Fig. 8 — timer sequence chart – Carrier 38AE User Manual

Page 7

Attention! The text in this document has been recognized automatically. To view the original document, you can use the "Original mode".

Head Pressure Control

by means of/an

cycling is a

standard feature of 38AE012-016 units. The no. 2 fan cy

cles in response to changes in liquid pressure. The switch

cycles the fan off at 126 ± 4 psig (869 ± 28 kPa) as pres

sure decreases, and cycles back on at 257 (-1-5, -0) psig

(1772 [-f 103, -0] kPa).

CONTROL

SET POINT

ADJUSTMENT

NUT

PRESSURE

DIFFERENTIAL

ADJUSTMENT

SCREW

VALVE BODY

BYRASS

PISTON

DIFFERENTIAL SCREW'

SEALING CAP

(CAP MUST BE REPLACED

TO PREVENT REFRIGERANT LEAKAGE)

Fig. 7 — Compressor Capacity Controi Unloader

Time Guard® II Circuit

provides for a delay of ap

proximately 5 minutes before restarting compressor after shut

down from safety device action.

On start-up, the Time Guard II timer causes a delay of

approximately 3 seconds after thermostat closes.

On compressor shutdown, the timer recycles for approx

imately 5 minutes. During this time, the compressor cannot

restart.

Refer to Fig. 8 and to label diagram on unit.

TIME DELAY TIMING SEQUENCE

T1-T2

---------- RUNNING TIME---------- »■

p«------ 3SEC ------------------------- »■

5 MIN

wimmmmmmimiri.

WIA

DENOTES CLC6ED CONTACTS

Fig. 8 — Timer Sequence Chart

Winter-Start Control (If Required)

- install Ac

cessory Package 38AE900021.

Crankcase Heater

prevents refrigerant migration and

compressor oil dilution during shutdown whenever com

pressor is not operating. It is wired into the control circuit,

cycling with the compressor, off when compressor is run

ning, and on when compressor cycles off.

Both compressor service valves must be closed when

ever crankcase heater is deenergized for more than 6 hours.

The crankcase heater is operable as long as the control cir

cuit is energized.

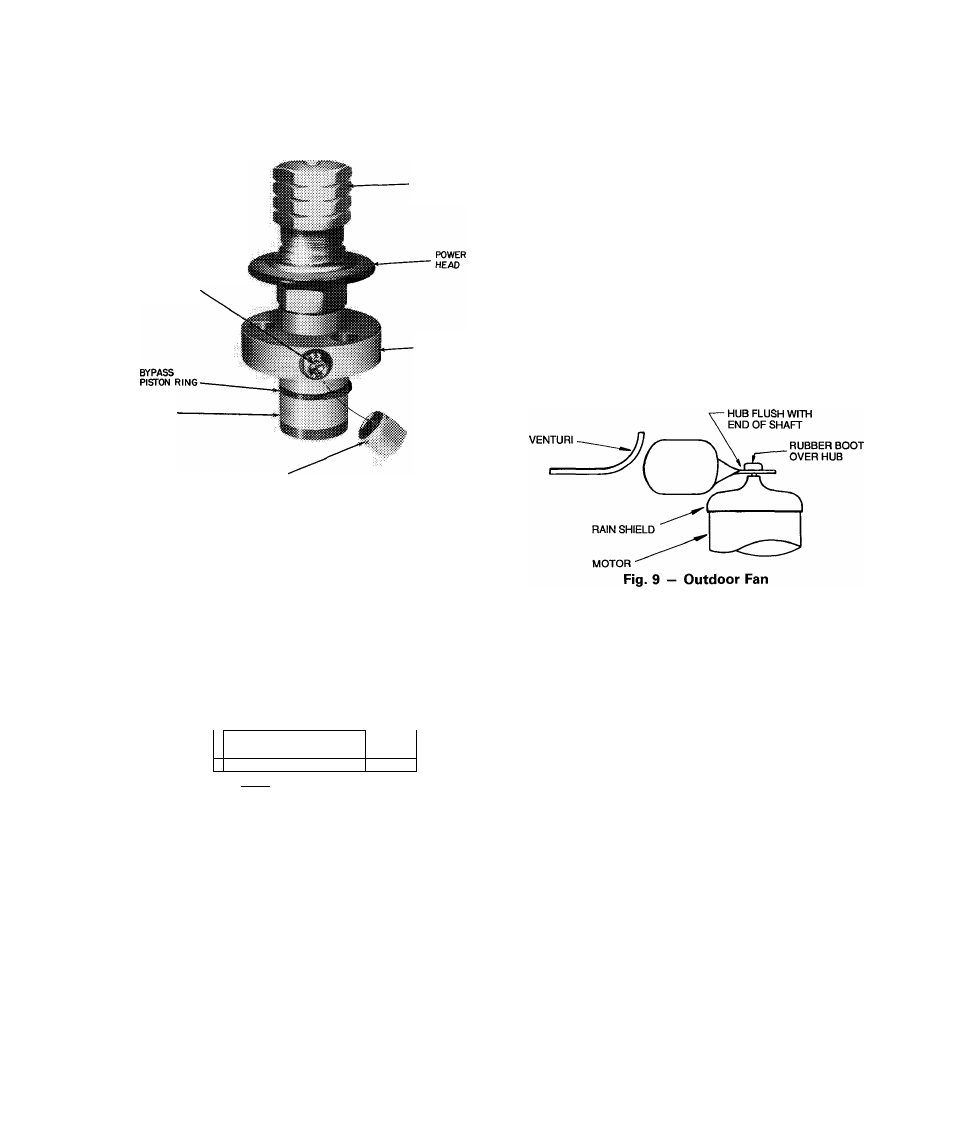

Outdoor Fans

— Each fan is supported by a formed-

wire mount bolted to the fan deck and covered with a wire

guard. The exposed end of the motor shaft is covered with

a rubber boot. In case a fan motor must be repaired or re

placed, be sure the rubber boot is put back on when the fan

is reinstalled and be sure the fan guard is in place before

starting the unit. Figure 9 shows the proper position of the

mounted fan. Fan motors have permanently lubricated

bearings.

Lubrication

FAN MOTORS have sealed lubrication bearings. No pro

visions for lubrication are made.

COMPRESSOR has its own oil supply. Loss of oil due to a

leak in the system should be the only reason for adding oil

after the system has been in operation. See Oil Charge

section.