of pipe to insertion mark. Quickly apply

PVC cement (over primer) to end of pipe and fitting

socket. Apply cement in light, uniform coat on inside

of socket to prevent buildup of excess cement. Apply

second coat of cement to end of pipe.

8 While the PVC cement is still wet, insert pipe into

socket with a I/4-turn twist. Be sure pipe is fully

inserted into fitting socket

9. Wipe excess cement from joint. A continuous bead

of cement is visible around perimeter of a properly

made Joint.

10. Handle pipe joints carefully until cement sets.

11. Support piping every 5 ft (minimum) using per

forated metal hanging strap. Slope combustion-air

and vent pipes toward furnace a minimum of 1 /4-in./

lineal ft with no sags between hangers.

12 Use appropriate methods to seal openings where vent

and combustion-air pipes pass through roof or

sidewall

Vent Terminal Kit Installation — The combustion-

air and vent pipes must terminate outside the structure.

The Carrier accessory vent termination kit for 2-in.

diameter pipe (required) must be installed as shown in

Fig. 3, 4 or 5. Roof termination, shown in Fig. 3, is pre

ferred. The kit contains extra parts for the various

applications.

NOTE: The shaded portions of Fig. 3, 4 and 5 are con

sidered part of the vent terminal and are provided in the

vent terminal kit. They should not be counted, therefore,

in pipe diameter calculations.